DIY paint removal tool and my paint stripping experieces.

As some of you are aware, I am in the process of stripping the paint from my TTT so that I can seal the plywood properly with epoxy as I should have done to start with, but, alas, didn’t.

Removing paint is a very slow and trying process. You can sand it off, use a chemical stripper, or a heat and peel process. These are my experiences with all three methods and my own solution to a pretty good heat and strip tool that I “made”.

The Chemical stripper works pretty well, and is probably requires the least manual labor. However, it is the most time consuming as it takes either two applications to strip off most of the paint, and then still requires some use of a scrapper and heat gun or sander to get all of the patches of paint off. I also tried one application of stripper, which left a lot of paint still on, and extensive use of the scraper and heat gun to remove the rest. And on the downside, the stripper has strong fumes requiring wearing a respirator mask that is hot and confining. Gloves should be worn as it’s caustic, but I skip those. I do get bits on my skin that I have to wash off quickly as it does burn the skin.

Sanding alone (80 grit was the coarsest I could find for my orbital sander) takes a lot of time and work, especially on the top were I had 3-4 coats of paint to remove, but eventually gets it off. Again, this requires wearing a dust mask that isn’t as bad as the respirator, but still, an annoyance..

Then, I tried using just the heat gun and scraper. Actually, my scraper is a 2” putty knife with the corners of the blade rounded so I don’t dig into the plywood. This works, but is very slow, but faster than using the chemical stripper and waiting 15-20 minutes between coating and scraping. But, rather than taking 15-20 minute breaks, I am constantly working with the heat. And, it takes coordination between aiming the gun with one hand and pushing the putty knife with the other.

What’s the answer? I decided heat was the best way, but there had to be a better method. I went to Home Depot to look for ideas. I couldn’t find an electric tool to remove paint with heat, but did spot a package of Milwaukee heat gun accessories. In it was a flat blade “glass protector nozzle”. That got me to thinking. I bought it and went home.

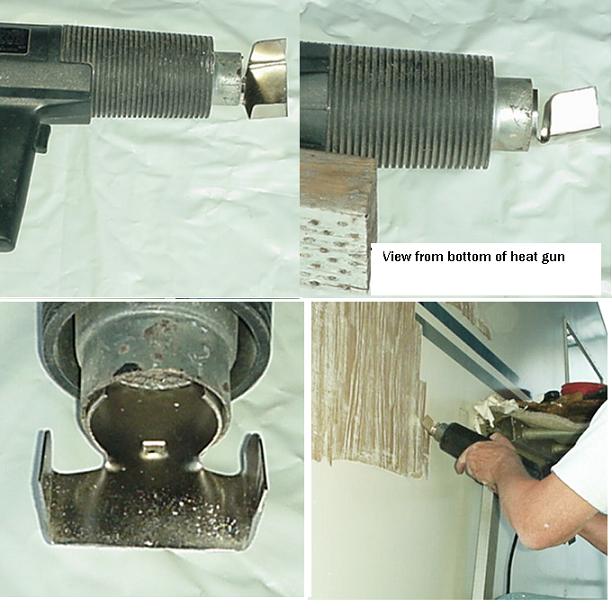

The nozzle fits a Milwaukee gun, and mine is a B&D. It woudn’t fit around my heat gun nozzle, but it did fit inside it. I decided to make a heated scraper. I needed about a 2” width. I could have cut off the ends of the blade, but instead, I bent them up to keep the heat from spreading out. I used a grinder to cut away some of the bent up ends to keep them off the wood and ground a beveled edge across the front of the scraper part. I slipped it into the gun and bent it up slightly. It’s positioned so that I hold the heat gun with the handle out to my right.

I turn on the heat gun, lock it in the on position, give it about 15 seconds to heat the scraper blade. Holding the handle out to the side in my right hand and the top of the barrel in my left, I direct the heat onto the paint until it starts to bubble. Then, I press the scraper down onto the paint and push forward (or up if on a wall). The heat flows onto the paint, but also heats the blade and I think that the heated blade does as much as the heat flow to soften the paint. I peel off a strip from 1” to 1 ½” wide and it takes off about an inch of length of paint per second. That’s slow, but steady and using both hands to control the scraper pressure works better than one. I think this is the way I’ll take off most of the remainder of the paint.

