I am having a hard time trying to get the self tapping screws I bought to drive into the square steel tube of my frame. I thought they would work as they seemed to work for a friend of mine but I can not get them to "drill" into the steel to get the threads to catch.

I've been trying to predrill the holes but even getting a bit into the steel seems to be difficult. I'm even using a carbide bit and cutting fluid and it still takes forever.

I'm going to use them to screw the floor to the frame.

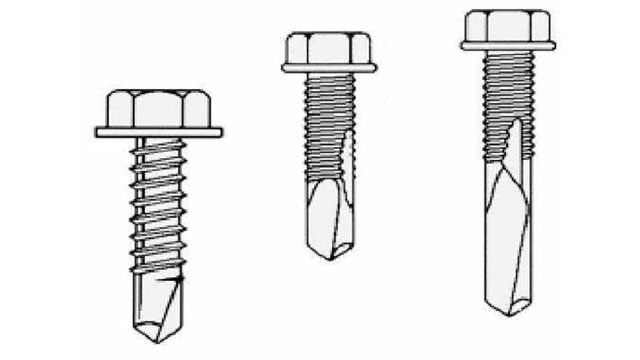

Here are the screws I'm trying to use.

Any suggestions on what I might be doing wrong?

Self Tapping Screws

14 posts

• Page 1 of 1

Self Tapping Screws

Let the fun begin!

KennyB

My Build Journal: http://www.tnttt.com/viewtopic.php?f=50&t=64385&start=15&hilit=sort+of

KennyB

My Build Journal: http://www.tnttt.com/viewtopic.php?f=50&t=64385&start=15&hilit=sort+of

-

RunnerDuck - Teardrop Master

- Posts: 167

- Joined: Sat Aug 22, 2015 4:26 am

- Location: Coupeville, Whidbey Island, Washington

Re: Self Tapping Screws

From the picture it looks like the wings below the thread will create a hole larger than the thread. I would try another type without wings.

- scooter bob

- Teardrop Advisor

- Posts: 52

- Joined: Fri Jan 30, 2015 4:19 pm