Man you come up with some head scratchers.

I knew what I would want to do but trying to describe it

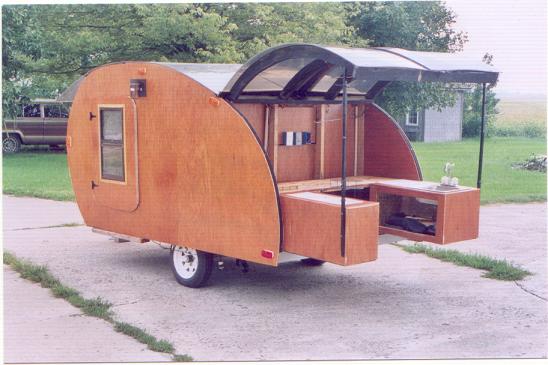

First here is my full radius hatch supports this is what the color drawing is trying to represent

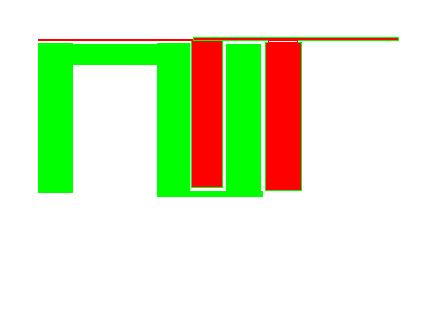

Now with a big curved 1x4 2x4 whatever.......

The green is the trailer side you frame this upside

down " U " just like a tear roof side attached to mini

spars and the curved final bow for the return

(just like above) now you fasten a under skin of

1/4 ply and another bow this forms the right side

up green "U" this will be fiberglassed and used

as the rain channel. The red is your hatch you

have an inner bow to strengthen your hatch

then the outer bow fits into the rain gutter being

hung by the outer hatch skin. The bottom of the

rain gutter should have a clear path to the outside

without interuption. Since you have essentially a 1/2

hatch ending at the counter some type of a catch cup

and drain tube will be needed to allow the water to

daylight out

Gasketing could be added but may prove unnecessary.