Very light and no wood at all -- possible?

62 posts

• Page 3 of 5 • 1, 2, 3, 4, 5

Re: Very light and no wood at all -- possible?

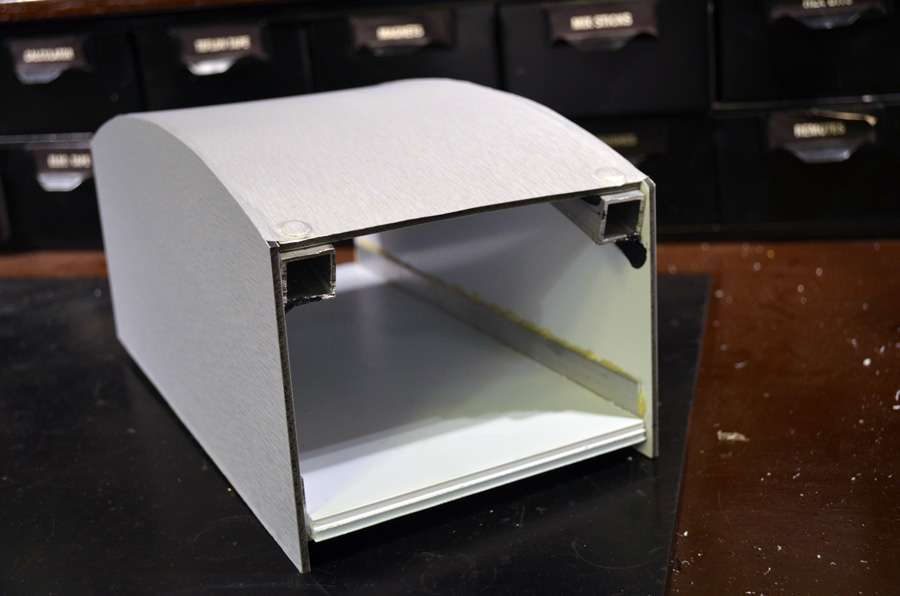

It seems like there should be a good way to control the amount dispensed in order to make the 3:1 or 4:1 expansion consistent and manageable. It's a shame they don't make a spray version. The construction adhesive doesn't expand. I don't know if that also means it's not polyurethane-based. It would definitely work for putting a layer of the corrugated plastic over the XPS foam for the interior. But for the bond between the aluminum composite panel and the XPS foam, I'd like a very strong bond -- since that would contribute a lot to the overall structural strength of the camper.

I was surprised by how well both Gorilla products worked on the corrugated plastic. I think the trick is to use plastic with the surface treatment already done. Another sample I have on hand has the more-slippery texture to it, which I suspect would resist just about any adhesive. (I'll test it to be sure, though.)

I've used Glidden Gripper with EPS foam and fiberglass cloth for another project, and it worked great. I also tested it as a foam adhesive, and it was great except when it had to fill gaps. I have no idea how it would work with the corrugated plastic, but since I've still got the better part of a gallon here, it will be easy to try out.

My biggest concern right now is finding the most effective way to bond the Aluminum Composite Panels to aluminum and to each other. That would take care of the main structural strength for the trailer.

I was surprised by how well both Gorilla products worked on the corrugated plastic. I think the trick is to use plastic with the surface treatment already done. Another sample I have on hand has the more-slippery texture to it, which I suspect would resist just about any adhesive. (I'll test it to be sure, though.)

I've used Glidden Gripper with EPS foam and fiberglass cloth for another project, and it worked great. I also tested it as a foam adhesive, and it was great except when it had to fill gaps. I have no idea how it would work with the corrugated plastic, but since I've still got the better part of a gallon here, it will be easy to try out.

My biggest concern right now is finding the most effective way to bond the Aluminum Composite Panels to aluminum and to each other. That would take care of the main structural strength for the trailer.

-

Jack Olsen - Teardrop Advisor

- Posts: 62

- Joined: Sun Jun 21, 2015 3:37 am

Re: Very light and no wood at all -- possible?

How about just riveting or screwing aluminum to aluminum joints for structural strength (you plan on aluminum angle for the outside corners right?) Maybe bed them in something like Sikkaflex 219?

Bonding foam and whatever you use for the interior surface wouldn't be so critical then.

Bonding foam and whatever you use for the interior surface wouldn't be so critical then.

- Pmullen503

- 1000 Club

- Posts: 1182

- Images: 67

- Joined: Sun Nov 23, 2014 1:33 pm

- Location: Fond du Lac, WI