Hi Stacie,

I thought I'd mention a few things/links for info purposes.

Applying plywood to the frame as a floor method is a very

simple and direct method. But I'm an advocate for insulation

as it helps with condensation, sound deadening and keeping warm/cool.

I happened to recall these insulated 'honeycomb' SIP-like panels:

http://singcore.com/http://www.superhoneycomb.com/http://www.youtube.com/watch?v=oGokTnuD ... ure=relmfuThey are located in Washington State. The panels can be

skinned in various skins - aluminum. plywood, FRP...etc.

Pricing would need to be investigated.

I wonder if the inventor was inspired by hollow core door

construction or fusuma construction when he came up with

them ? They would save alot of work and build time.

Here are a couple links for a guy using it for restoration and

modification of a 1956 Airfloat House Trailer and his daughter

using them to build a somewhat 'larger'Tiny House on a trailer

frame:

http://www.everyonecandance.com/Airfloat_Process.htmlhttp://mytinyabode.blogspot.com/ Also, since your build is small and you want quality materials I'd

forget luan and use Baltic/Finnish/Russian birch plywood instead.

It has high ply count per thickness and no voids and it's edges can be

a decorative element. And is available from 1/16th of an inch to a bit

over one inch in thickness. And natural finished birch plywood is really

beautiful. Grain pattern can vary alot though, but it is generally not

overpowering but very pleasant. Think shibui here. It was the main

traditional interior surface on most US TTs and house trailers until the

late 1960s - early 1970s:

http://www.digplanet.com/wiki/BirchAlso Google, and Google Image, birch plywood and birch plywood

furniture for examples and info and possible sources. Locally, cabinet

shops and specialty lumber yards should have that and also 4x8 sheets of

American made birch plywood. Avoid Chinese made and bigboxstore plywood.

Here's one brand that's formaldehyde-free:

http://columbiaforestproducts.com/PureBondhttp://columbiaforestproducts.com/Produ ... oodPlywoodAs you mentioned galvanizing, it is an additional cost I'm sure, but my having

dealt with quite a few rusty trailer frames/chassis in my time, I'd be in favor

of it if I could afford it. Derusting and repriming and repainting a rusted

frame underneath a trailer is more of a punishment than a project ! And

I'm not a fan of powdercoating either. From what I understand that is not

cheap either, and you can't have anything on the frame that'd be melted/

affected by the oven/heat they use to melt the powder into a finish. It is

also affected by the quality of the job/applkication when done. I have some

decorative steel yard fencing that is powder-coated and it is all sloughing off

and the steel is rusting. Instead, check out rust converting and rust encapsulating

primers and paints. They seem a better approach if one is not doing galvanized.

Just Google "rust convertion primer/paint" and "rust encapsulating primer/paint"

and there is a lot of info/brands.

The European Caravan/RV manufacturers are way ahead on building light and

coming up with new build methods. Here is an interesting approach from the

UK's Elddis brand I came across recently. They hardly use any fasteners in their

construction but have gone to all adhesive joining/bonding everything together.

Like what is used/done now in Formula 1 race cars, yachts and airplanes. Their body

panels are basically like what linixmanxxx's been doing, joined by the new all-

adhesive bonding of all the panels/components together with the new high-tech

adhesives. If you click on "Request a 2013 Brochure" in the bottom right, then in "Brochure

Downloads" click on the "2013 Tourer Brochure" and look at the 2nd and last pages that

talk about the "SoLiD" method. Also note the minimal galvanized steel chassis/frame.

http://www.elddis.co.uk/ Since you want to keep a rear door/hatch just have a look at these:

http://crickettrailer.com/index.htmlIt's not very pretty, but I love the functional approach they've taken.

Also, I came across this recently too: The "Cross-Over Trailer" concept by Ross

Design, the in-house design function of the Vohringer Group, a German caravan

[wohnwagen] interior component supplier/manufacturer. It's intended to meld the

tow vehicle's air movement into the trailer's for an aero benefit. It is also light

weight and narrow and has a large rear opening:

http://www.voehringer-gmbh.net/rossdesi ... ossdesign/http://www.v-group.com/uploads/pdfs/CRo ... %20eng.pdfI don't know how wedded you are to the radiused ends of the older style TDs and

canned ham TTTs [I suspect you really like the "cute" factor in those rounded end

designs] but I thought this was an interesting modern flat panel design with some

'aero-ness' thrown in.

I've just remembered a way you could keep the rounded ends and still have a rear

hatch as well as some covered rear space. This is based on a camper trailer I saw

a LONG time ago when I was a kid and went with my Dad looking for/at TTTs/campers.

One that we looked at had the canned ham profile's rounded ends - which were almost semicircular

actually. It was sort of what we on the forum would call a "slouchy" TD. The body was about

6ft wide and about 10ft long and 5ft tall. The rear semicircular end was hinged at the

roof where the radius ended and the roof plane became flat. The whole end cap lifted

up and it became a mini-barrell-vaulted roof supported by two poles at the rear corners. This

provided a roof over the galley's work area. There were also canvas sidewalls available to enclose

that area under the roof if wanted. The rear galley area is built in at the back

like a TD's, except that the galley and bulkhead wall ended @ 20in from the passenger

side wall so that there was a doorway/opening into the sleeping compartment which

had double bed sized bunks located longitudinally front-to-back and a front closet at

the end of the "hallway" on/in the front curved section, which was also thusly positioned

ahead of the passenger side sleeping compartment side door. I believe there was

a small interior door closing off the rear entrance to the sleeping compartment too.

There was a single pane longer horizontal shaped window for each bunk level on the

trailer body's driver's side and an entry door and then a square two pane awning window

on the trailer body passenger side, between the entry door and the rear of the trailer.

-Anyway- maybe you could utilize the rear liftup mini-barrel-vault roof aspect of it if

you are going to keep rounded ends on the profile.

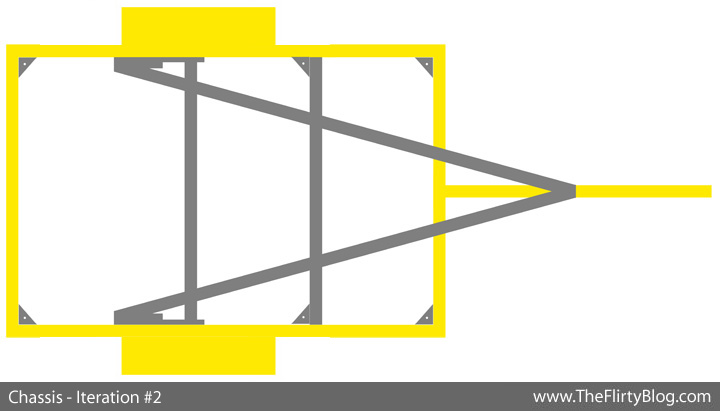

Click on Pic to see larger view:

Maybe a variation on that could meet your needs. You could even have the rear galley be a

movable unit, that'd swing out 90 degrees from the travel position like a lot of the Australian

off-road campers kitchens do.

Wow, time to close this up ! Sorry for being so lengthy, I must have gotten on a roll here

somewhere along the way !

Cheers,

Norm/mezmo

If you have a house - you have a hobby.

Fred

Fred