Page 1 of 3

5x10 Plywood Source In The South NEEDED!

Posted:

Sat Jan 10, 2009 10:28 pmby TinKicker

I had brought this up within another poster's thread, but for the sake of focus on this issue, I'm doing my own thang here.

Here in Alabama every lumber supplier (even a plywood-specific manufacturer in Birmingham) looked at me cross-eyed when I asked about getting 5'x10' plywood. Nobody's got it!

Can ANYBODY recommend a source here in the Southeast I can either drive to or afford shipping from (Alabama, Georgia, Tennessee, Florida, Mississippi)on the ply?

I'm really beating my head against the wall here. It's getting so frustrating that I've started studying the fine art of biscuit joining, which I guess would be okay, but I'd rather have no seams except where I want them.

Thanks for ANY info you can send my way. Peace.

Posted:

Sat Jan 10, 2009 10:52 pmby tinksdad

I've had absolutely NO luck here in Northwest Mississippi, so I will be following this thread as well.

Posted:

Sat Jan 10, 2009 11:29 pmby madjack

...due to cost and availability, whenever I need such I just make it myself...I don't use biscuits but rather cut a slot and use a spline to join them...with epoxy...I find it to be as tough as can be and quite adequate for use on either sides or floors...at about 1/3 to 1/2 the cost...saves hair pulling as well............

madjack

p.s if you don't have a slot cutter for a router, you can use the biscuit joiner and just slide it down the work piece to make the slot...cut a spline outta hardwood and you are good togo..............MJ

Posted:

Sat Jan 10, 2009 11:54 pmby Eddielbs

When i was looking around for supplies for my build i found only one place that had 5x10 sheets of ply and it was

You should be able to find it at lumber yards that supply wooden boat builders.

Robichaux Lumber Company, Inc

2755 Highway 308, Raceland, LA 70394-3599

Contact Phone: (985) 447-7035

URL (web address):

www.robichauxlumber.com

Edit: Although i didn't end up buying the 5x10 i followed MJ's advice and spliced some sheets with a scarf type joint.. worked great for me and saved me some money..

Posted:

Sun Jan 11, 2009 1:20 amby Esteban

BoulterPlywood.com in Mass. has 4x10 and 5x10 plywood. They'll ship it to you.

Posted:

Sun Jan 11, 2009 10:45 amby TinKicker

Madjack, what's been the best epoxy you've used for joining? We just got a load of Gorilla Glue products at work, and I'm thinking about trying their wood glue.

Eddielbs, I guess I might find some boat building suppliers down around Mobile. The family's been wanting a vacation for a while...maybe sneak around and do some shopping while we're on the coast?

I'm finding that nobody in Alabama ever looks outside the 4'x8' box. Ever.

Thanks, guys for the suggestions. Either it's going to be easy or cheap, but not both.

Peace.

Posted:

Sun Jan 11, 2009 11:05 amby madjack

...

www.RAKA.com ...good folks to deal with...I really like their non-blushing epoxy with the 30min catalyst...a good waterproof wood glue, such as, Gorilla or TiteBond II/III would probably do as well, I just really like the epoxy for making as fool/break/goof proof a joint as possible and with epoxy, you need minmal clamping pressure...just remember that "cheap" does not necessarily mean quick or easy...............

madjack

Posted:

Sun Jan 11, 2009 11:34 amby schaney

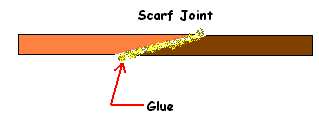

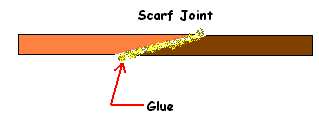

TinKicker, another way to make plywood sheets any size you want/need is using a scarf joint. I normally use an 8:1 ratio.

Photo courtesy of Duckworks Magazine

Photo courtesy of Duckworks Magazine

Article on

Scarfing Joints

Gluing the joint with epoxy, it will always be stronger than the surounding wood. I like and use West Systems epoxy.

Posted:

Sun Jan 11, 2009 6:30 pmby Toytaco2

I hope this doesn't high jack the thread, but, how do you ever get the scarfed edges of plywood flat/parallel enough to glue them up?

Posted:

Mon Jan 12, 2009 9:29 amby TinKicker

Thanks, Madjack and Schaney. Raka's right next door in Florida too! I guess it's time to get epoxy-smart.

The only scarfing I've ever done is at the supper table...but I'm willing to try new things.

Posted:

Mon Jan 12, 2009 10:28 amby schaney

Yes, scarfing isn't just for the dinner table anymore

The fancy way to make scarf joints is with something like a West Systems saw attachment

I don't have one yet so

- I mark my 8:1 ratio line

- stagger the sheets

- clamp them to the table

- use a hand plane to rough cut the scarf

- then finish it with a belt sander

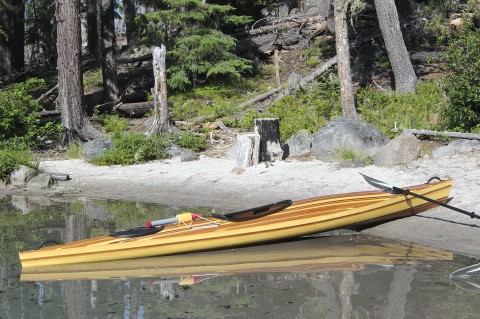

You can use scarf joints on plywood and solid wood to make what every size piece you need. If you look closely you can see were the side panel on my kayak is scarfed just in front of the seat and the solid wood trim on the top edge by the front deck

Posted:

Mon Jan 12, 2009 12:32 pmby TinKicker

That makes it very clear, Schaney. And that's a VERY good looking kayak. I wasn't able to really picture an effective scarf joint until I saw the wood you used. This project is a first for me in that the only plywood I've every worked with is the nasty construction type. Cutting that stuff at an angle just makes splinters and notches. But I understand now, and thanks.

Posted:

Mon Jan 12, 2009 6:46 pmby schaney

Glad to help. I normally work with Marine grade Okoume or cabinet grade baltic birch plywood.

Thanks for the compliment on my kayak. That's my basic, kick around one, here is my fancy woodstrip one.

Posted:

Tue Jan 13, 2009 12:33 amby TinKicker

That is one beautiful boat! I imagine that kind of skill took many years to gain. Have you built many boats?

Posted:

Tue Jan 13, 2009 9:52 amby schaney

Thanks, so far I've only built a couple of small boats, but have plans of doing more.

I've been tinkering and building stuff since I was a kid and have a fair amount of metal/woodworking skills and knowledge. On the woodstrip I learned the process by building a small test panel and doing some research, then I just jumped in. I'm very happy with the results and glad it performs as well on the water as it looks.

You should be able to find it at lumber yards that supply wooden boat builders.

You should be able to find it at lumber yards that supply wooden boat builders.