Hey everyone: I got some time today to cut out the aluminum skins for the sides of the "Silver Nugget". I went to Harbor Freight last week end and I bought an electric metal cutting shear. It was on sale and I also had a 20% off coupon. It cost me $36.00. I found it cuts better with WD40 on the blades. I learned this reading on this forum. It would stop cutting, but it flew through the aluminum like butter after the WD40. I had to apply it several times on each cut.

I had made an 1/8" template pattern when I made the the side walls earlier in my build. It came in handy for setting up the cut lines on the skins.

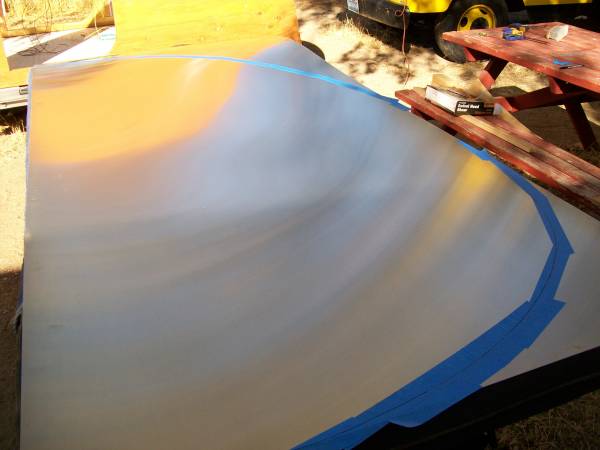

This is how they turned out...

I just have the skins taped in place so I could snap a couple of pics. I almost can't believe it has aluminum on it.

Next, if I have enough time today, is to cut out the door openings and the holes for the wires for the porch lights. I placed everyone's favorite BLUE TAPE by the door openings and traced the shape on the aluminum from the inside of each opening. I know I will get accused of using up all of the BLUE TAPE and that will cause them to raise the cost of it, LOL.

I hope you all are having a great week end !!!