Glenn,

There's always tradeoffs... if you were a scientist and could invent the perfect material, what would it be?

just for fun, here's a couple of my thoughts...

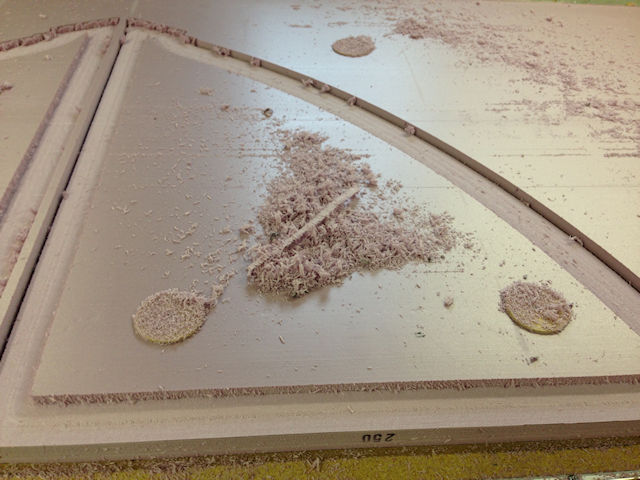

no wood, all those capillaries are so destructive

foam, while nice and light, has no density to speak of

aluminum has a nice density, but gets heavy fast

what if we combine foam molecules with aluminum molecules?

oh wait, there's also plastic

home depot sells a shed that is strong, light and plastic, but it"s not glueable

what if you combine wood molecules with plastic molecucles?

how about aluminum molecules and plastic molecucles? okay, that's my pick!!! Lets call it aluplastic

I'll bet you like alufoam better!!!

Lets design a teardrop around this stuff!!!

Mike

GPW wrote:Coroplast would be fine if it held a screw , and had some real strength ,glued easily , didn’t decompose in the Sun in 5 years ... Maybe a thicker wall material ..

OSB , (the waterproof kind) seems to be a better choice for

some things trailer (although it is very

HEAVY ) and cheaper too .. And not that cheap -arse stuff they make RV floors out of ... One whiff of moisture , it turns to oatmeal ... We found we could even save that “stuff” (G. Carlin) with the mix , it soaked in the mix like a sponge ... once saturated , wouldn’t take any more ....Done !!! Mix worked a treat keeping water out and oatmeal contained ..

Figure if it can waterproof plain cardboard then what else ...

Figure if it can waterproof plain cardboard then what else ...

Figure if it can waterproof plain cardboard then what else ...