Hardryder56 wrote:Jeff,

Things are looking great. An idea for sewing: make up cloth side panels for the hatch area. With a drop down/slide floor extender along with side panels the rear of the trailer could be extended for addition sleeping/storage area when setting up camp. Check out the small tent campers you can tow behind a motorcycle for more ideas.

Tom

Tom,

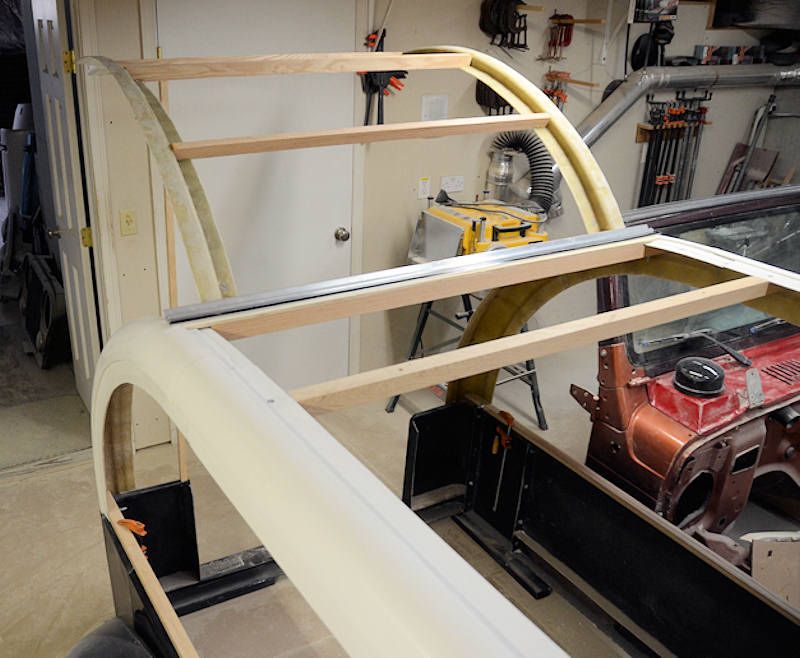

I was looking at a few examples of that idea the other day...

The one on the right only one side curtain installed for this photo. Interesting ideas.

...!

...! ...!

...! .

.

Wright

Wright