I plan to dry fit my walls, mark and drill all the spar locations and the bulkhead locations this weekend. Afterwards, I’ll disassemble everything and insulate the walls and attach the interior wall skins – And—cut out the “dreaded hatch notch”. Thanks to all the great help on this forum, I think everything should go well. But, I confess I’ve never even seen a finished teardrop except the photos on this board. So I’m a little fuzzy on the best way to seal the hatch (let alone the doors which will come later). I could use some opinions:

Is it better to cut the full 3/8” notch out of the side walls (as in Generic Benroy plans) or use my router and cut a sort of rabbit on the outside edge where the hatch will meet the side walls, something like ½ inch wide x ¼ or 3/8” deep for the weather stripping? It seems like the router approach leaving a “hard lip” next to the galley would be the easiest to do and perhaps the most efficient, but, I have no experience to go by. I can do it either way, but, would like some thoughts on the best and most leak proof way to go. BTW my walls are 1/4" outer skin, 3/4" framing and 1/8" interior sandwich style construction.

Thanks,

Mike

Hatch Seal Method

8 posts

• Page 1 of 1

I know what you're asking, but it's late and I'm tired... and I don't have the Lil Diner and the Benroy sitting in the driveway to look at...

But let me dust off the old cobwebs...

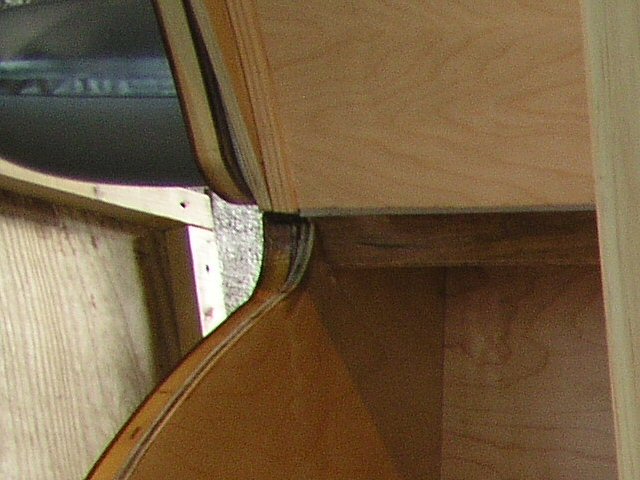

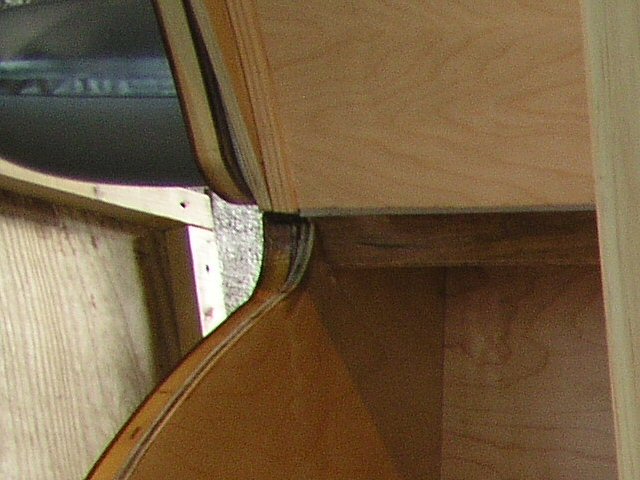

Look at this pic... the black stripe under the hatch is the weather stripping. It is 3/4" wide. And it sits on the plywood walls, which are also 3/4" wide.

If you were to route out a rabbit, let's say you made it 3/8 x 3/8. It would work, as long as you used insulation that was say, perhaps, 1/2" thick. That way you could compress it for your sealing effect.

I don't think you'll gain much unless you build a hatch, like was on the Lil Diner...

But as you can see that is quite a bit more complicated. You might want to get Steve Fredericks manual to help you with that if you decide to go that route.

Mike...

But let me dust off the old cobwebs...

Look at this pic... the black stripe under the hatch is the weather stripping. It is 3/4" wide. And it sits on the plywood walls, which are also 3/4" wide.

If you were to route out a rabbit, let's say you made it 3/8 x 3/8. It would work, as long as you used insulation that was say, perhaps, 1/2" thick. That way you could compress it for your sealing effect.

I don't think you'll gain much unless you build a hatch, like was on the Lil Diner...

But as you can see that is quite a bit more complicated. You might want to get Steve Fredericks manual to help you with that if you decide to go that route.

Mike...

The quality is remembered long after the price is forgotten, so build your teardrop with the best materials...

-

mikeschn - Site Admin

- Posts: 19202

- Images: 475

- Joined: Tue Apr 13, 2004 11:01 am

- Location: MI