Aluminum Molding

Hi All,

This weekend I installed the aluminum molding around my door frames and the galley wall tops.

I've never worked with aluminum before and it took me a bit to figure out a good method to cut, trim, and install the molding.

I thought I'd share what worked for me...

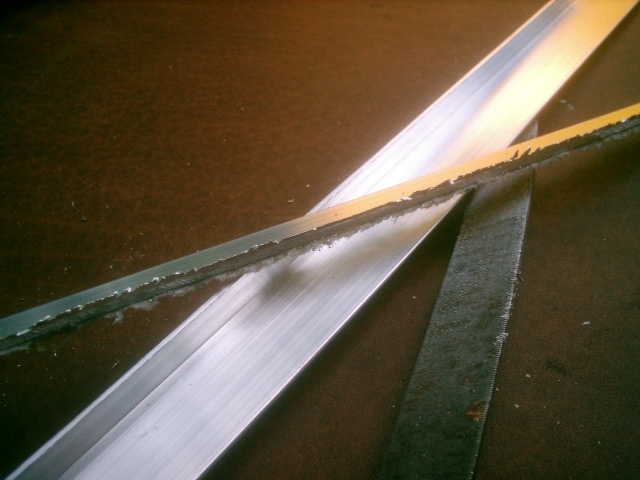

The walls on my trailer are 1.5" thick so I used 3/4" angle, but I had to trim one side down to 3/8" to bend.

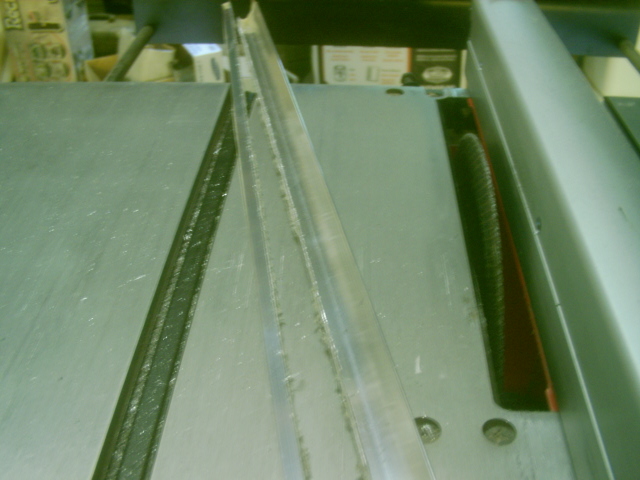

I used a metal cutoff blade on my table saw for the cut and trim of the molding. Home Depot sells them for about $5.00. You'll need eye protection, gloves, and long sleeve shirt.

I also masked the piece I was cutting, I found that it helps reduce the amount of flying particles.

I trimmed the angle molding to 3/8" on one side...

Shown are the rough pieces of molding after cutting...

Then I filed the molding, which was easy, just time consuming...

Here is the clean molding and the rough piece of scrap...

Next I marked the spacing for the screw holes and used a drill bit as a quick center guide...

Here I temporarily install the molding, notice the clamps to hold it in place...

Next I countersunk the holes for the screw heads to sit flush...

Here is the Galley Wall top with one piece of molding...

I was able to bend the molding on the wall without having to heat the molding. I used clamps and to keep the molding close to the wall and went slow and gentle...

Ta Daaa...

Hope this helps...

-phil

This weekend I installed the aluminum molding around my door frames and the galley wall tops.

I've never worked with aluminum before and it took me a bit to figure out a good method to cut, trim, and install the molding.

I thought I'd share what worked for me...

The walls on my trailer are 1.5" thick so I used 3/4" angle, but I had to trim one side down to 3/8" to bend.

I used a metal cutoff blade on my table saw for the cut and trim of the molding. Home Depot sells them for about $5.00. You'll need eye protection, gloves, and long sleeve shirt.

I also masked the piece I was cutting, I found that it helps reduce the amount of flying particles.

I trimmed the angle molding to 3/8" on one side...

Shown are the rough pieces of molding after cutting...

Then I filed the molding, which was easy, just time consuming...

Here is the clean molding and the rough piece of scrap...

Next I marked the spacing for the screw holes and used a drill bit as a quick center guide...

Here I temporarily install the molding, notice the clamps to hold it in place...

Next I countersunk the holes for the screw heads to sit flush...

Here is the Galley Wall top with one piece of molding...

I was able to bend the molding on the wall without having to heat the molding. I used clamps and to keep the molding close to the wall and went slow and gentle...

Ta Daaa...

Hope this helps...

-phil