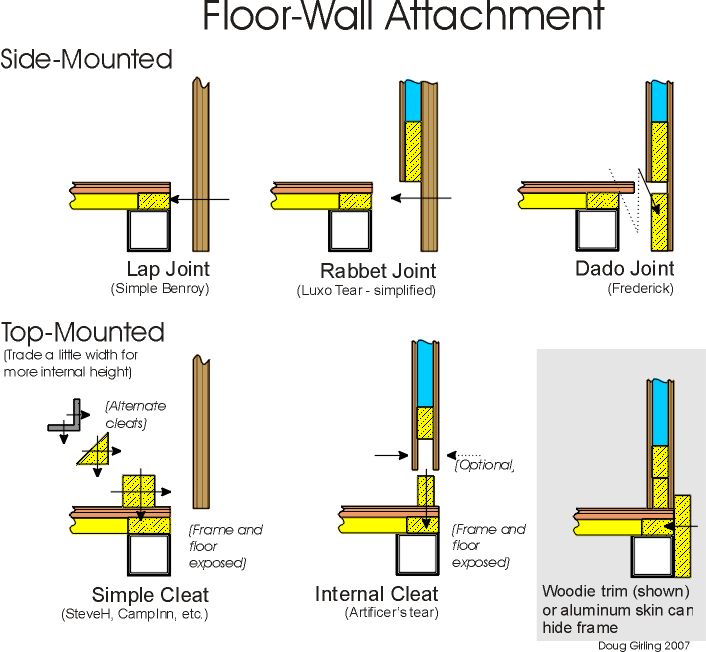

Here is DougGirling's sidewall to floor connections.

Sidewall, roof spar, hatch seal and door seal illustrations.

6 posts

• Page 1 of 1

Sidewall, roof spar, hatch seal and door seal illustrations.

I really like the illustrations that DougGirling put together for sidewall to floor connections. Does anyone have similar drawings for roof spar connections, hatch seals or door seals. Please add any drawings that you might have come up with that deal will different ways of handling these. It would be great to have a bunch of different ideas all on one thread.

Here is DougGirling's sidewall to floor connections.

Here is DougGirling's sidewall to floor connections.

-

danlott - Donating Member

- Posts: 874

- Images: 264

- Joined: Fri Mar 06, 2009 2:18 pm

- Location: Winnemucca, Nevada