cuting 5x5 sheet of plywood effecivly

23 posts

• Page 2 of 2 • 1, 2

Re: cuting 5x5 sheet of plywood effecivly

Wood fence attached to a masonite bottom with glue & brads. Clamp it down & cut to the line. Protects the plywood, nice cut & easy-fast setup.

Build log: viewtopic.php?f=50&t=60248

The time you spend planning is more important than the time you spend building.........

The time you spend planning is more important than the time you spend building.........

-

noseoil - 1000 Club

- Posts: 1822

- Images: 670

- Joined: Sun Apr 27, 2014 8:46 am

- Location: Raton, New Mexico, living the good life!

Re: cuting 5x5 sheet of plywood effecivly

I am using 5x5 plywood on my camper build too. For the most part, we used a table saw to cut the sheets, but it took three people to control the cut on the little contractors saw.

Once the guy with the table saw left, I started using a straight edge (a cutoff from a 5x5 panel with a factory edge), and my circular saw. I know that my blade is 5" from the edge of the saw, so I would mark the line I wanted to cut, then mark a parallel line 5" away. Clamp down the straightedge down along the second line and make the cut, running the edge of the circular saw against the straightedge.

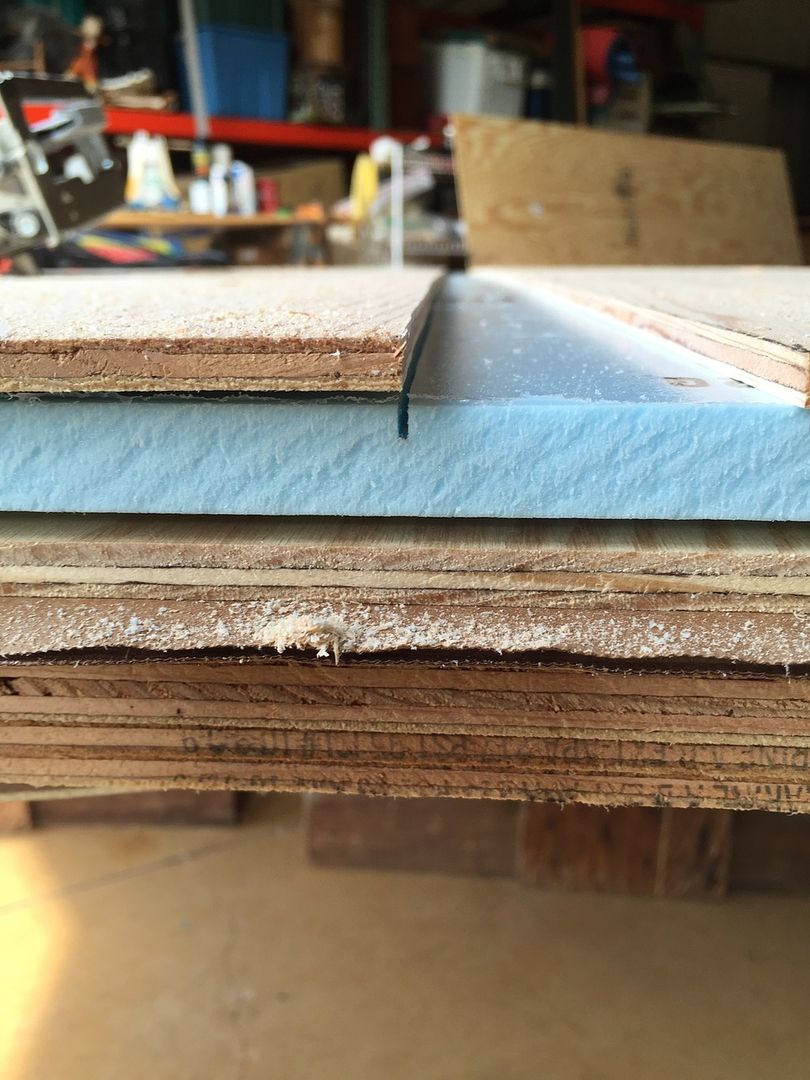

The same principal applies to routing the rabbets on my roof panels, seen here.

Note: i only used the chair to mark the lines! Never cut or route from a sitting position where the blade may pass over your body!

Good Luck! Work Safe!

Once the guy with the table saw left, I started using a straight edge (a cutoff from a 5x5 panel with a factory edge), and my circular saw. I know that my blade is 5" from the edge of the saw, so I would mark the line I wanted to cut, then mark a parallel line 5" away. Clamp down the straightedge down along the second line and make the cut, running the edge of the circular saw against the straightedge.

The same principal applies to routing the rabbets on my roof panels, seen here.

Note: i only used the chair to mark the lines! Never cut or route from a sitting position where the blade may pass over your body!

Good Luck! Work Safe!

- ThinkLibertarian

- Teardrop Builder

- Posts: 37

- Joined: Sat Feb 20, 2016 5:18 am

. In addition, the cut is not square to the surface of the plywood. What I eventually ended up doing was making the initial cut with the track saw, then going back with a router and trim bit to trim it to exact length and square the cut.

. In addition, the cut is not square to the surface of the plywood. What I eventually ended up doing was making the initial cut with the track saw, then going back with a router and trim bit to trim it to exact length and square the cut.