Small Travel Trailer Frame Design Question

31 posts

• Page 1 of 3 • 1, 2, 3

Small Travel Trailer Frame Design Question

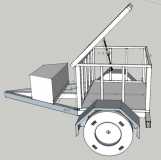

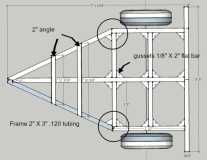

I'm attempting my first trailer frame build and am concerned my design has a couple of weak spots but don't see a good solution. The intent is simply to enlarge cargo space with a 4' W, 3' D, 2' H cargo box that can carry camping supplies and the like. The overall length is just over 7' and the frame is 4' wide. It is also designed to carry a medium sized tongue box. The tongue consists of a single member extending the entire length of the trailer and two side rails to stiffen it. My concern is the joint where the side rails join the box frame. I've changed the original design to where i'm mitering a single length of tube to extend from the nose back to form the rail the axle spring will mount to. My thought is to plate the mitered joint on three sides with 1/4" plate (shown in illustration.) I also intend to put 14 gauge sheet as the floor in the trailer and the box will be built on top of it. For the box i'm using 1" X 1" .063 square tubing with the addition of 1" X 2" at corners and for the lid framing. the following images are the work in progress. i'm guessing the weight of the trailer around 450 lbs with a 1000 lb. payload max. any thoughts are appreciated..

- jerlands

- Teardrop Inspector

- Posts: 17

- Images: 7

- Joined: Sat May 23, 2020 4:38 am

- Location: Pioneer Ca

Re: Small Travel Trailer Frame Design Question

Well, I'm only an "eyeball engineer", so this is all opinion.

If it's an all welded structure, and the gussets and plating aren't bolted on, I wouldn't hesitate to pull it behind my truck. I think your plating could be reduced to .120" and still have the strength needed for the joint, especially as you're pie-cutting that rail, instead of a full angled cut and (essentially) butt welding the ends back together.

Personally, I don't care for the rather short length, as it's going to get critical for weight and balance loading. Get a bit too much aft of the axle, and your tongue weight is going to go away pretty quick. Backing up with that short of a trailer is going to get tricky, too. It'll jack knife on you in a hurry.

Don't scrimp on the lighting. There's too many "drivers" out there today that aren't paying attention to what's going on around them.

Roger

If it's an all welded structure, and the gussets and plating aren't bolted on, I wouldn't hesitate to pull it behind my truck. I think your plating could be reduced to .120" and still have the strength needed for the joint, especially as you're pie-cutting that rail, instead of a full angled cut and (essentially) butt welding the ends back together.

Personally, I don't care for the rather short length, as it's going to get critical for weight and balance loading. Get a bit too much aft of the axle, and your tongue weight is going to go away pretty quick. Backing up with that short of a trailer is going to get tricky, too. It'll jack knife on you in a hurry.

Don't scrimp on the lighting. There's too many "drivers" out there today that aren't paying attention to what's going on around them.

Roger

- GTS225

- Teardrop Master

- Posts: 299

- Joined: Wed Aug 29, 2018 2:11 am

- Location: Waterloo, Iowa