SeaFlea wrote:Jeff,

I'd like to ask what may seem to be a "rookie question"... I am a rookie though so please bare with me.

Now that your proof-of-concept has proven this is indeed do-able, what becomes of the "project trailer"?

Do you sell it? Do you dismantle the "clam-shell" to re-use as the top for the "roof-top tent"?

If you were to sell it, do you have any idea what the dollar figure might be?

This is purely academic because the dear wife has already informed me that a trailer will not grace our driveway...

I'm just curious is all... If the question is inappropriate please let me know so I don't repeat the error in the future.

Great thread by the way. Love the tilt-top.

Charlie

Charlie,

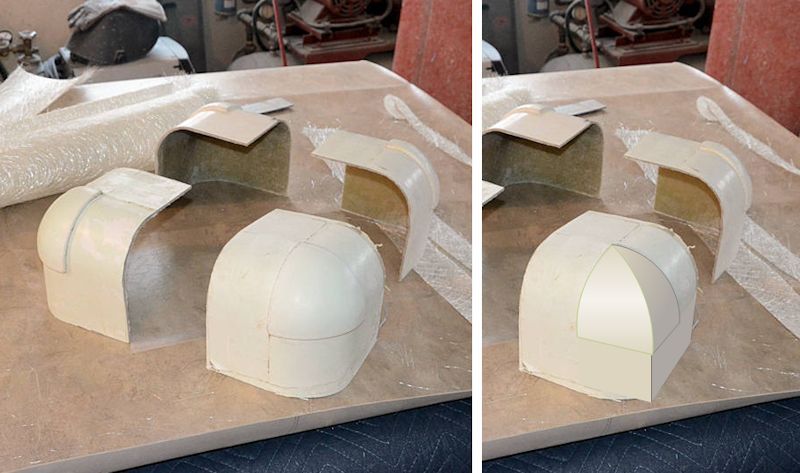

It's a fine question. I do most of my projects mostly because I enjoy the challenge of designing. Sometimes the goal is something I plan to use myself, like the Safari Cab hardtop and the CJ Grille Kit on my black Jeep that I showed the other day. But lots of times the project is just about the design challenge for me. I've done the TrailTop System project just because I thought there had to be an easier and quicker way to achieve professional-quality results when building a trailer or trailer topper at home. To prove that idea was fulfilled and the design was good, I had to make the molds for the parts, make some parts, and do some proof-of-concept builds. So during the course of this thread I built the teardrop trailer topper and then the hard cover for same trailer, and then I decided to do a proof-of-concept for the tilt-up canvas, which I've just finished. I did the tilt-up canvas mostly because I thought learning to sew would be an interesting challenge but of course also to prove that the TrailTop parts could be used for something like that. As far as I'm concerned the teardrop and the tilt-up have proven the concept and the design and met all of my design and functional requirements, so I'm done.

I never build anything explicitly to sell, and only twice have I designed and built something with the idea of having it become a commercial product (succeeded both times). I did not build the TrailTop system with either in mind, but if it becomes a commercial product that is ok with me, and if someone wants to buy my proof-of-concept builds I'd entertain an offer. But really once I'm satisfied the a project like the TrailTop system has met my design goals and functional requirements, I'm done.

At the moment, the components of the teardrop are stored in my basement, and probably the tilt-up will join them shortly.

BTW if I decide to build the clamshell roof-top tent, the way I've designed things, the tilt-up can be removed from the trailer and assembled onto the clamshell bottom half with only one small addition to the canvas components, and then it could be put back on the trailer and used as a tilt-up again. Most of my designs are modular and configurable like that.

Jeff