Show me your hatch detail please

38 posts

• Page 3 of 3 • 1, 2, 3

I agree with Miriam. We need to put together an album of closeups on galley hatches and hinges and such. I'm still trying to figure out which way to do mine as well.

-

thobbs - Teardrop Master

- Posts: 103

- Images: 21

- Joined: Thu Oct 13, 2005 12:23 pm

- Location: Utah

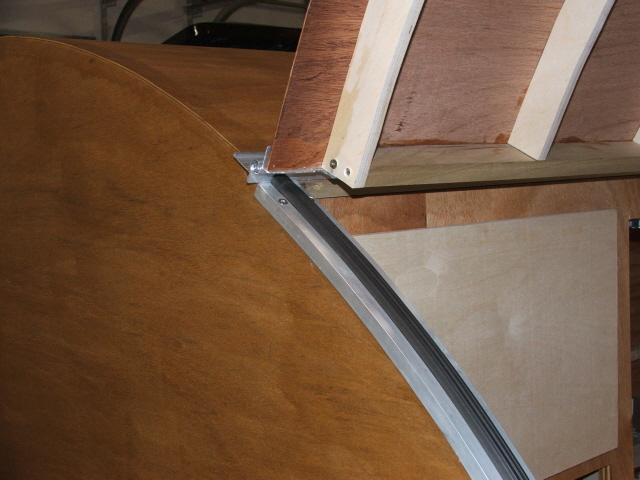

Here's what I got.

You brought this topic up, so I went out and did it. 1/2" angle inside and out (annealed and bent to the radius). Aluminium valley flashing cut to fit in between and Grants hatch seal. The side walls are notched 3/8" per the generic benroy plans. Notice Grants hinge sits above the angle.

You brought this topic up, so I went out and did it. 1/2" angle inside and out (annealed and bent to the radius). Aluminium valley flashing cut to fit in between and Grants hatch seal. The side walls are notched 3/8" per the generic benroy plans. Notice Grants hinge sits above the angle.

If you do what you've always done, you'll get what you've always got.

-

bledsoe3 - 3000 Club

- Posts: 3694

- Images: 112

- Joined: Tue Jun 07, 2005 5:55 am

- Location: Oregon, Portland

Bledso,

Bledso,

What a great picture!!!! I hadn't realized there were 3 different pieces of metal on the door either.

What a great picture!!!! I hadn't realized there were 3 different pieces of metal on the door either.  Seems you have solved 2 major mysteries for me with one very fine close up.

Seems you have solved 2 major mysteries for me with one very fine close up.