I'm going to quote myself from a recent thread where a newb asked about foamies:

"...a basic foamie is built using expanded (those little balls squeezed together) or extruded (the blue and pink construction board) polystyrene foam as a core material with a canvas (or other cotton fabric) outer skin that is adhered using glue or paint. Once adhered, the canvas weave is saturated with more paint, similar to a glass composite construction.

The inner panels can be skinned the same way; with chip board (single ply paper box); or with thin ply (hybrid). Variations include using epoxy and glass for the skins, and using more wood inside (in my mind, a hybrid).

The key is to minimize the amount of wood. Basic foamies, like GPW's little camo 4wide, and Eaglesdare's Mickey have very little wood, just some hard points around the doors, are quite basic, easy to build, and can generally cost less than a more traditional build with more features.

Atahoekid's Road Foamie has epoxy and glass skin, and IIRC, wooden cabinets. Mine has a lot of wood in the cabinets with wood inner skins (The Poet Creek Express link in my signature below). Some people even use the canvas skin over plywood outer walls, but those aren't true foamies; that is more of variation on a 'traditional' instead of using aluminum skins.

Everything you ever want to know about foamies can be learned from reading The Big Thrifty Thread, but be forewarned it is a monster and comes with a separate index thread to help navigate through it."

GPW's FoamStream build is here (I refer to him as "The Godfather of the Modern Foamie Movement".

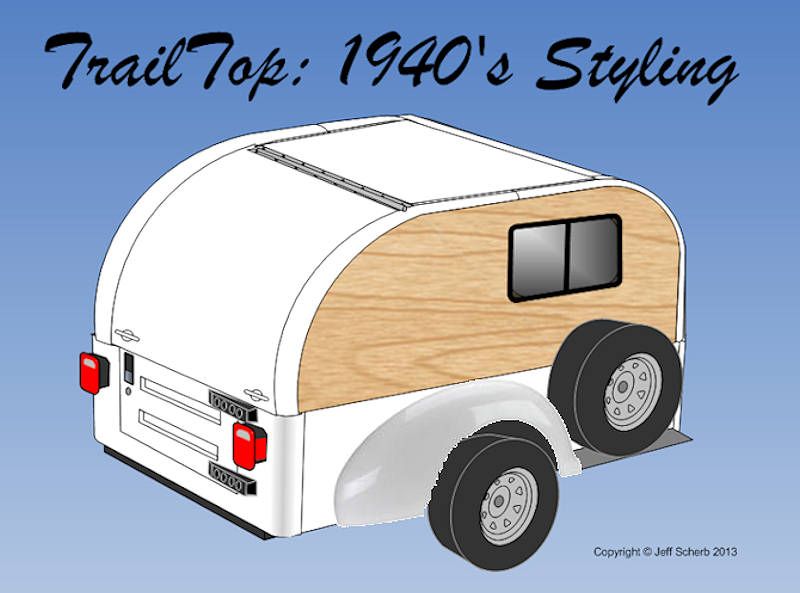

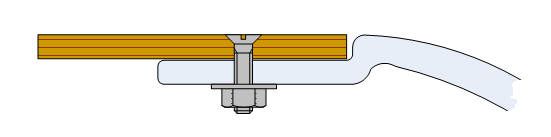

"TrailTop" modular trailer building components

Re: "TrailTop" modular trailer building components

KC

My Build: The Poet Creek Express Hybrid Foamie

Poet Creek Or Bust

Engineering the TLAR way - "That Looks About Right"

TnTTT ORIGINAL 200A LANTERN CLUB = "The 200A Gang"

Green Lantern Corpsmen

My Build: The Poet Creek Express Hybrid Foamie

Poet Creek Or Bust

Engineering the TLAR way - "That Looks About Right"

TnTTT ORIGINAL 200A LANTERN CLUB = "The 200A Gang"

Green Lantern Corpsmen

-

KCStudly - Donating Member

- Posts: 9613

- Images: 8169

- Joined: Mon Feb 06, 2012 10:18 pm

- Location: Southeastern CT, USA

Re: "TrailTop" modular trailer building components

KCStudly wrote:"...a basic foamie is built using expanded (those little balls squeezed together) or extruded (the blue and pink construction board) polystyrene foam as a core material... Everything you ever want to know about foamies can be learned from reading The Big Thrifty Thread, but be forewarned it is a monster and comes with a separate index thread to help navigate through it."

GPW's FoamStream build is here (I refer to him as "The Godfather of the Modern Foamie Movement".

Thanks. Lots of reading material! I'll check it out.

- jscherb

- The 300 Club

- Posts: 388

- Joined: Sat Dec 24, 2011 8:27 am

- Location: Elmira, NY

.

.

not sure what that leaves for a market considering that it will be sold to DIYers. The majority is more likely to find their own, more thrifty way.

not sure what that leaves for a market considering that it will be sold to DIYers. The majority is more likely to find their own, more thrifty way.  ...!

...!