Opinions needed on Hatch Ribs

I have decided to go with wood for the hatch frame instead of steel tubing for a few various reasons and that has brought up a question:

Which is better?

Hatch ribs from 3/4" ACX plywood or buying some 1x8s and use solid wood and if solid wood, what kind?

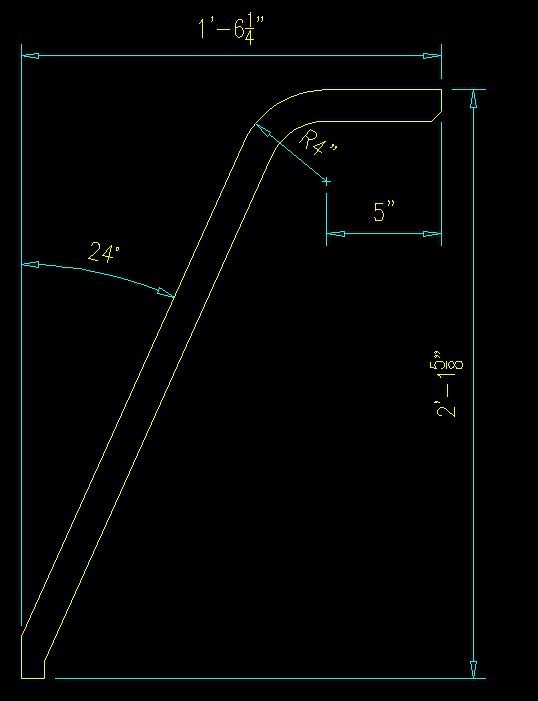

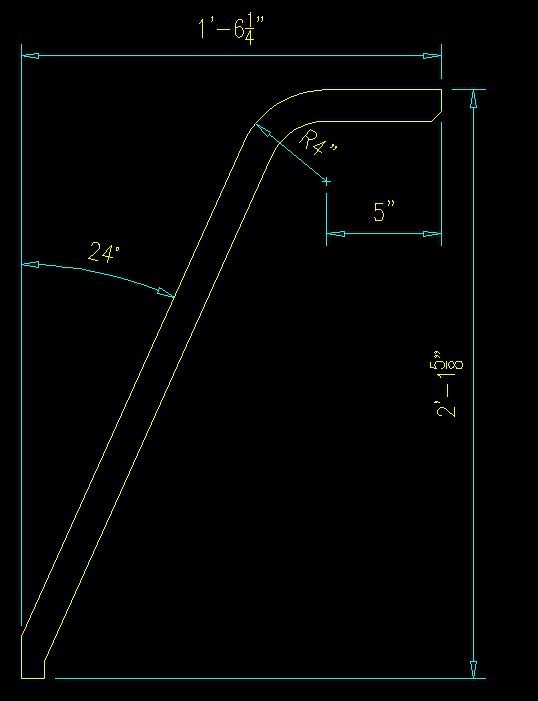

My ribs are going to be about 30" or so overall length and 1 1/2" deep.

What say you?

Which is better?

Hatch ribs from 3/4" ACX plywood or buying some 1x8s and use solid wood and if solid wood, what kind?

My ribs are going to be about 30" or so overall length and 1 1/2" deep.

What say you?