Ideas to hide fasteners on a wood roof

I am mulling over options for attaching a the outside layer of the roof.

To preface, I have Grants profile, the Generic Benroy plans for construction and what all the excellent build photos can show me, so that gives me just about everything, not to mention a healthy dose of my own ideas, but sometimes I run into little snags. That's half the fun! There are always a variety of ways that people have invented on how to do things, and to me that is one of the most exciting parts of this, is that there is so much freedom.

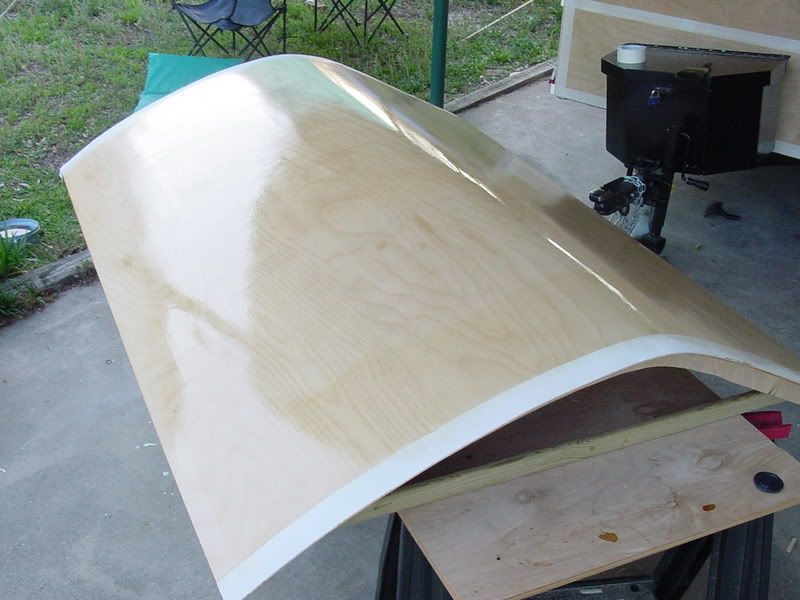

So anyway, I am going to do the 1/8 Luan roof on a woody using side trim to cover screw holes for the spars and cabinets, but I am perplexed regarding the roof. Steve Cox's is the style I am looking to do. (Nice work Steve!)

I am thinking there are two options, glue only, and let it float like with Aluminum, but wood likes to spring back alot more than aluminum! So to use a trim nail gun and filler like you would use for crown molding would be my second choice. I guess screws would be fine if it was going to be painted or covered, I just can't remember seeing how it could be done.

Also, I can handle a strip every 4ft for when a new sheet starts, it's the parts in between I am wondering about.

Any input on what you guys have done would be awesome.

To preface, I have Grants profile, the Generic Benroy plans for construction and what all the excellent build photos can show me, so that gives me just about everything, not to mention a healthy dose of my own ideas, but sometimes I run into little snags. That's half the fun! There are always a variety of ways that people have invented on how to do things, and to me that is one of the most exciting parts of this, is that there is so much freedom.

So anyway, I am going to do the 1/8 Luan roof on a woody using side trim to cover screw holes for the spars and cabinets, but I am perplexed regarding the roof. Steve Cox's is the style I am looking to do. (Nice work Steve!)

I am thinking there are two options, glue only, and let it float like with Aluminum, but wood likes to spring back alot more than aluminum! So to use a trim nail gun and filler like you would use for crown molding would be my second choice. I guess screws would be fine if it was going to be painted or covered, I just can't remember seeing how it could be done.

Also, I can handle a strip every 4ft for when a new sheet starts, it's the parts in between I am wondering about.

Any input on what you guys have done would be awesome.