Page 1 of 1

Question about 5 foot wide

Posted:

Fri Sep 05, 2008 1:11 amby afzski

Hi, I'm Alex and I have been looking at building a teardrop for a long time - and have been digesting the decision of building a 5 foot wide vs the 4 foot - and I believe the decision to go 5 foot is better - but when I look at the many designs and read the construction blogs - I cannot see how to do the outer top skin in one 5 foot width for the curve in the font and the back hatch - all the 1/4 - luan plywood I find is only 4 ft wide - how do you make up the difference?????

Do you have to splice the wood??? Build it up ???

Thanks for the help

Alex

Posted:

Fri Sep 05, 2008 1:23 amby Gage

Use 4' wide and lay it cross wise. You also don't need 1/4", use 1/8" birch ply, not luan. Laun is to brittle. Just the way I did it. It's not law.

Posted:

Fri Sep 05, 2008 3:53 amby asianflava

Gage wrote:Use 4' wide and lay it cross wise. You also don't need 1/4", use 1/8" birch ply, not luan. Laun is to brittle. Just the way I did it. It's not law.

What a coincidence, that is how I did mine too.

Posted:

Fri Sep 05, 2008 4:00 amby Gage

asianflava wrote:What a coincidence, that is how I did mine too.

Great minds think a like.

Posted:

Fri Sep 05, 2008 6:27 amby Jiminsav

thats the only way to do it.

Posted:

Fri Sep 05, 2008 6:50 amby bobhenry

Jiminsav wrote:thats the only way to do it.

No it taint !!!

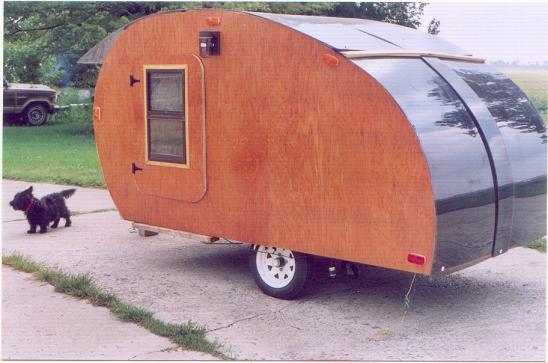

5'7" out to out

Posted:

Fri Sep 05, 2008 8:10 amby afzski

Thanks for the tips - I'm sure I'll have more questions in the future -

Bobhenry - is that a spline patch down the middle - taking up the gap of a split sheet application???? anthing special you did to make it waterproof???

Other than attaching the sheets sideways and cutting 3ft off - this was the only way I was thinking to do the skinning

Alex

Posted:

Fri Sep 05, 2008 8:27 amby bobhenry

Hell I thought it was a racing stripe

Ice dam tape

Ice dam tape it is sticky as hell you better be right on before applying it once it touches it sticks.

I figure if they use it on the roof of a $300,000 home its almost good enough for my teardrop. My lexan was screwed down with 100 % silicone at the edges as an added barrier. 1 year stored outside uncovered and zero leaks.

Posted:

Fri Sep 05, 2008 8:30 amby bobhenry

If you are worried about the 3 foot of waste don't be you have cabinets to make and galley walls to face out. You will find ways to use it

Posted:

Fri Sep 05, 2008 9:50 pmby Sam I am

I used Baltic birch ply, which comes in 5'x5' sheets. It goes on a 5' wide tear with virtually no cutting or waste. The trick is that not too many vendors have it. If you can get it, I recommend it!

Sam

Posted:

Sat Sep 06, 2008 6:06 amby asianflava

Sam I am wrote:I used Baltic birch ply, which comes in 5'x5' sheets. It goes on a 5' wide tear with virtually no cutting or waste. The trick is that not too many vendors have it. If you can get it, I recommend it!

Sam

I did that on the inside, I only cut it on one axis so that I knew the sides were parallel. The outside was 62 1/8in, I had to go with 4x8s sideways for the outside. The outside would be covered with aluminum so cheaper luan was used.

Posted:

Sat Sep 06, 2008 8:51 amby Arne

I used luan and found what gage mentioned... it is brittle.. it works, but it has to be sealed and kept out of the sun, or the top layer dries out and you get a multitude of tiny cracks/fissures.... I got some, noticed them, cpes'ed the whole t/d, and kept it out of the sun until it was primed and painted (white).. so it worked out ok, but could have been a problem...

On no. 1, I used it the long way up and over the top.. to save ply. It wasn't worth the effort. It bends quite well on the 4' side, but not well on the 8' side. When I redid the roof two years later, the stuff unsprung like it had never been bent.. plus, I had to use another piece side by side to get the 5 feet I wanted so wound up with another seam to fill.

So, the 8' side goes across, and you get some scrap that usually gets used somewhere along the way.

Posted:

Sat Sep 06, 2008 8:58 amby jplock

I have a 5 foot wide and used 2 layers of 1/8th inch Luan the second layer was offset by 12 inches so that the seam was only 1/8th inch deep on the outside layer. The two laminations were glued with panel adhesive. This has worked great for two years. The luan has proved to be better than the 1/4 inch BC plywood that was used to make the hatch door.

Luan being applied with web clamps and panel adhesive underneath and nailed to framing. This is the first layer.

On the second nail holes are puttied and sanded before being primed and painted (Notice the first offset seam up 12 inches from the bottom with extra putty sealing the seam.)

BC Plywood covering hatch it needed to be stiifer than the luan was the luan was a little to "bendy" something stiffer was needed.

Finished product not much seam exposed due to the tongue box.

jplock

P.S. The plywood was 4x8' running cross ways.

Posted:

Sat Sep 06, 2008 1:56 pmby Esteban

See if you have a hardwood supplier nearby. They sell higher quality products than big box stores. The slightly higher cost can be well worth it.

I bought birch plywood for interior paneling and 1/8" luan for the roof and hatch from one. The hardwood store luan was much higher quality than the misshapen and wavy big box store luan. It cost just a little more. It bends easily and evenly. They also had special bendy plywood which could be used for especially tight bends.

Posted:

Sat Sep 06, 2008 7:05 pmby afzski

Thaks to all for the tips - It looks I have two ways to go here - everybody has had good and bad experiwnce with either way it looks like

Alex