Page 1 of 2

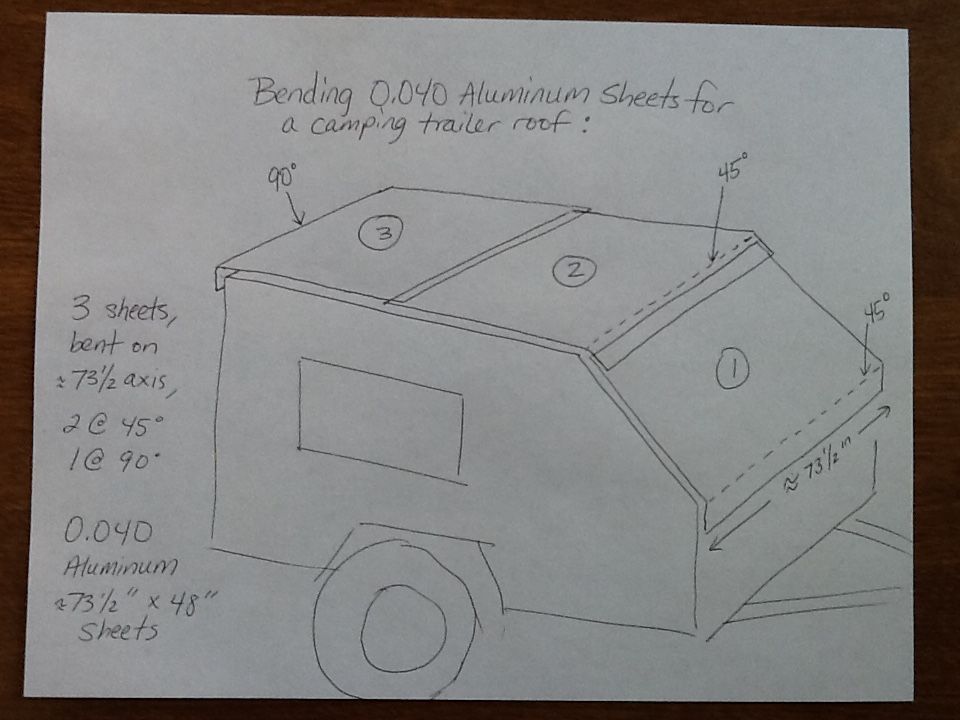

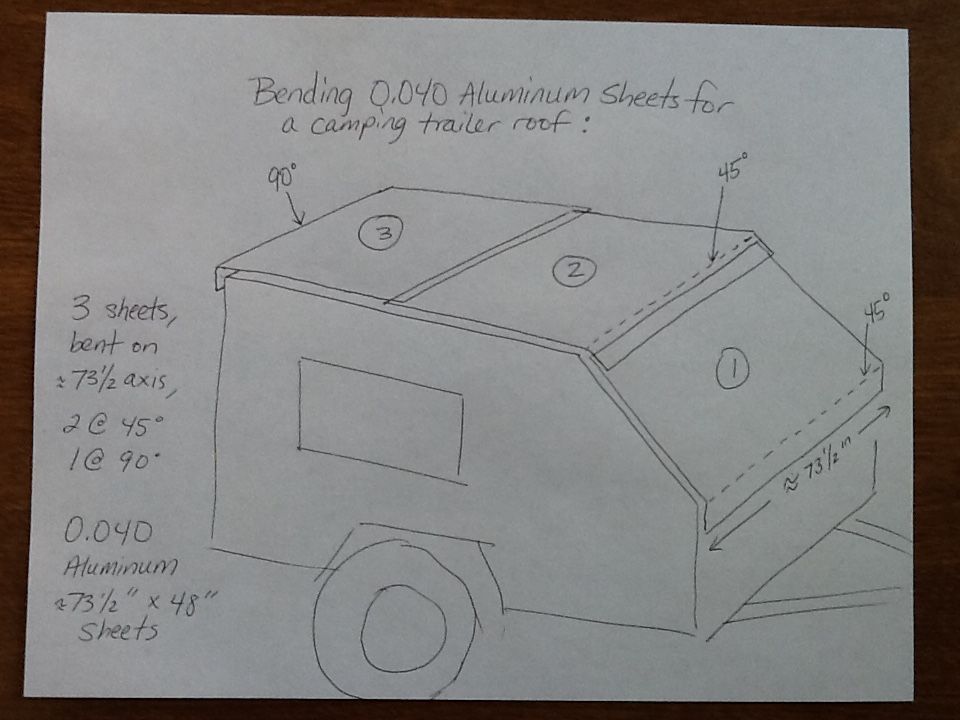

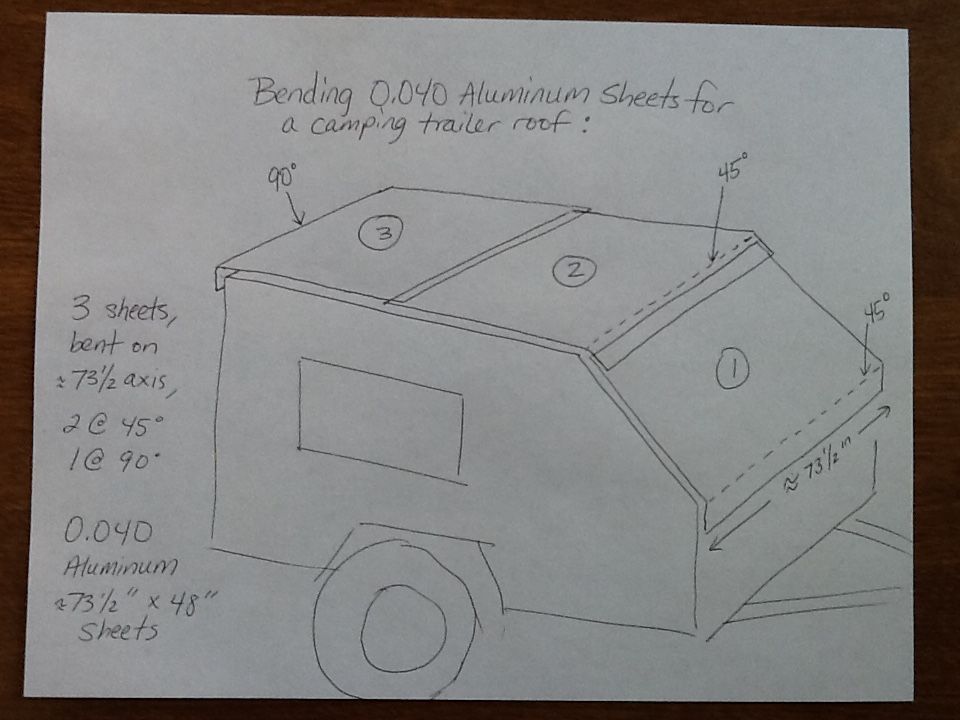

Bending 0.040 aluminum sheets

Posted:

Tue Apr 12, 2016 3:00 pmby lfhoward

I need to bend three sheets of 0.040 aluminum to make the roof for my rectangular camping trailer. The roofing brake I borrowed from a neighbor was not beefy enough to bend the sheets I have, because they are thicker than aluminum roofing material. So I called around to machine shops in the area to get an estimate for how much it would cost to make these three bends. Anyone want to guess how much I was quoted?

Here is a photo of the build so you can see it to scale.

$50 a bend, for $150 total, plus tax. Does this sound crazy to anyone else? It's only 2 minutes in the bending machine for each bend. What is a reasonable price for this work? I am going to continue to call metal shops, in hope of getting a lower price quote.

In the meantime, does anyone have any suggestions for bending these sheets myself? I tried a rubber mallet on a piece of scrap and it doesn't look good at all. I can see how it would be easier to install sheet metal over a curved roof than a flat one like mine. Maybe I'll make my next build more aerodynamic. Thanks for your suggestions!

Re: Bending 0.040 aluminum sheets

Posted:

Tue Apr 12, 2016 3:12 pmby dales133

Should be able to get it done less than that.

I know its more expensive here and 80 -100 bucks an hour is about the norm for fabrication here

