Plastic Hinge install questions - Pictures and Q's added

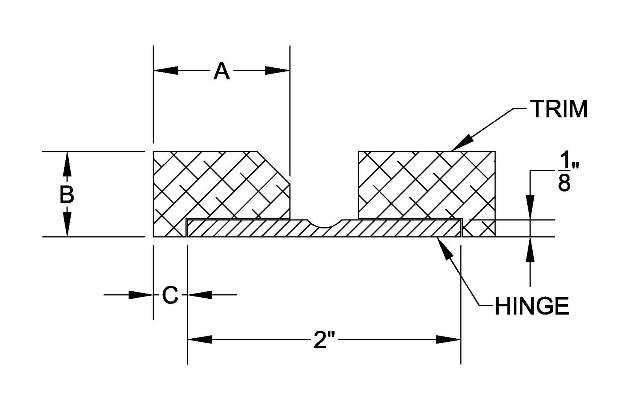

I have purchased the Plastic Hinge from McMaster-Carr for the hatch and I need some help on the trim covering it.

I have a drawing to help.... Remember I am using WOOD trim, not alum and I would like to countersink the screws and use plugs.

Do I have the right idea on how to do this?? If so, what would you make dimensions A, B & C?

Thanks for your help.

Mk

I have a drawing to help.... Remember I am using WOOD trim, not alum and I would like to countersink the screws and use plugs.

Do I have the right idea on how to do this?? If so, what would you make dimensions A, B & C?

Thanks for your help.

Mk

Jim

Jim You okay Geron?

You okay Geron?

However, that is currently being debated by my wife and boys.

However, that is currently being debated by my wife and boys.