john wrote:I widened my axle without changing the frame. The original axle was something like a 1x1 square tube. The replacement was a 3500lb round tube type axle 3" or so in diameter. I used 500 or 750 pound leaf springs.

I agree that this can be a valid approach, because the axle which has a 3500 lb capacity with a normal overhang (of the hubs beyond the springs) might still have enough capacity after the increase in overhang. That's very different from extending the original barely-adequate axle tube to have more overhang.

When going to a higher-capacity axle, I think it's important to still select springs to suit the actual load, as John has.

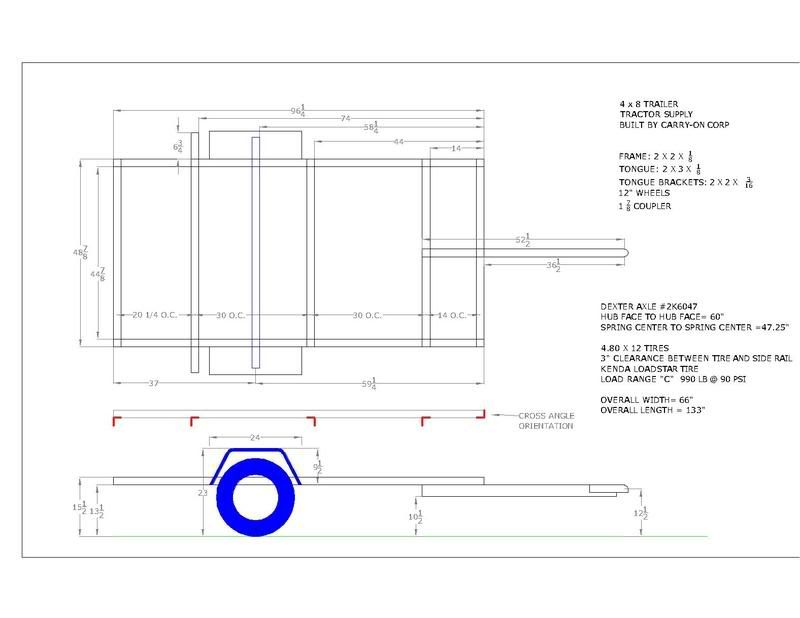

My travel trailer has a 3500 lb axle (equivalent to a Dexter D35) which specifically allows a maximum of 9" per side of hub overhang past the springs... and the trailer's original design is already right out at that limit.

By the time one of these generic base trailers has had the axle replaced, or the axle and frame modified, I personally don't see any value in having bought the trailer in the first place, instead of just buying the right one or having one made to suit.