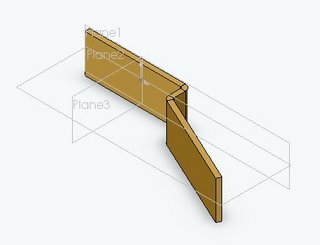

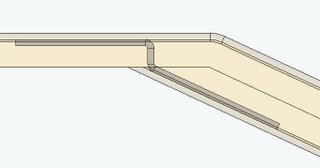

This is bar channel with a uniform thickness in the legs.

If I had to use standard channel, which have a tapered thickness in the legs, I think I would use something else.

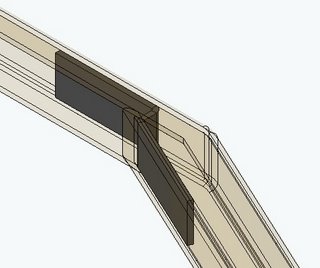

The frame is made completely from channel except two mounting plates that are 11 gage or .1196 in thickness. I will have to weld two additional channel pieces to the tongue to make tubes for strength. I am not sure yet the strength of two of these channels welded into a box, but I think that because of the channel’s profile it will prove to be stronger than standard tubing.

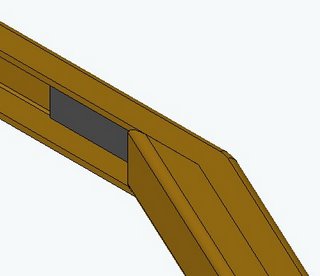

The outside tongue channel runs from the coupler to the end of the frame. It is one continuos piece that will be notched, bent, and welded. The inside tongue channel runs from the coupler into the joint that is created from the bend in the outside channel and welded into place along with the front cross member.

I am no structural engineer and have no trailer building experience; I can however cut and weld as I used to fabricate sheet metal and structural components for a living.

The frame weighs 131.8615 lbs. I don’t know if this is considered heavy or not. The goal I gather is to have a strong but light frame, and I’m sure I’m not doing that. The trailer could grow to somewhere between 1500 and 2000 lbs. I hope it doesn’t and am concerned about the A-frame tongue being adequate. The weight stated does not include the two axle brackets in the drawings. The two channel gussets welded to the tongues forward of the cross brace should not be necessary. That would be nice because there is a lot going on in that area already.

I’m counting on the galley partition to strengthen the floor in the rear. If I find that I need additional floor support it might be in the way of oak lumbar.

Because of the short 2” web height on the channel, I’m worried about the frame twisting. Hopefully between the strength of the cabin box and the axle, this will not be a problem.

I’m sure I didn’t explain this very well, so please ask any questions. It is evident that I don’t know what I’m doing but I want to learn, and I am having fun! I value any and all input. This is just the first brush at a frame and I’m sure it could be simpler. The nice thing about using CAD is that you can play all you want.

Sorry for the book…

Rodger

(Well I had to have a good reason, didn't I?)

(Well I had to have a good reason, didn't I?)