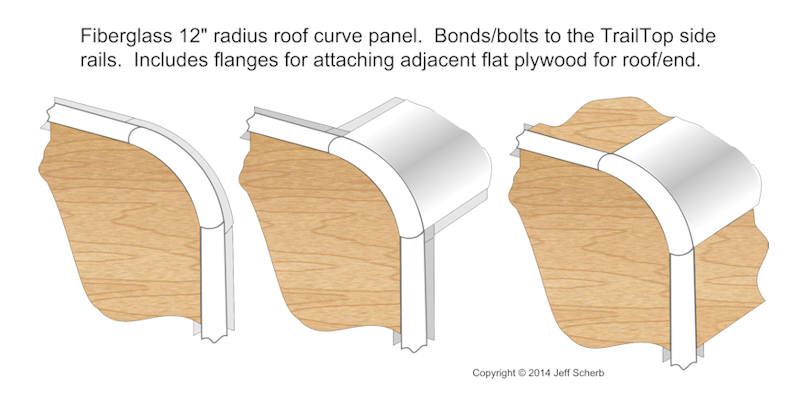

I'm not convinced that insulating or foamie construction would require a different offset to the flange. If you skinned with 1/8 or 1/4" ply, then just bond your chosen foam to the inside. You could do the same with two layers of foam easily enough. Then skin over with either canvas or glass. This is a great idea.

Now if a different offset were used, you could just edge groove the foam and insert the flange. But I don't think it would be necessary.

