Untralight foam topper idea.

Ok, being an ultra noob, I've got an idea.

I'm trying to build a pop-up TD with an ultra light top. The base of the camper will be a rectangular box and the upper walls and top will pop-up 3ft.

The problem is to make it super light so I can tow it behing a small car.

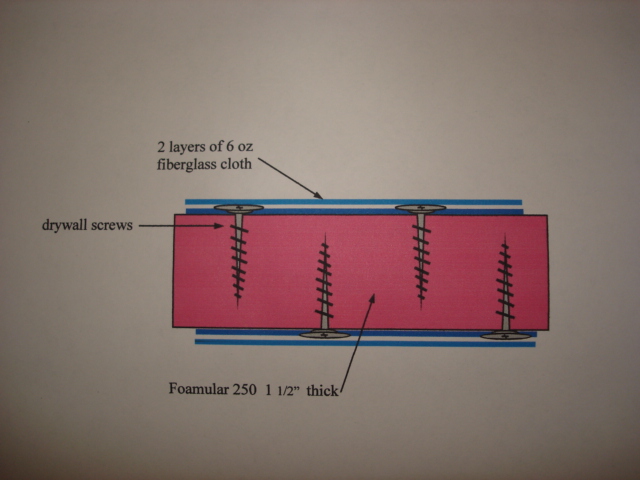

The proposed solution for the top is to make it entirely out of 1.5" thick Foamular 250 (pink styrofoam insulation) covered with 2 thin layers of 6-8oz fiberglass. This will be a fairly large top (about 500sq ft of total surface area inside and out) To prevent the fiberglass/epoxy from delaminating from the eps, I propose to use drywall screws spaced about every foot between the layers of cloth.

I calculate that the weight of this 15'x5'3"x3' monstrosity will only come to about 160lbs with foam, glass and screws. Of course the fiberglass shell will only be .026" thick.

The question is, will it work without cracking or delaminating?

Here's an illustration of my proposed topper cross-section.

I'd love for you guys to tell me why it won't work. Any ideas to make it work?

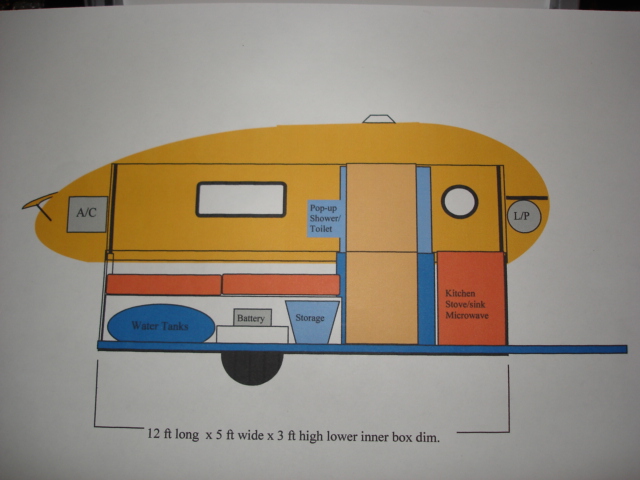

Here is a drawing of the proposed pop-up in the up position (repost.)

I've decided to do away with the side door to improve it's structural integrity. Instead I will use a rear entry (no porn jokes please), with a 26" wide hatch: the bottom of the rear apex droping down, forming steps, and the top hinging upwards on struts in classic TD fashion. Sort of like entering a flying saucer. The a/c will also be relocated to the bow of this land yaght, attached to the 5'x12' inner bottom and above a tongue mounted, horizontal l/p tank. The bottom will be a more conventional, foamular-core, wood-framed build. The only twist will be that it'll be mounted on an aluminum trailer with the 3' high sides framed in aluminum angle and strapping for rigidity.

Has anyone tried anything like this before?

I'm trying to build a pop-up TD with an ultra light top. The base of the camper will be a rectangular box and the upper walls and top will pop-up 3ft.

The problem is to make it super light so I can tow it behing a small car.

The proposed solution for the top is to make it entirely out of 1.5" thick Foamular 250 (pink styrofoam insulation) covered with 2 thin layers of 6-8oz fiberglass. This will be a fairly large top (about 500sq ft of total surface area inside and out) To prevent the fiberglass/epoxy from delaminating from the eps, I propose to use drywall screws spaced about every foot between the layers of cloth.

I calculate that the weight of this 15'x5'3"x3' monstrosity will only come to about 160lbs with foam, glass and screws. Of course the fiberglass shell will only be .026" thick.

The question is, will it work without cracking or delaminating?

Here's an illustration of my proposed topper cross-section.

I'd love for you guys to tell me why it won't work. Any ideas to make it work?

Here is a drawing of the proposed pop-up in the up position (repost.)

I've decided to do away with the side door to improve it's structural integrity. Instead I will use a rear entry (no porn jokes please), with a 26" wide hatch: the bottom of the rear apex droping down, forming steps, and the top hinging upwards on struts in classic TD fashion. Sort of like entering a flying saucer. The a/c will also be relocated to the bow of this land yaght, attached to the 5'x12' inner bottom and above a tongue mounted, horizontal l/p tank. The bottom will be a more conventional, foamular-core, wood-framed build. The only twist will be that it'll be mounted on an aluminum trailer with the 3' high sides framed in aluminum angle and strapping for rigidity.

Has anyone tried anything like this before?