S. Heisley wrote:Hi, stomperxj:

Your build really shows your knowledge and skills. You're doing a beautiful job!If only we all were as capable as you!

As I was looking at your battery box and the underside of the deck, I noticed that the trailer appears to not have a water shield to protect all your hard work. Obviously, you are building this extra tough so it can handle rugged terrain and you will probably be fording some streams and occasionally will be in rain and/or snow; so, you probably have a plan that just isn't evident yet. (Please forgive me if I missed something in the 8 pages of build pictures and notations.)

What is your plan for the subflooring water shield? Are you going to lift the body above the metal chassis so you can get at the underside of all the deck plywood? Are you going to apply roof emulsion or you do you plan to use the Kilz listed in your spreadsheet or.....?

OOPS!Scratch the above. I went back and found the picture where you coated the floor; but, I don't understand why that black coating doesn't show in the pictures of the underside of the installed battery box. Isn't that built into the deck floor?

Hey Sharon - Good questions and thanks for the compliments. Hard to believe this is my first real wood working project. I'm just taking my time and I designed it around the tools I have available to me. I want it to be bullet proof too

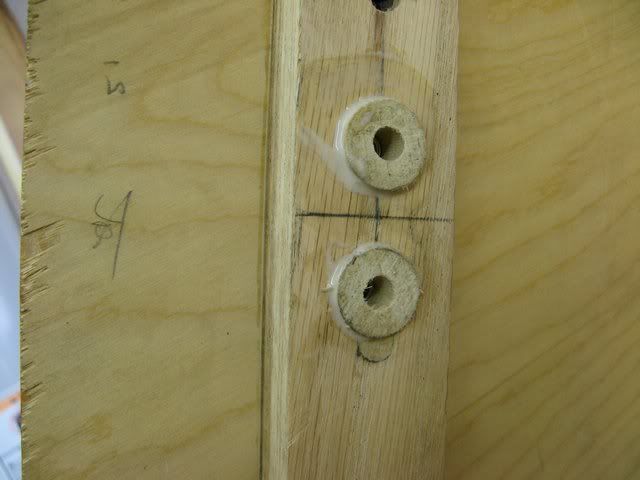

I did coat the underside of the subfloor with some Duplicolor bedliner at one point. Then I decided that 1/2" CDX was about the crappiest wood ever made so I pitched that subfloor and rebuilt a new subfloor out of 3/4" ACX. My plan is to lift the body off of the frame and coat the whole exterior and underside with CPES and then Kilz the whole underside too. Hopefully that will keep the water at bay. I lifted the body off of the frame one end at a time the other day to trim the bottom edges and repaint part of the frame. It is lighter than I thought it was going to be. I can pick up half the body by myself...

All I need now is money

Thank you!

Thank you!