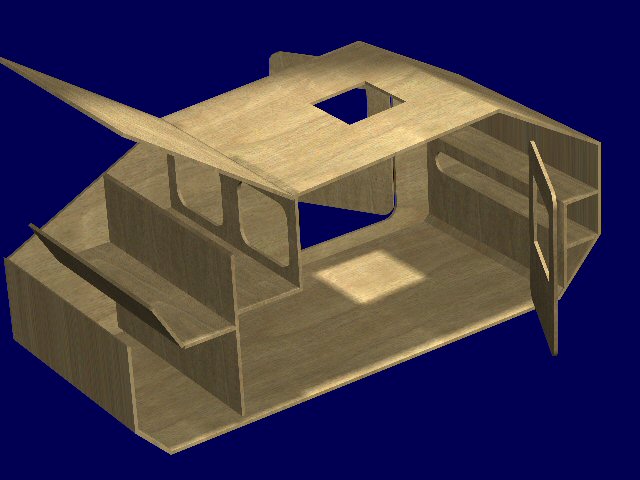

Definitely the hatch - it's still not quite right, though at least it doesn't leak. If I had it to do over I'd build the hatch first, then build the rest of the teardrop around it.

Joseph

Hardest part of building a tear?

41 posts

• Page 2 of 3 • 1, 2, 3

I agree with you Joseph. This is my second Tear and my last hatch. Next one gets side slide outs or something. Alan

Alan

-

ALAN GEDDES - 1000 Club

- Posts: 1637

- Images: 34

- Joined: Fri Apr 16, 2004 8:48 am

- Location: NC, Fayetteville

and i was born and raised in the south so i'm not up to date on all the yankee math.

and i was born and raised in the south so i'm not up to date on all the yankee math.