Now, I have tried to read as much as I can since monday but I am brand new to all this. Problem is I need to have this built by the end of summer, preferably by the middle of September to test behind the tow vehicle while its still warm. If its not done by then it absolutely has to be finished by the middle of october. I was originally planning to start building a rough mock-up out of cheap osb next week to test out different front and rear designs for aerodynamics, finalize the design by June 22 and have all my materials sourced and bought by the end of the month. Thats probably not going to happen now, but I have a short timeline for doing something I have never done before. I have no garage or indoor place to work in at home and I will be working on the tow vehicle and buying supplies for the trip in the winter. The car will be recieving many modifications and upgrades to prepare it for this trip. We are doing a test run with the trailer, car and all supplies may long weekend next year, making any changes we need to and then leaving leaving middle of June.

Anyhow, I can describe the trip and tow vehicle more later, I need to get the trailer planned now and I am hoping for some help. I will quickly outline my old plan, and why I was going to do what I was, then describe what I am hoping to build instead.

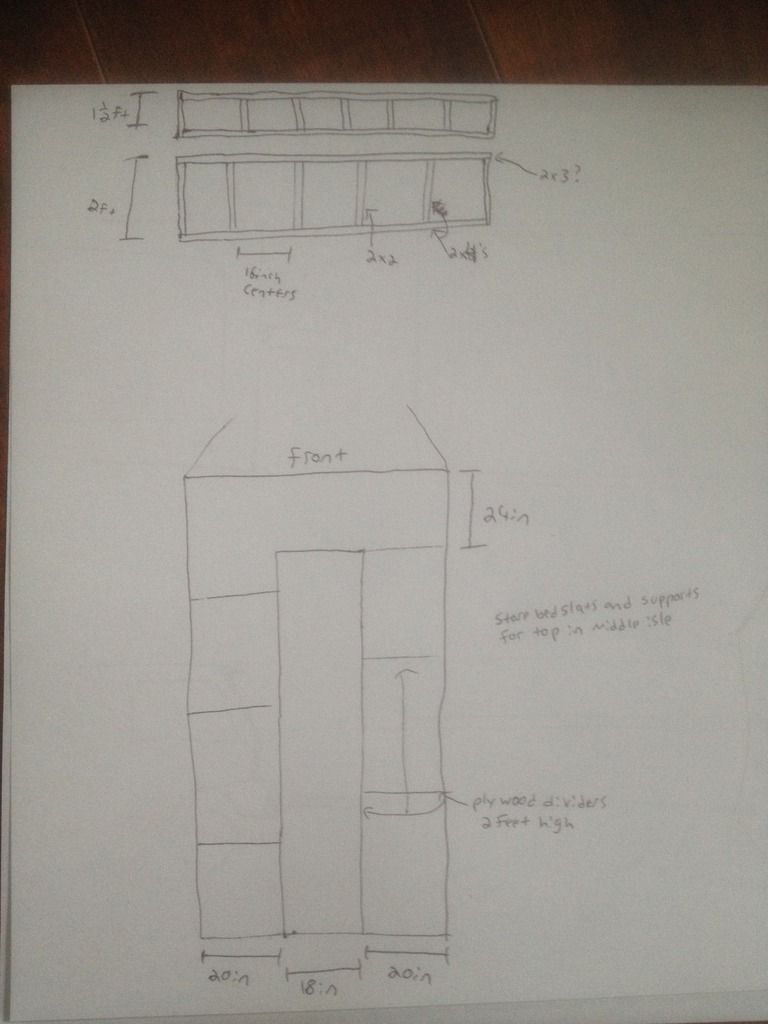

I decided on a 5 foot wide trailer because the TV rear bumper is 5 feet wide. Kind of keeps the wind drag down a bit and I won't have to think so hard about where the trailer is while driving and sightseeing. Looked at 8 foot long ones and liked them for their size and weight. Then looked at it more and realized that there isn't enough room for 2 kids to sleep in there with us or enough room for what we want to bring. So we have to go with 5x10. I had an idea to make a trailer where the roofline was even with the festiva roofline to cut down on wind drag and have it pop up quick from inside to use when stopped. My ideas for that was a lot of building, bit heavy, and takes time to set up and take down every time. Also less storage space. So I rented a covered u-haul trailer that was 8ft long, 5 feet wide and 5ft high inside, 6ft6in high from ground to roof. I did that to see how the festiva (my TV) would pull a covered trailer, as there is a lot of wind drag. Most covered trailers are taller than that though, so this has less drag than what I would end up buying- However most regular trailers are lighter than the u-haul. The 5x8x 6.5 tall inside dimension ones i looked at were 800 pounds and this shorter u-haul is 900 pounds empty.