Sent from my SM-N910G using Tapatalk

Re: Bending 0.040 aluminum sheets

Posted:

Tue Apr 12, 2016 3:22 pmby lfhoward

dales133 wrote:Should be able to get it done less than that.

I know its more expensive here and 80 -100 bucks an hour is about the norm for fabrication here

Sent from my SM-N910G using Tapatalk

Where are you located? I am not far from Trenton NJ and Philly, PA so the hourly rate is probably high here.

Re: Bending 0.040 aluminum sheets

Posted:

Tue Apr 12, 2016 3:22 pmby dales133

Australia

Sent from my SM-N910G using Tapatalk

Re: Bending 0.040 aluminum sheets

Posted:

Tue Apr 12, 2016 5:05 pmby halfdome, Danny

If you don't have the proper equipment that the shops spend good money on then $50 a bend would sound reasonable to me.

Years ago I wouldn't even turn on my table saw for less than $100.

A lot of builders seem to go the route you've chosen for the perceived ease of construction, whereas a radius front teardrop is so much easier to build and you don't run into this situation.

Good luck, and just pay the man.

Danny

Danny

Re: Bending 0.040 aluminum sheets

Posted:

Tue Apr 12, 2016 5:31 pmby aggie79

Why do the 90 degree bend? I would just use aluminum angle or whatever trim you plan for the sidewall/roof junction. This would lower your price to $100. Seems like a fair price to me if you add in what the equipment costs, operator expense, overhead (accounting, insurance, etc.) and profit.

