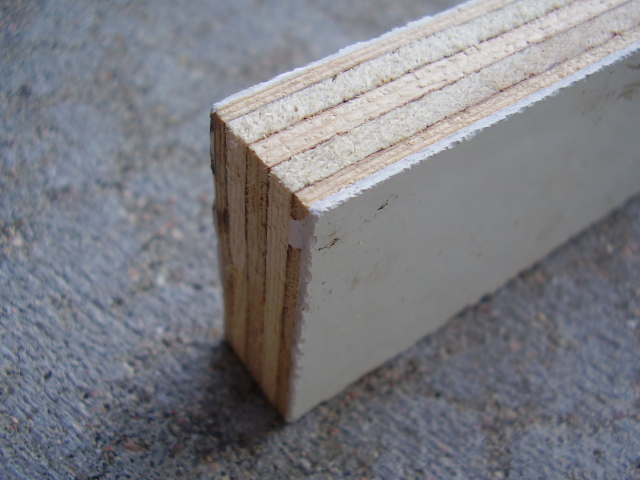

I built my: sandwich floor, storage floor, shelves/cabinets, side walls, bulkheads out of FRP (Fiberglass Reinforced Plywood) It is the stuff thay make truck bodies out of (like Ryder trucks). The final product is great. Already finished inside and out. It also opened up the size constraints of normal plywood. I bought 3 sheets, 8'x8' and one sheet, 8'x25'. It is HORRABLE to work with. It cuts, routes and sands just like plywood (dulls blades quick) BUT the fiberglass gets everywhere. I worked with a resperatior and face shield. It was in the 90s when I was working with it and I itched for weeks. I would rather roll around in my attic insulation in the summer. I like the finished project. Would I use it again? I don't know. I had to run all wiring in the ceiling, not a problem, untill I wanted porch lights on the side walls and reading lights on the galley bulkhead. I had to carefully drill down into the endply it my light placement, scarry. Also any fasteners going thru the side walls had to be of finished quality and evenly spaced. Everything worked out. I'm not sorry that I used it. It is now pretty much indistructable, maybe even bear-proof. (Did I say that out loud?)