I picked it up with my 2002 honda civic, The civic hated it. Once home I parked it and hooked up the Festiva thinking there is no way this is going to work. I filled my festiva up with weight, 5 gallon jugs of water, a transmission, all sorts of tools, steel rims... and hooked up the 900 pound trailer. To my suprise the festiva pulled it almost as well as the civic! I was shocked, the civic has 115 hp, almost double my festiva, yet the Festiva pulled almost as well. Then I got my bigger suprise, I believe it stops the trailer faster than the civic! At the very least just as fast. And i have all brand new drums, rotors, pads and shoes on the civic. Couldn't believe it... Both cars were quite stable if i jerked the wheel around or swerved at 60mph. I drove quite a ways to find some big hills, 4th gear is adequite up most, keeps it above 52-54mph, but on the steepest ones it runs out of steam pretty quick in 4th. If i shift into 3rd at 50mph I could still speed up up any hill I found, even if just slightly, I was still speeding up. I went a couple hundred kilometers, then brought it back to u-haul with my festiva, did 70mph on the freeway no problem.

So, the festiva normally gets me 50mpg at those temperatures (52-54 in summer) and it dropped to 30.25mpg with the u-haul. Thats pretty good considering I had it floored most of the time in 5th and had it in 4th and 3rd a lot just doing the biggest hills we have within an hour radius around here. That is a 40% drop in fuel milage. My civic however only towed it home on the flat and it normally gets 44mpg and that dropped to about 21.5mpg, a 50% drop! I may as well drive a pickup with an extended bed for that kind of fuel milage... Anyway, I also took my 4x6 trailer with short sides and loaded it up with about 900 pounds total. Then i put a piece of plywood on the front that was 5 feet wide and as high as the roofline of the festiva. It was harder to tow than the u-haul, I got 29.6mpg with it after several hundred km. On the way home with it I pulled over and removed the plywood from the front of the trailer. After that it was still noticable that I had the trailer to speed up and slow down but cruising was exactly the same as with no trailer, exact same reading on the vaccum gauge as empty driving to work. So all that was slowing me down before was wind drag, just a piece of wood sticking up like that is worse than a long box.

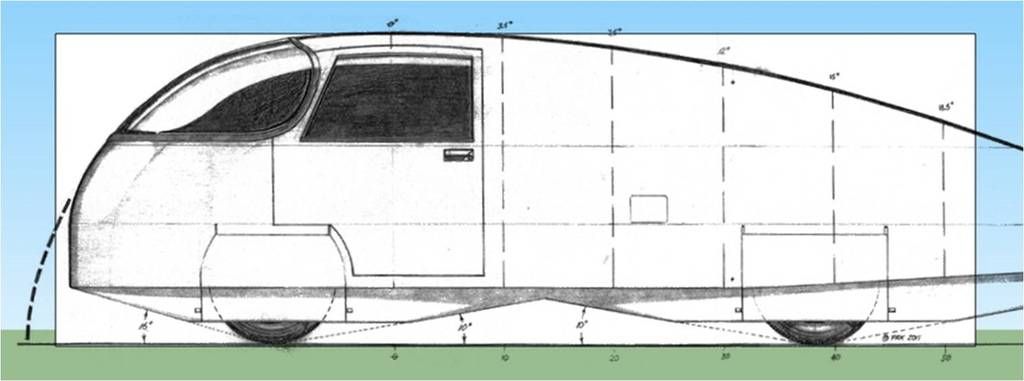

I read some about trailer aerodynamics, looked at how to build them better a bit and decided we had to go with a shorter in hight trailer, it will be way easier on the car and myself while driving on this trip. Also at 30mpg and fuel at $1.15/L its $3400 on gas. If I get it up to 40mpg that saves me $900-1000 in fuel as well as being easier on the car and my attention, noise level is lower with less time spent in 4th and 3rd gear... I could pull a full size enclosed 5x10 but I dont think i want to. It would be so nice for no set up or take down time, but I dont think that outweighs the disadvantage of drivability. Also it would catch more crosswind.

