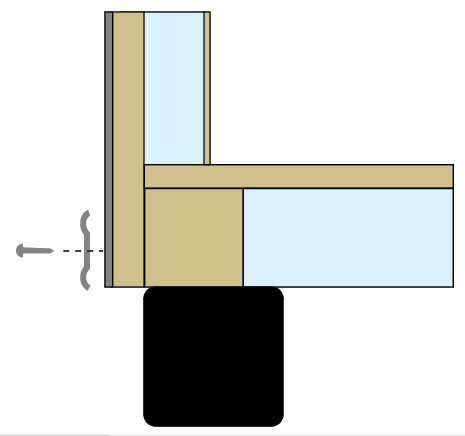

halfdome, Danny wrote:Dean, another way is to screw from the underside aluminum channel on the bottom edge of your walls with a heavy bead of your sealer in between . It gives a nice finished edge. That's the way I did my 2 tears.  Danny

Danny

That's a good idea, but I think I'm past the point where I could get channel on there.

The best I could do at this point is angle. I actually thought about using angle, but I didn't want to create a space where water could get trapped if my sealing job wasn't 100%.

I already have the original style side trim that I'll be using. Besides, you won't be able to see the bottom of the plywood unless you're laying on the ground. I'll just epoxy the heck out of the bottom edge, seal the gap between the frame and the body with goop and keep my fingers crossed.

for thinking about sealing the end grain on your plywood. I not only did the end grain but the backside surfaces of all the plywood in my tear drop. The peace of mind was worth the $ to me. Besides epoxy will store pretty well for a very long time and is a pretty handy thing to have around after the build too! I'm going to use lots of CPES on my next build.

for thinking about sealing the end grain on your plywood. I not only did the end grain but the backside surfaces of all the plywood in my tear drop. The peace of mind was worth the $ to me. Besides epoxy will store pretty well for a very long time and is a pretty handy thing to have around after the build too! I'm going to use lots of CPES on my next build.

Danny

Danny