Thanks for the warning Pete. No camber in this one. It's straight as an arrow. And my brother in law is a recently retired life long pipe fitter with awesome welding skills. I have no fears that this task will be a problem.

And as folks read through this build don't hesitate to bring up concerns. I'm confident about many of the build tasks, but, building with foam is all new to me. Especially the task of building the hatch out of mostly foam. Not sure about that, so chime in when you can.

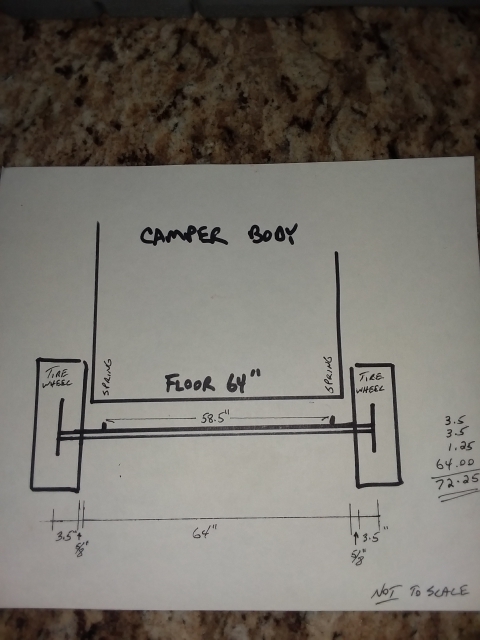

Edit... Began the axle extension. It went well. Was 68 1/4" hub face to hub face. Now 72 7/8" face to face. And no longer a need for spacers. I've allowed for 3/4" to 7/8" clearance tire to wall.

Calcs done

1" black iron (Sch 40) pipe is about .023 wider than the Uchannel in the axle. I ground down opposite sides of the pipe a little more than half that. The pipe will fill the void in the C channel from spindle to spindle.

Cut axle in half

Fit and futz

Fitted and ready for fire

Prime and paint

As Pete warned there may be some camber to the axle. Usually good quality trailer axles have camber built in. This is a NT trailer. Not saying it is not quality, but, no camber is designed into the axle for the light use they expect it to be used for. So, as I learned today, when welding, metal moves. An experienced welder knows how to limit the movement and/or use it to their advantage. My bro-in-law is one of those experienced welders. The result of his skilled craftsmanship is the hub faces as well as the axle are now slightly cambered. I am happy that as weight is added to the trailer the toed in tires will settle into a nice flat area across the tread. I don't expect too much more than 1200# ever being loaded on this trailer so the slight camber will be perfect.

Addressing the trailer quality... this is the 5x8 Northern Tool Aluminum trailer, Ultra Tow brand I think is the correct name. I'm impressed with everything about this trailer from its aluminum gauge to its design. The only shortcomings are the fender and the turn,brake, tail light frames. Those are junk. I wasn't intending to use either so not a problem. The only other thing I would like to warn folks about is the axle and hubs. For the purpose that this trailer is intended they are all of sufficient quality. The axle just proved to be short for our TD design. When I contacted NT about getting a longer replacement I was told that the hubs/bearings would not fit the longer axle. So, rather than spending $200+ on a new axle/hub set we choose the route described above (total outlay for the axle extension was $25 for a 10' length of 1" black iron).

Bearing set is available, 30205/P6 (

https://www.amazon.com/XiKe-Bearings-30205-30x52x10mm-Bearings/dp/B01H5QP9AC and other sources. NT has no info to share about race sizes : ( I'll share other bearing/race info as I receive it. Per NT... "The bearing size is 2.05" x 1.18x 0.39". The inside diameter is .98"."

Tim

Many things here are messed up, so, there's that!

Many things here are messed up, so, there's that! (pg 2 of my first build)

(pg 2 of my first build)