So I had been looking at trailers back in december and they were fairly plentiful and cheap. Now there are not very many and they are pretty pricey. Not many people selling them for much less than new price and I want one that is as light as possible, there are lots of heavy ones out there.

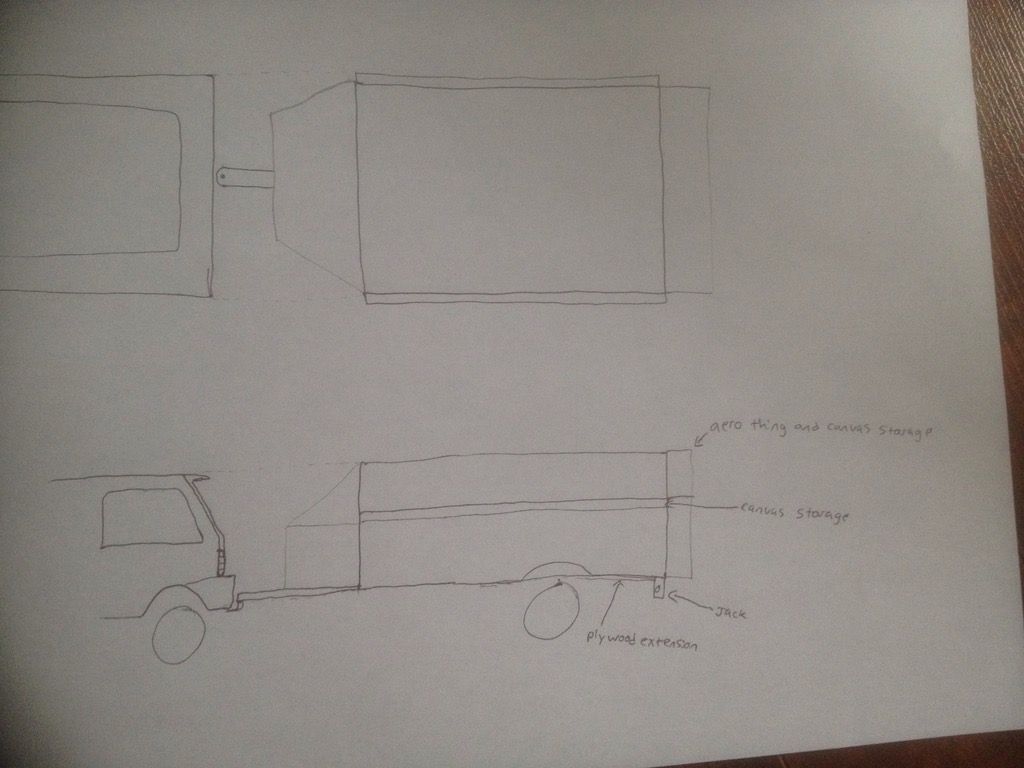

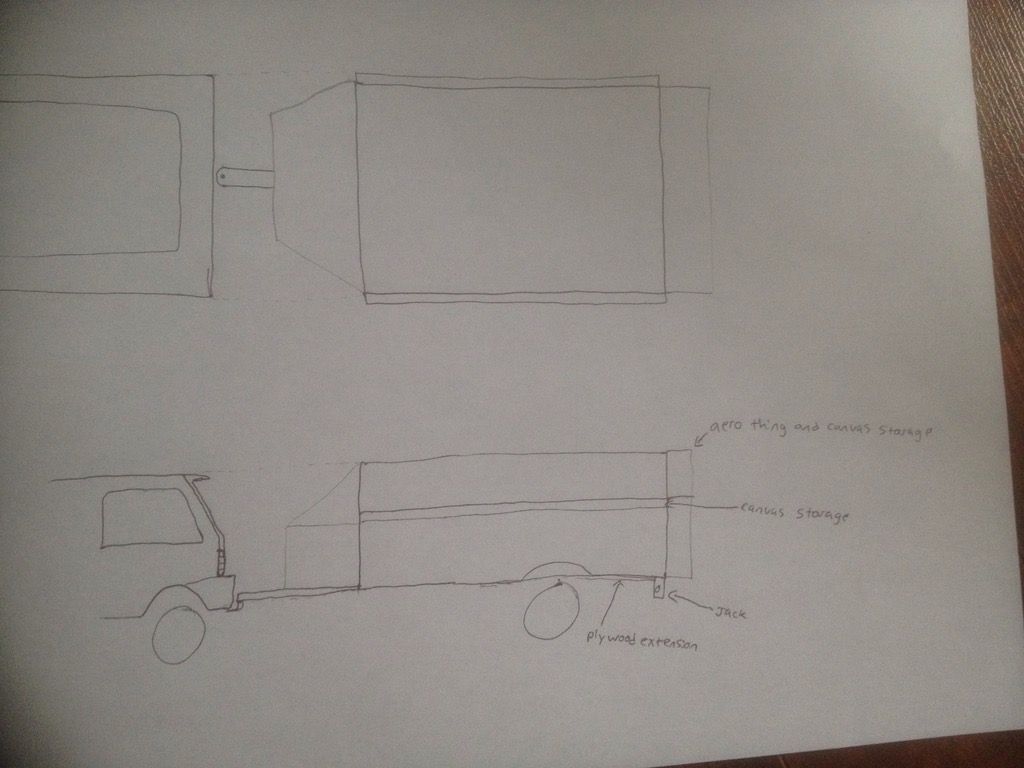

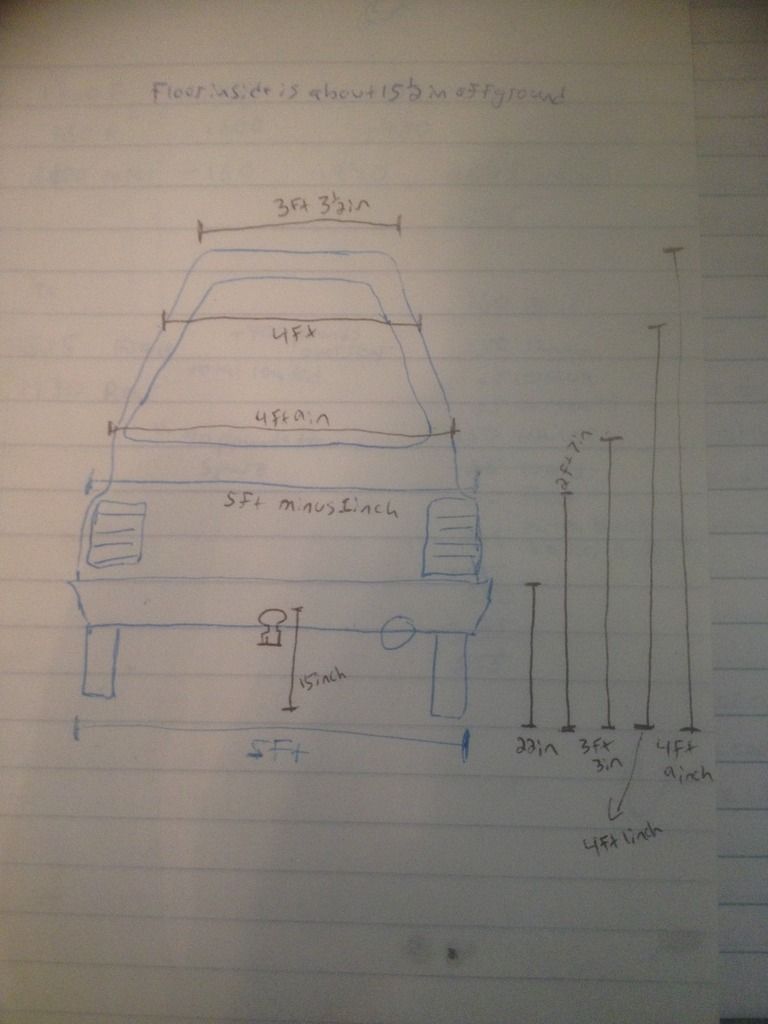

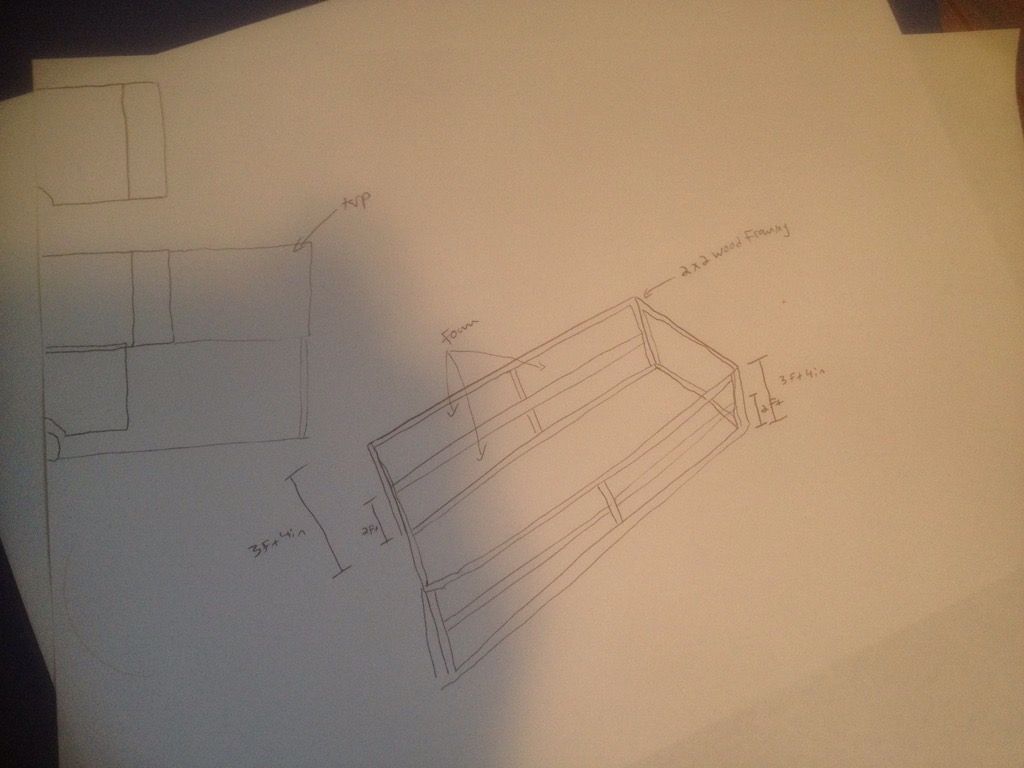

I bought a new lightweight 5x10 trailer. I was going to build sides on it that are 3ft 6 in high with a split at 2 ft up the side so there is 2ft on the bottom half and 1.5ft on the top half. I want the roof of the trailer to be even with the roof of the car while lowered. Then I wanted to be able to lift up the top section and stick kind of legs in there so That we can stand up in it. I think I am 5ft10 and my wife is 6ft, so they would have to be about 2ft 6ish tall. Then I was going to have had some type of canvas attached to between the top and bottom halves that would fold up into a little shelf thing on the outside of the trailer when its lowered. On the inside I will have a 20.5inch space down the length of each side for storage, 2 feet at the front. That leaves 18 inches in the middle for walking. I would put plywood 2 feet high to divide the storage areas to keep everything neat. Then have 5 ft long 1x4 bed slats that could be stored somewhere while towing, but to sleep would lay overtop of plywood storage divider sides and we could inflate the air mattress on top of it. On the front of the trailer I will build something for better aerodynamics and it will house the spare tire for car and trailer, battery and probably the showering unit. A cubby near the axle only accessible from the outside and airtight to the inside for storing the propane and a gerry can of gas. I want to weld some kind of jacks to the back of the trailer for leveling so it doesn't rock much while sleeping at night. I planned to frame it with 2x2's and use probably 1/4in plywood on the outside. Then glue 1/16th thick plastic to the outside for protection and waterproofing. I can get 4x8 sheets for $15 I think.

