Beware: Long, possibly boring, post!

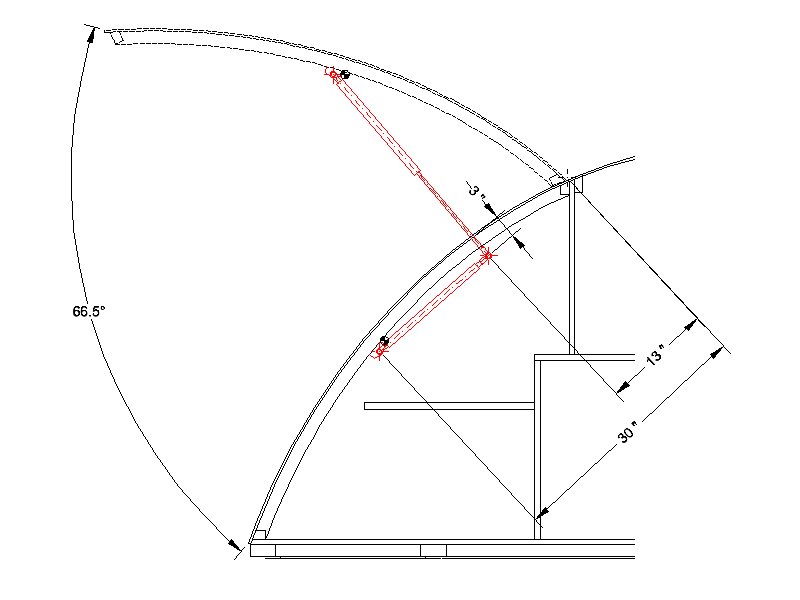

I once designed and analysed the gas springs to lift a big boat hatch and I thought I'd try repeating the same work for a teardrop hatch. Hey, it is nerdy, but when there's some real serious nerding to be done, I'm your man! Here's my layout for the 56" long hatch of the 'Trailer for Two':

A few general points on this:

- It is instinctive to put the thin rods of the gas springs to the top and the big tubes to the bottom, but this is wrong. Check your car's trunk and you'll find them the other way up. This is because the spring is damped as it reaches full extension, but only if it is in a rod down/tube up orientation.

- I put the spring's attachment to the hatch as far away from the hinge as possible, to put the springs effort as near the centre of gravity of the hatch as possible - this reduces how much of the hatch is cantilvered past the springs. This approach puts a bigger load on the sidewalls, but they're big strong things that can take it.

- The gas spring shown here is the SPD-GS-3100 from

SPD Hardware - it says it is also available from NAPA Auto Parts stores. This spring is 28" extended and 16.5" compressed, though I've only used 17" to make sure it doesn't bottom out.

And one final point:

This arrangement works for this design. The measurements and results will not apply to your design if it's different, though the principles will.

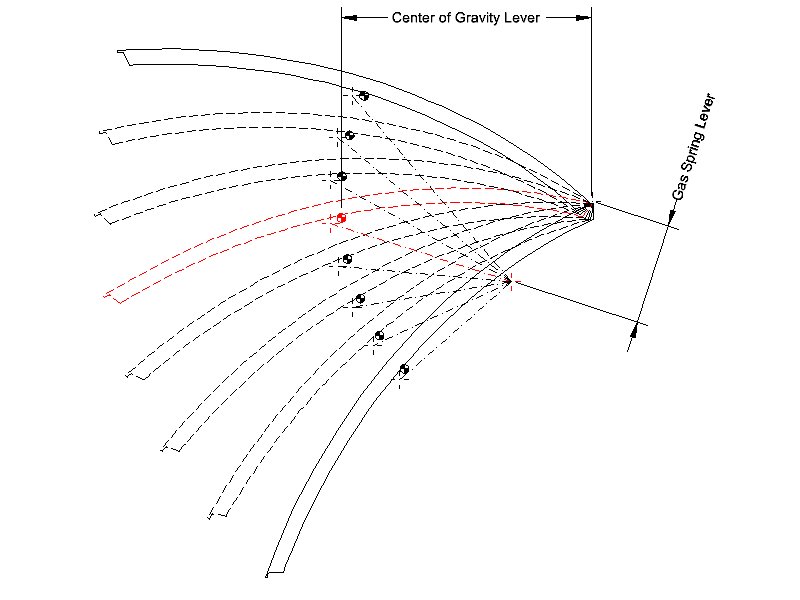

To analyse the hatch and springs, I drew the hatch opened at six intermediate positions, as well as at fully open and fully closed:

The hatch's weight exerts a moment (or torque) around the hinge so I mesured the lever of the hatch's (assumed) centre of gravity. The gas springs exert an opposite moment around the hinge, trying to lift the hatch, so I measured the lever of the gas springs.

Here is a table of the results, based on a 30lb hatch and two 100lb gas springs. That sort of hatch weight allows for two 1/8" ply skins and four internal ribs.

A little explanation:

- Columns 2 and 3 calculate how the hatch weight is 'pushing down'.

- Columns 4 and 5 calculate how the gas springs are pushing up.

- Column 6 calculates the net result - a positive number is the hatch trying to close itself and a negative number is the hatch trying to open up.

- Column 7 calculates the force you need to apply at the handle or edge of the hatch too open or close it.

What these results show is that:

- When closed, the hatch does not want to spring open on its own (which I think is a good idea) - you need to apply a 9lb pull on the handle to start the hatch opening.

- Very quickly, in less than 10 degress of opening, the gas springs take over and try to push the hatch open for you.

- When fully open, you have to apply a 32lb (downward) pull on the hatch to get it to close and you will have to keep pulling it down until it is nearly closed.

So I also tried an alternative with a 40lb hatch and two 50lb gas springs. That's about the weight of the hatch above with a .032" aluminum covering.

Not surprisingly, a heavier hatch with much lighhter gas springs shows a different result:

- It takes a 14lb lift to start the hatch opening and you have to keep on lifting past half way.

- The gas springs will support the hatch in the open position, but it only takes a 5lb pull on the hatch to start it closing and it is likely to drop all the way down.

I think this combination of hatch weight and gas springs is dangerous - it's too small a force to start it closing (a puff of wind might do it, a breeze certainly will) and it's likely to drop all the way.

So what does all this nerdiness teach us? Well, it shows me that this is a fairly difficult thing to analyse and that there no universal answers that can be used by everyone - the number of different variables that can be changed in different designs is very high. One thing is that apparently quite powerful gas springs (2 x 100lb in the first example) do not make it too hard to close the hatch so, if you are in doubt about what to do for your trailer, it would be sensible to go for higher powered gas springs - for example, even if two 150lb gas springs were used in first example, the force to start the hatch closing would still be 'only' 56lb.

I'd be happy to answer anyone's questions but it's taken about 4 hours to do this work, so I'm not volunteering to repeat it for anyone who asks!

Andrew (in training to be a Nerd-in-Chief)