Trying to finish the build before school started up was definitely wish full thinking! As predicted, the engineering school workload is starting to pile up so I am limited to just weekends now. Regardless, I am very excited about putting my teardrop back together after three weeks of taking it apart to finish the wood!

Last Saturday was a big day! I sprayed the interior of the walls, both sides of the bulkhead and the floor finished with water based poly. Because of a rain threat I set up a "spray booth" in the garage this time.

I sprayed everything with five coats because I had the time! Most of the floor will be covered with an automotive style carpet but I decided to go ahead and spray it to help prevent any water from seeping in.

Along with screws every 6 inches, I used PL Premium poly glue on the seam between the floor and the walls. This one bead actually did a good job of reaching both sides of the joint.

I am trying to be conscious about the water that may get trapped between the inside and outside door seal and here is some kind of water drainage idea that I am playing with. I am not sure exactly how this will work with the Al skin and trim but I hope to allow any trapped water drip out at the bottom of the door. This may be as simple as leaving a small gap on the outside seal where I made the notches in the door jam. I also made sure that the door jambs got 5 solid coats of poly to help protect from water.

Here is one of the inner door seals after clamping but before spraying.

While waiting on the poly to dry I started re-assembling the cabin cabinets after staining and finishing them two weeks ago! My fiancee is responsible for the awesome door knobs! Its hard to tell from the picture, but they are ceramic and have compasses on them.

Here you can see the electrical panel in the back of the open storage space on cabinet. I am installing a 110 outlet, standard 12v outlet, double usb charger, and a rocker switch for an accent light in the area.

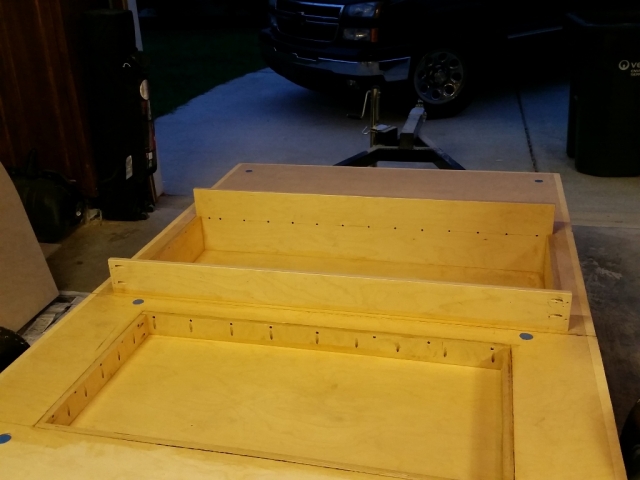

Got them installed! They are held in with probably 30 pocket screws so they shouldn't go anywhere..

Looks like Tiger approves!

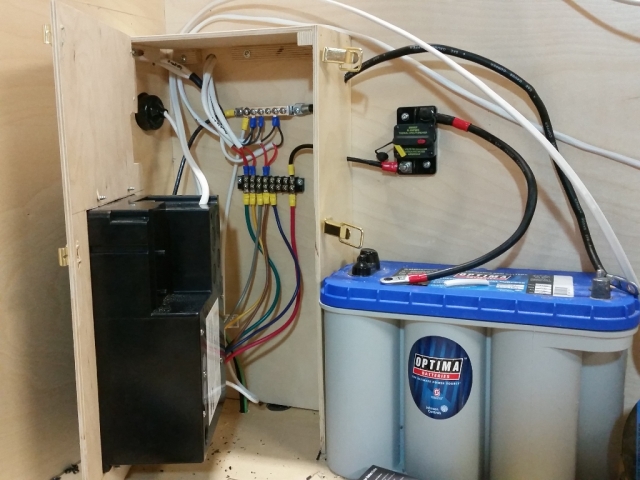

With the walls up, I decided to tackle the power distribution center before I covered it up with the rest of the galley. I don't know why, but this is what happens whenever I work with wires. Soo many pieces..

Here is a closer image of the WFCO 35 amp power center (cover removed) and the wiring behind it. I have a few more circuits to run but this is the bulk of it. You can also see where the 120 is coming though the wall, and heading to the power center. This neat little guy takes care of managing both AC and DC. It has a built in AC breaker panel that protects the converter and allows room for other protected AC circuits. It charges your battery (3-stage), converts plenty of DC when on shore power, and also has 6 protected DC circuits. It is a little overkill for a teardrop, but I was happy to have everything in one place! I also have a 50 amp DC circuit breaker on the hot wire from the battery so I can isolate the power before working on any circuits. I decided to get the biggest blue top that Optima makes. Why not!