Re: Bending 0.040 aluminum sheets

Posted:

Tue Apr 12, 2016 7:10 pmby dogscats

Call where you got the alu.See if they can bend it for you Around here if you got the Alu. from them it cost around $ 5.00. per bend .If not clamp down . Start to work with 2 x 4 do with junk piece first .Will need two to do it. First how hard is the alum.

Re: Bending 0.040 aluminum sheets

Posted:

Tue Apr 12, 2016 11:37 pmby Redneck Teepee

Labor rate, insurance rate, workman's comp rate, rent, wear and tear on the equipment, and the list goes on.....and don't forget profit, or the tax on the profit, yep the guy with all the money invested in his equipment, that you need to make your bends wants to make a profit. $150 is not outrageous at all.

Re: Bending 0.040 aluminum sheets

Posted:

Wed Apr 13, 2016 7:08 amby lfhoward

You all make good points that owning a business with big machines and paying your people is not cheap. Maybe I need to adjust my expectations about what I am willing to pay to get this done right. Thank you for all your feedback, everyone!

Re: Bending 0.040 aluminum sheets

Posted:

Wed Apr 13, 2016 7:29 amby dales133

You should be able to find someone that will do it on an hourly rate.

It wouldnt take long and you could pay them a full hour then its win win.

Sent from my SM-N910G using Tapatalk

Re: Bending 0.040 aluminum sheets

Posted:

Wed Apr 13, 2016 9:22 pmby elcam84

It's priced high not because of overhead etc but because they don't want to do it. Small jobs like that are more of an annoyance for shops.

Re: Bending 0.040 aluminum sheets

Posted:

Wed Apr 20, 2016 11:33 amby JaggedEdges

Is forced air heating and air conditioning common there?

Reason I ask is because it's practically the default in north america and there are many small HVAC outfits, who form metal for ductwork. There's one down the street from me with a metal brake, and I'd just kinda wander in and ask. I've had things like that done for "beer money" cash pricing before.

Re: Bending 0.040 aluminum sheets

Posted:

Wed Apr 20, 2016 12:17 pmby JaggedEdges

Okay, had a quick think about what I'd do to do it on my own, I think I'd use the weight of a car and "scrap" lumber to press them into shape... basic idea would be that you use 2 jacks to put car weight on a 4x4 that's pressing the metal down against another 4x4 underneath it. BUT panel, lower 4x4 have to be constrained from moving, and the top 4x4 has to be chained or have a strut bolted into the ends of the lower 4x4 so it can't move horizontally. Also a brace might be necessary in the middle to stop bowing. Though you could also constrain movement by say 4 2x4 braces to the bottom ledge/stop that the panel is resting against. I think you'd wanna do this on a piece of thick OSB or scrappy ply to nail everything down to.

This is not a fully developed idea, there's a lot of detail and safety precautions that need to be thought through in situ. If it's scaring you already, don't do it, if you're going "yeah, yeah, and this, and that" then rely on own experience to carry it through.

In general, when I've needed a lot of force or weight, I've used a vehicle as a tool, if that's not enough I've used a 10 ton jack against a beam in the basement, if I've needed immovable objects to exert extreme force against, I've use a large tree or the house.

Re: Bending 0.040 aluminum sheets

Posted:

Wed Apr 20, 2016 6:51 pmby Redneck Teepee

JaggedEdges wrote:Okay, had a quick think about what I'd do to do it on my own, I think I'd use the weight of a car and "scrap" lumber to press them into shape... basic idea would be that you use 2 jacks to put car weight on a 4x4 that's pressing the metal down against another 4x4 underneath it. BUT panel, lower 4x4 have to be constrained from moving, and the top 4x4 has to be chained or have a strut bolted into the ends of the lower 4x4 so it can't move horizontally. Also a brace might be necessary in the middle to stop bowing. Though you could also constrain movement by say 4 2x4 braces to the bottom ledge/stop that the panel is resting against. I think you'd wanna do this on a piece of thick OSB or scrappy ply to nail everything down to.

This is not a fully developed idea, there's a lot of detail and safety precautions that need to be thought through in situ. If it's scaring you already, don't do it, if you're going "yeah, yeah, and this, and that" then rely on own experience to carry it through.

In general, when I've needed a lot of force or weight, I've used a vehicle as a tool, if that's not enough I've used a 10 ton jack against a beam in the basement, if I've needed immovable objects to exert extreme force against, I've use a large tree or the house.

Whiskey-Tango-Foxtrot

There is a difference between just bending the metal without any accuracy and forming/breaking it properly.

Re: Bending 0.040 aluminum sheets

Posted:

Thu Apr 21, 2016 6:53 pmby JaggedEdges

Nah you'd get it within about plus or minus eighth of an inch with careful setup, I assumed that wouldn't be a problem given the illustrated overlaps. It's basically a brake formed by the 2 (best) edges of the 4x4s, at length set by a stop nailed down to your base, using brute force instead of leverage.

Danny

Danny