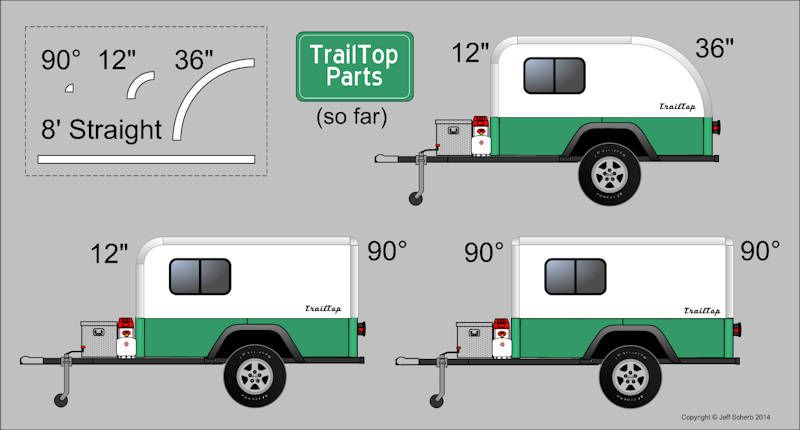

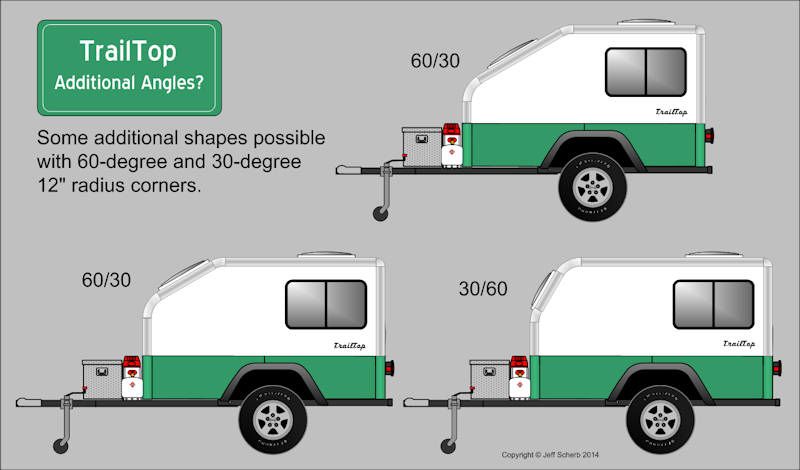

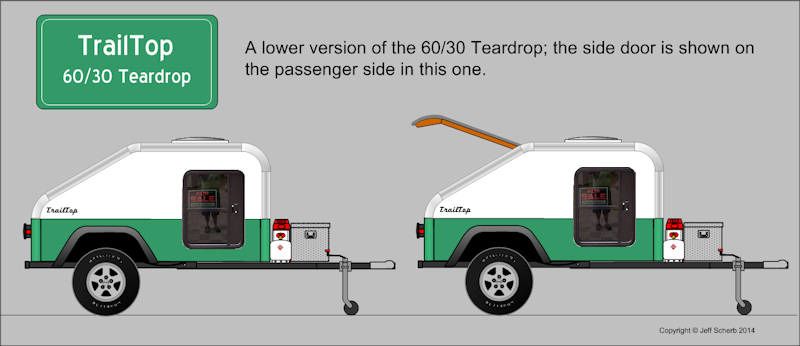

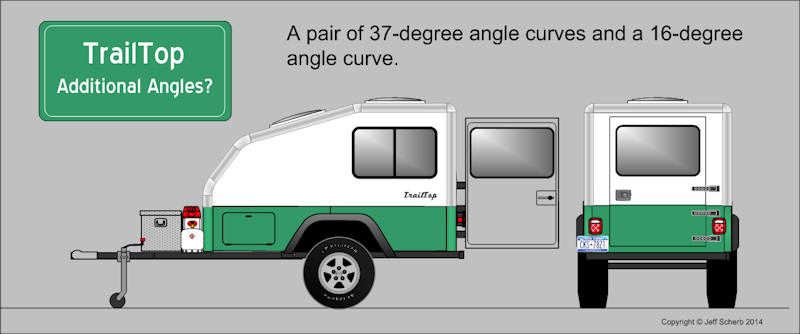

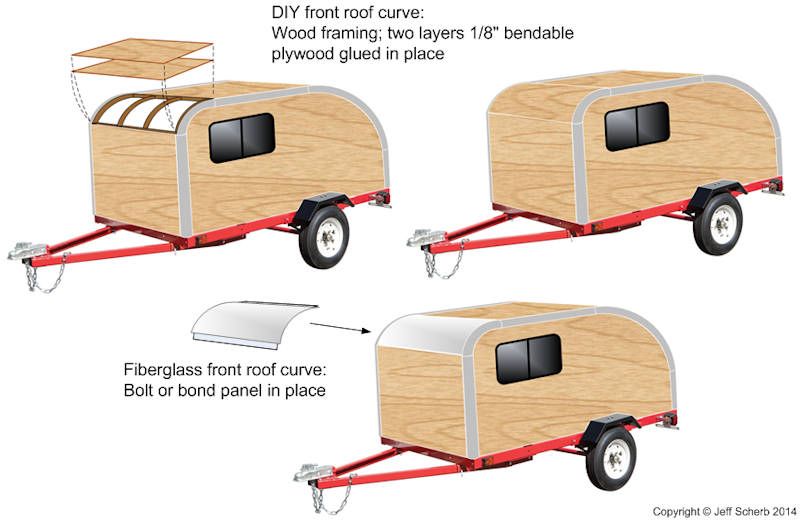

"TrailTop" modular trailer building components

-

wagondude - 1000 Club

- Posts: 1535

- Images: 35

- Joined: Sun Jan 16, 2011 7:41 pm

- Location: Land of the Jayhawks

Re: "TrailTop" modular trailer building components

mikerueve wrote:I'm with Grant on this one. This looks like something that would make a great starting point for a novice.

I am one of those people who have very limited wood-working skills and felt so intimidated by the building and

assembly process that we are having one built as we speak. I think that if there had been a "kit" like this available, that I might have seriously considered taking a chance.

I love the idea of having one that I built myself, but have to realize my limitations. That and the fact that we would like to start camping again sometime this decade. I will be watching this thread with MUCH interest.

Mike,

Thanks for the comments. Please keep and eye on me throughout this design process - if there's something I've done or a way I've designed something that you think makes assembly too difficult for a novice, please let me know so I can reconsider that area.

And the more experienced builders please keep an eye on me as well, I don't want the TrailTop concept limited to novice builders, I want it to be a great starting point for showpiece campers as well, so if there's a feature or something you think should be done differently or added for more advance use, please let me know and I'll do my best to make sure everything is possible.

Jeff

- jscherb

- The 300 Club

- Posts: 388

- Joined: Sat Dec 24, 2011 8:27 am

- Location: Elmira, NY

... maybe not such a good idea, sometimes ...

... maybe not such a good idea, sometimes ...