I towed it to the marina and, except for the blown flasher relay, it was uneventful. It towed perfectly behind the Ranger and was narrow enough I couldn't see it in the side mirrors. I was running a gear lower on the hills, but it's been a right-lane truck for a long time - left lane for those down under

After moving the trailer, I observed something I thought I'd share.

On a sunny Sunday morning, everyone coming into the marina had to drive by the trailer. Being about 15 degree C and sunny, as one might imagine the marina was pretty busy and I was working away. It seems that every second or third person had to stop and inquire about the trailer. Most of these people are marina regulars I know by sight if not by name so I couldn't really say "bugger off, I'm trying to work" like I do to my nosy drunk neighbour when he sees I'm gloved up for glassing and can't get away.

I'm not sure how many times I related the story of the Benroy trailers or the nature of teardropping (as it seems to me), but it was kind of cool. I have heard (read) that this would happen. When was the last time someone had that interest in a Jayco or a Fleetwood ?

I've had neighbours come around to chat while I'm building and, while polite and friendly, I don't stop what I'm working on and they soon take the hint (aforementioned nosy drunk excepted).

Strangely enough, once I started glassing no one else came around.

Maybe because it was getting late in the afternoon, maybe because I cranked up the stereo in the car, maybe just the styrene wafting on the afternoon breeze ?

More likely they just figured that, since I was wearing a respirator, I was doing something they didn't want any part of. I'll have to try wearing one next time I just don't want to be bothered...like if I'm riding on transit....

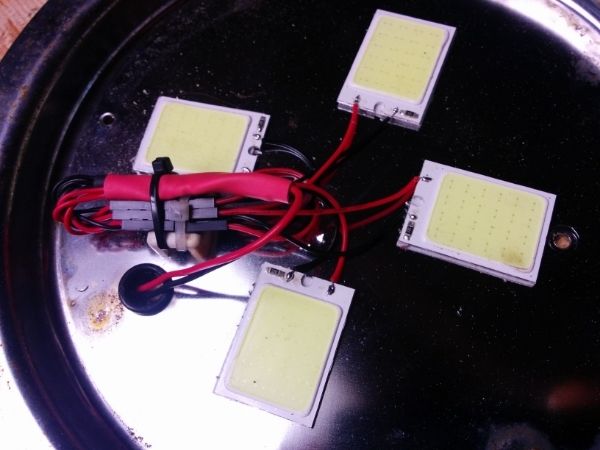

I took the batteries and inverter with me. I rigged them up temporarily and they ran the angle grinder and sander just great, which was good because, in one of my previous battles with fiberglassing in the weather, I hurriedly threw the tarp over fresh glass. It had a ridgepole to keep it up off the roof, but the tarp still hit the roof/wall corner and messed up the still-wet glass. I ground away that mess along both sides so I could redo the corners. That's about when the first round of lookey-loos came by. With the corners ready for glass, I got the next glass job ready so that, once I 'gloved-up', it would be a clear path to glass everything at once and keep the long term nervous system damage to a minimum.

The mess:

In my haste to get the trailer moved, I didn't bother to goop up the bottom of the tongue box the way I had the floor. It made the run with the front edge secured with two carriage bolts, which I now undid so I could flip it over and make a nasty, gooey black mess. I have found that cutting the roof patch with paint thinner makes it a lot easier to soak into wood...and skin...and brand new leather seats - not sure how I'm gonna 'splain that one when she notices it.

I'm certain that any long term benefits gained by wearing a respirator in the previous step were promptly undone by my impromptu arm-bath in straight paint thinner to get rid of the offending stain (Out, damned spot. Out I say!). I'm a mechanic and see nothing wrong with being covered in grease, dirty oil, or anything else rolling around in the bilge of a boat, but a let a few drops of paint hit my skin and I cry like a little girl.

I got the box gooped up and after it dried I flipped it over and put the bolts back in. The back edges and top are going to get glassed so they blend into the front and side walls, so another glass job was ready to go.

We use steel drums for blocking up boats and, with so many boats going back into the water, they're everywhere as we haven't had a chance to tidy up yet. It looks a bit like all those boulders left behind by glaciers where they don't belong. I grabbed one and rolled it over because the next job to do was on the roof. Well, I tried to but wouldn't you know it, it was half full of water. I knocked it over to drain, selected another candidate, and dragged it over to the trailer. It looked fine from the outside but when I stood on it the rusted-out top started to cave in, giving me a premonition of myself stuck in a leg-hold trap...so into the scrap bin for that one.

