Page 1 of 1

Whoops! Building CABINETS, not closets--facing frame size??

Posted:

Tue Jun 19, 2007 7:36 pmby kayakrguy

I goofed on earlier posting....typed closet when it should have been cabinets!!! mea culpa!

Hi folks,

Finally, I am getting to the cabinets. I plan on sliding doors for convenience and space reasons. I plan to mount them in the facing frames of the cabinets.

I need advice on the size of the lumber required to accept deep enough grroves to hold the doors without them jumping out etc. I plan on using 1/8" luan for the doors so my tracks need to be about 1/4 inch wide, which suggests 3/4 inch thickness at the least--is that too skimpy??

Those of you who built sliders--what sizr limber did you use for the frame?

Hope all is well with everyone!

Thanks,

Posted:

Tue Jun 19, 2007 8:01 pmby mikeschn

You can hit the edit button and edit any of your previous messages...

Mike...

Posted:

Tue Jun 19, 2007 8:15 pmby Miriam C.

Some suggested reading.

Steve Fredericks current build

Tom Swensons build

http://www.tomswenson.com/teardrop/

Posted:

Wed Jun 20, 2007 10:04 amby Keith B

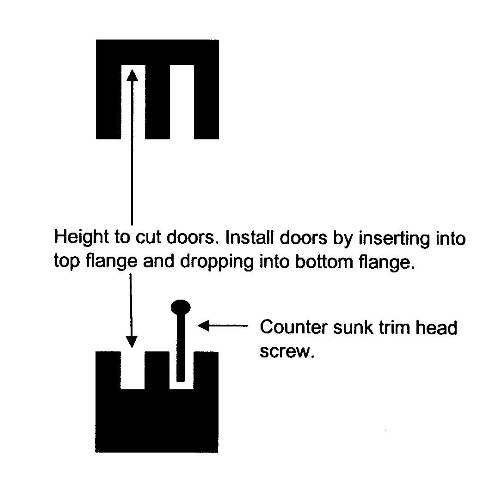

See my album... I built some sliding bypass doors up front. The material is 1" wide and 3/4 thick. I cut the grove w/ a dado blade. The 1" was only so I could put the screws on the inside and you wouldn't see them, however, you can get whats called a trim head screw and they will fit down inside the dado grove itself. I used 1/8 hardboard (peg board) for doors...gives ventilation for the converter, etc. that's behind the doors. The top board should have a deeper grove than the bottom by about 1/4"; then you cut your doors the distance from the inside of the top grove to the top of the board on the bottom...they will not jump out...well, mine didn't anyway.

I'll try to draw a layout and post it for you.

Posted:

Wed Jun 20, 2007 10:20 amby Keith B

Here ya go:

Trim Head Screw:

Posted:

Wed Jun 20, 2007 10:59 amby sid

Good explanation and nice job on the doors. I like it........

Posted:

Wed Jun 20, 2007 10:35 pmby bdosborn

Hey Keith,

Thats a great idea to use pegboard for cabinet doors and I just realized I never looked inside your trailer when we were in Minden.

Bruce

Posted:

Thu Jun 21, 2007 3:11 amby Classic Finn

Keith I really like what youve done with them cabinets...

Great looking tear..

One thing I noticed was the ceiling ply.. What is that? Is it Birch? Or is it somthing else?

MidSummer Greetings from Scandinavia.

Classic Finn

Posted:

Thu Jun 21, 2007 10:33 amby Keith B

Hey thanks yall...yeah, the pegboard was laying around, but even so, it's only about $8 a sheet and I needed ventilation for the converter. I also used 1/4" hardboard (without the holes) for the galley cabients... Eventually I will finish the galley out with raised panel doors but this was what I had laying round and figured if anything did leak or I didn't like the layout I would be out VERY minimal $..... they actually work quite well and the stuff lays FLAT and you can still put a nice bevel on it with a router... it was ugly, but more importantly, it was functional and that's all I needed for the first outing. The ceiling is 36x72 door skins ($6)...cheap and easy, with 2 coats of Watco Danish Oil.. no poly.. I tend to go for the VERY natual look in wood - I use lots of oil.. danish, tongue, etc. For "water-proofing" outside furniture I use regular 'ole vegetable oil, repels water like a dream...when it dries out, gets a scratch, whatever, just wipe another coat on and you'll never notice it; that's also what I use for finishing out cutting boards - TiteBond II and vegetable oil are both FDA approved for cutting boards.

Great looking tear..

Great looking tear..