Bottom line:

Chemical stripper: Pros-less manual labor, takes off most of the paint with two applications. Cons-Cost, waiting for stripper to soften paint, caustic and strong fumes require protective gear, requires removing residue with paint thinner.

Power Sanding: Pros-Gets the paint off cleanly (but dusty). Cons-cost of sand paper, dust requires wearing a mask, slow process.

Heat Gun and scraper: Pros-gets most paint off with one pass, clean, no residue to wash off. Cons-slow process, cost of electricity (minimal).

All three processes still require final power sanding to clean wood for repainting.

Removing paint is a very slow and trying process. You can sand it off, use a chemical stripper, or a heat and peel process. These are my experiences with all three methods and my own solution to a pretty good heat and strip tool that I “made”.

The Chemical stripper works pretty well, and is probably requires the least manual labor. However, it is the most time consuming as it takes either two applications to strip off most of the paint, and then still requires some use of a scrapper and heat gun or sander to get all of the patches of paint off. I also tried one application of stripper, which left a lot of paint still on, and extensive use of the scraper and heat gun to remove the rest. And on the downside, the stripper has strong fumes requiring wearing a respirator mask that is hot and confining. Gloves should be worn as it’s caustic, but I skip those. I do get bits on my skin that I have to wash off quickly as it does burn the skin.

Sanding alone (80 grit was the coarsest I could find for my orbital sander) takes a lot of time and work, especially on the top were I had 3-4 coats of paint to remove, but eventually gets it off. Again, this requires wearing a dust mask that isn’t as bad as the respirator, but still, an annoyance..

Then, I tried using just the heat gun and scraper. Actually, my scraper is a 2” putty knife with the corners of the blade rounded so I don’t dig into the plywood. This works, but is very slow, but faster than using the chemical stripper and waiting 15-20 minutes between coating and scraping. But, rather than taking 15-20 minute breaks, I am constantly working with the heat. And, it takes coordination between aiming the gun with one hand and pushing the putty knife with the other.

What’s the answer? I decided heat was the best way, but there had to be a better method. I went to Home Depot to look for ideas. I couldn’t find an electric tool to remove paint with heat, but did spot a package of Milwaukee heat gun accessories. In it was a flat blade “glass protector nozzle”. That got me to thinking. I bought it and went home.

The nozzle fits a Milwaukee gun, and mine is a B&D. It woudn’t fit around my heat gun nozzle, but it did fit inside it. I decided to make a heated scraper. I needed about a 2” width. I could have cut off the ends of the blade, but instead, I bent them up to keep the heat from spreading out. I used a grinder to cut away some of the bent up ends to keep them off the wood and ground a beveled edge across the front of the scraper part. I slipped it into the gun and bent it up slightly. It’s positioned so that I hold the heat gun with the handle out to my right.

I turn on the heat gun, lock it in the on position, give it about 15 seconds to heat the scraper blade. Holding the handle out to the side in my right hand and the top of the barrel in my left, I direct the heat onto the paint until it starts to bubble. Then, I press the scraper down onto the paint and push forward (or up if on a wall). The heat flows onto the paint, but also heats the blade and I think that the heated blade does as much as the heat flow to soften the paint. I peel off a strip from 1” to 1 ½” wide and it takes off about an inch of length of paint per second. That’s slow, but steady and using both hands to control the scraper pressure works better than one. I think this is the way I’ll take off most of the remainder of the paint.

Bottom line:

Chemical stripper: Pros-less manual labor, takes off most of the paint with two applications. Cons-Cost, waiting for stripper to soften paint, caustic and strong fumes require protective gear, requires removing residue with paint thinner.

Power Sanding: Pros-Gets the paint off cleanly (but dusty). Cons-cost of sand paper, dust requires wearing a mask, slow process.

Heat Gun and scraper: Pros-gets most paint off with one pass, clean, no residue to wash off. Cons-slow process, cost of electricity (minimal).

All three processes still require final power sanding to clean wood for repainting.

Danny

Danny