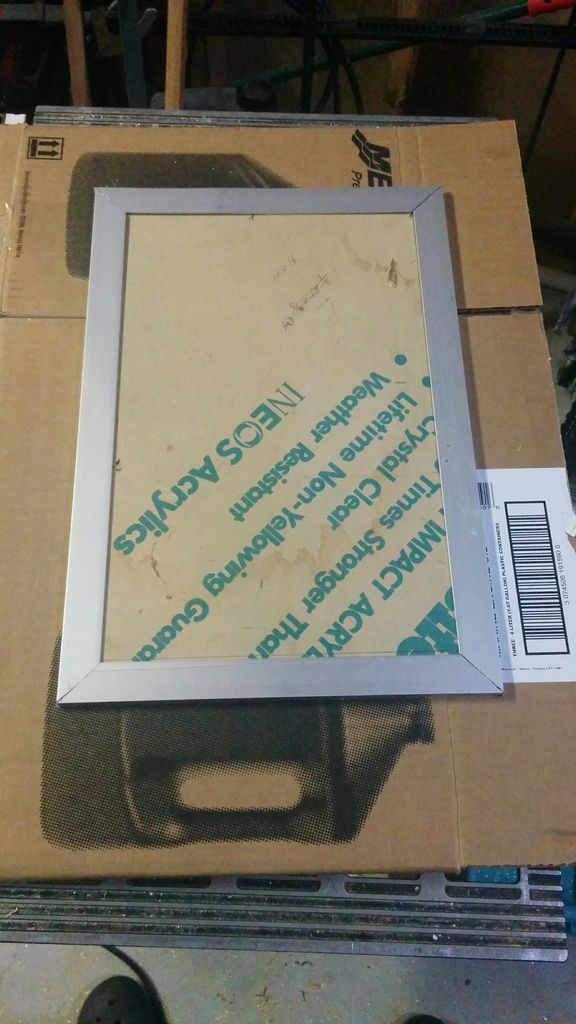

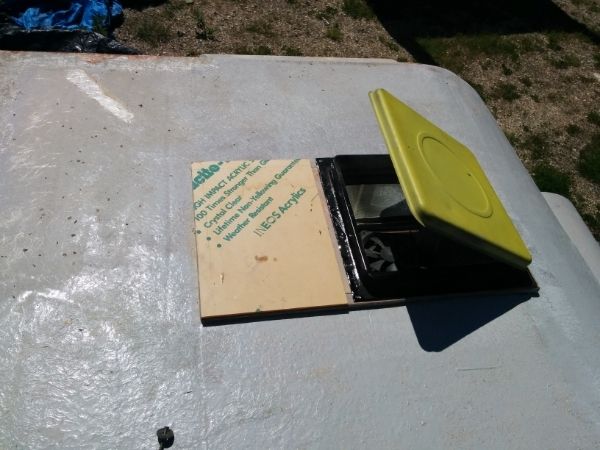

Third time's the charm - I got up to where I could work on the roof and pulled off the scrap of 1/8" ply I had pinned over the hatch/skylight opening. I pulled out the remaining pins and ground/sanded away the excess glass from the inside edge. I mixed up some resin with some cab-o-sil to make a thick resin-based glue lovingly referred to in the industry as bearsh*t. I glued down the curbing I had previously made up from 1/2" ply to keep any standing water on the roof out of contact with the hatch/skylight fasteners. The screws will be heavily bedded in sealant but the first rule with any sealant is not to rely on it !

The next job was to cover it in strips of glass so that the roof glass would effectively run up and over it, so now that too was ready to go.

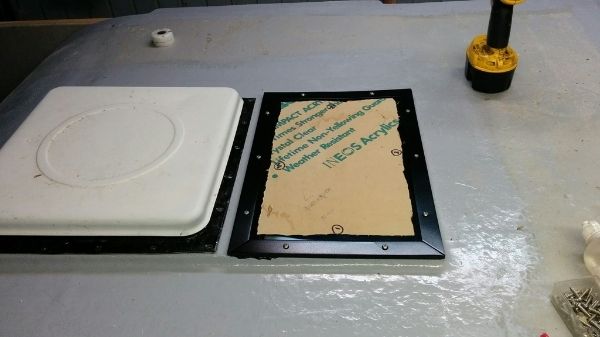

Curbing glued down (not glassed yet):

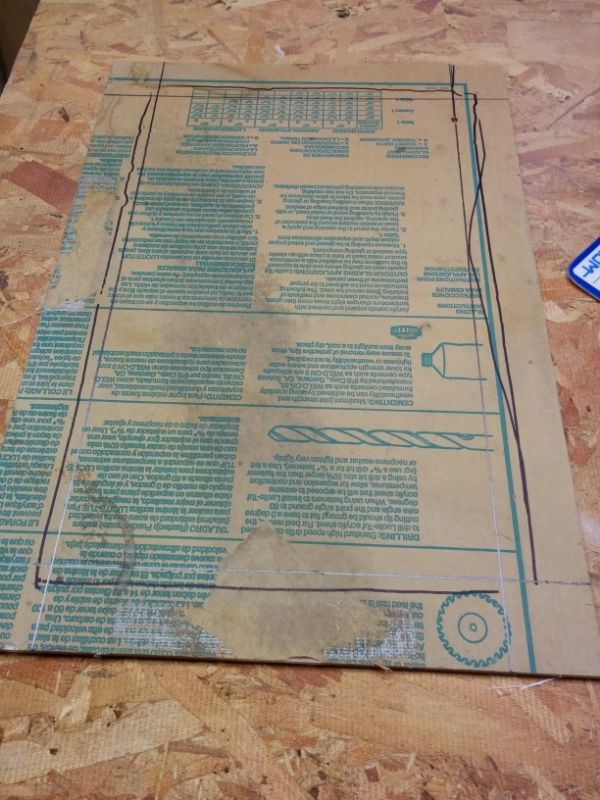

Cab-O-Sil texture:

Not longer after I realized I'd forgotten my electrical stuff, the sky clouded over...and my mood with it. I wrapped the trailer back up and put it to bed for another week.

).

).