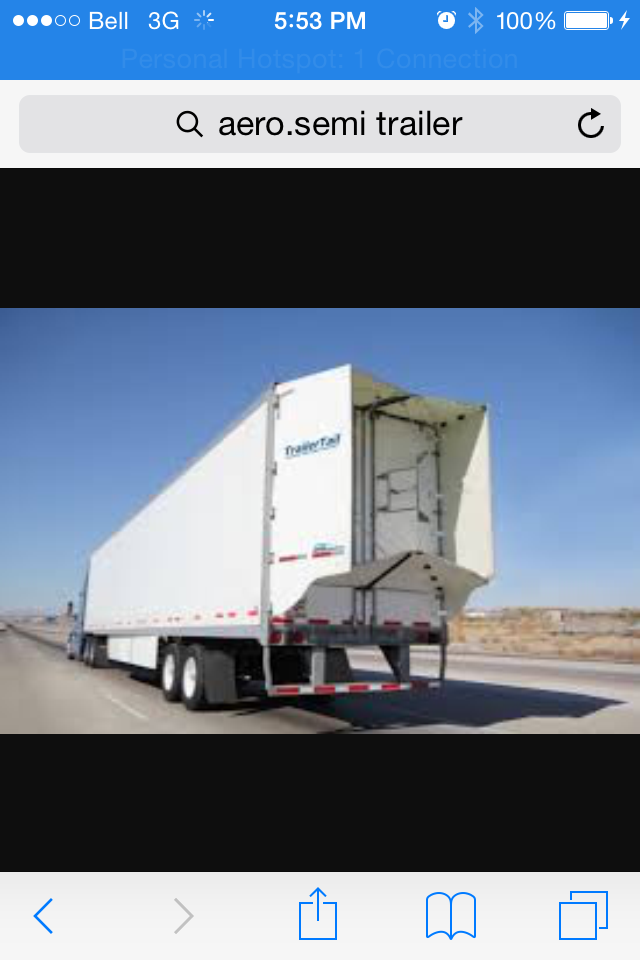

I havent figured out to well what I will do on the back of the trailer. For aerodynamics you kind of extend the sides past the actual back of the trailer, reduces drag a lot. I can do that then attach some type of screen or canvas tent-like stuff to the inside of it to extend our bug and rain free trailer useage area. I also need to bring our bikes somehow, thought of attaching the bike rack to a receiver i could build in the back of the trailer, then moving it to another receiver on the side of the trailer when parked but then if its raining when we stop thats a pain to move. I really dont know where to put the bikes yet.

Inside the trailer we need to store all our cooking gear, stove, utensils, pots, toaster and all that. We need at least 2 coolers to store food, one if not both will be powered. Water for drinking as well as jugs to hold shower water. Diapers for the kids

Clothes for all of us, enough for a week including warm clothes, raingear... (temperatures can range from 32f to 105f, snow, rain, sun wind and bugs over these 3 months where we are travelling). Inflatable boat, motor, lifejackets and paddles. 25 pound Propane, 20 litre gerry can of gasoline. Air matress, sheets, matress topper, pillows, kids matresses, electric air pump. Folding chairs, kids toys, towels and soap for showering. Thats a fair bit of stuff...

Clothes for all of us, enough for a week including warm clothes, raingear... (temperatures can range from 32f to 105f, snow, rain, sun wind and bugs over these 3 months where we are travelling). Inflatable boat, motor, lifejackets and paddles. 25 pound Propane, 20 litre gerry can of gasoline. Air matress, sheets, matress topper, pillows, kids matresses, electric air pump. Folding chairs, kids toys, towels and soap for showering. Thats a fair bit of stuff...I am planning to run wires with dc power from my car battery to the battery in the trailer. Then have some dc outlets in the trailer for chargers, electric air pump, powered coolers and stuff. I will keep all the lights in the trailer 12volts. I will also run 120v ac power from the inverter in the car to the trailer and probably just have one outlet for whatever we might need in there.

I weighed a whole bunch of stuff, and that plan for the trailer build came to about 970 pounds, then everything I want to put in it is about 900 pounds. I need to keep the trailer to 1700 pounds max so I was trying to come up with what I could all take out when I found out about foam trailers. Building this with foam should allow the trailer build to be lighter and be more convenient than my canvas idea.

On the front I want to do something to connect the car to the trailer and get rid of the car-trailer gap. Havent figured that out yet.

I have no idea how I will do the rear door since this thing splits in half.

Old trailer plan:

Profile of back of Tow vehicle

Uhaul

New trailer I am using for the build

I want to test out this type of design on the rear and see what it does

Then between the car and trailer I want to block the gap something like this and do something similar on the wheel wells.

Anyhow, that was my plan. Now for the new plan. The trailer i bought is supposed to be 700 pounds. I haven't weighed the axles yet. The wood decking is 360 pounds if you calculate the weight of treated lumber for 50 square feet. Take 40 pounds off that for gaps and just to be safe and we have 320 pounds. I am cutting the ramp off for sure and probably the sides and I guess them to total 70 pounds. That leaves me with a 310 pound trailer. I was thinking exterior plywood on the floor, the wood glue and canvas over styrofoam for the sides and roof. A wood frame in it especially on the bottom to attach the dividers to and to have something to rest the top half on that is supportive enough. Then a front aero panel that will house the tires and stuff. The deck hight of the trailer is 14 inches, so that leaves me with 3ft 6in to work with for hight on the trailer. I do not know what I am doing for the door on the back. I will manually raise and lower the top section. I calculated the water we would need to bring for cooking, cleaning and drinking for 3 days. Its a lot. Also want to be able to fill another tank and go shower. Looking into water tanks for under the trailer. This is on a tighter budget.

I have a bunch of questions. I am reading as much as I can on this site, but need to get started real quick and hate to do things without a solid plan. If there are other builds I should read through or articles that answer my questions please attach them in this thread, I would appreciate it very much! I will start another thread about our trip plans if there is interest in that later.

So, my questions are:

-Will the foam be strong enough and will the trailer last 30,000km and 3 months of continuous use? I see people saying these trailers are strong but then are happy with how long they lasted when they leak after 5 years...

-Is foam and canvas optimal for what I want to do? That being light, cheap, durable enough. I have some equipment at work I will picture below that I can use to laminate other stuff.

-how do I seal the top part to the lower half to be bug proof when it is raised and we are sleeping?

-should I rest the top part on the trailer deck when its down or on the top of the lower half?

- Is there a completely different style of trailer that would work better for what I want?

- I want to close the car-trailer gap but have an aero front in case that breaks or fails. Suggestions? That spandex and velcro does not stretch enough to turn sharp. I saw thin plastic attached to the TV and on recessed spring rollers on the trailer suggested. My idea was spandex/canvas/tarp attached with velcro to the rear hatch of the TV and either good quality bungee cords keeping it taut to the trailer or spring rollers and cables. Any other suggestions?

-I am going to start looking through the section of the forum entitled 'skinning secrets', but is there one particular article that explains it well? like I said, I found this site 2 days ago...

-I am wide open to any design modification suggestions! As long as it fits in with this trip- 30,000km in 3 months behind a 63hp car with 2 adults, a 4yr old and a 2yr old.

-How strong does just plywood with minimal framing get when your do the glue and canvass? is that better?

Thanks!

At where I work we have a CNC router table. It is 7ftx12ft. The spoilboard on there now is just bigger than 4x8. Materiel is held down by that huge vaccum pump on the floor on the left. We cut a lot of custom sized shower floors with it. Quite similar to this actually. Cut the floor to any shape, size, slope you want and then cover each side with fibreglass so its strong enough to drive a truck over, drop it in and tile your shower.

Router

Also We do a bunch of vaccum forming.

Vaccum

I started doing a drawing then realized I have way more reserch to do, I dont know enough about foam trailers to make a drawing yet. Please help! :p

This is just of the lower half. Do I need a verticle in the middle of the 10ft length? The middle horizontal framing at the 2ft hight is to attach the dividers inside to.

Going to do some more reading now.

)

) But the car will be able to tow whatever trailer I make safely for the 30,000km. I have a plan for getting the car ready for a trailer under 1700 pounds.

But the car will be able to tow whatever trailer I make safely for the 30,000km. I have a plan for getting the car ready for a trailer under 1700 pounds.

)

)