Bracing question ... honeycomb?

I started my initial build design thread HERE.

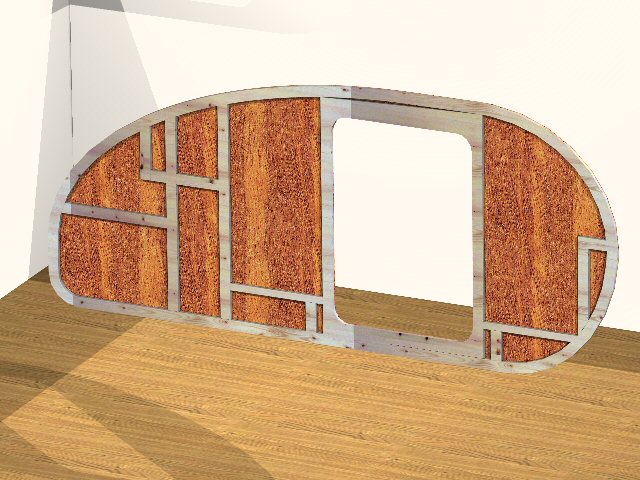

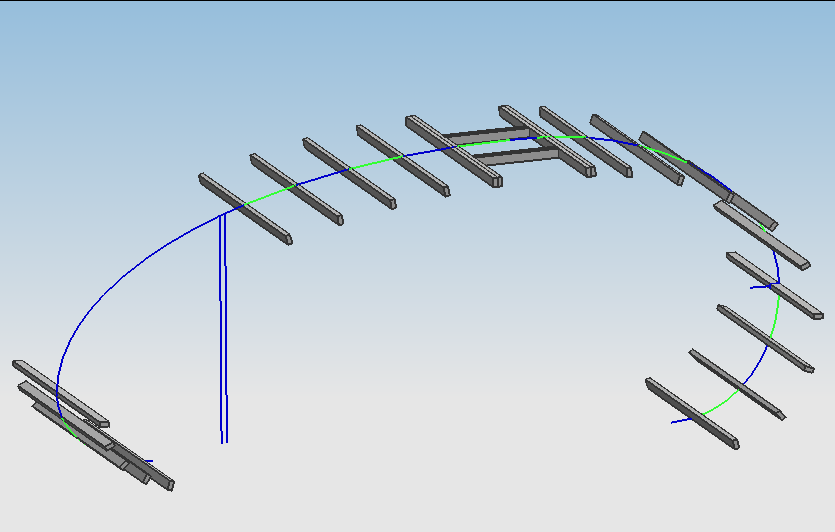

You can see the proposed bracing in the pictures (it's the highlighted areas). Later on in the thread, I start to wonder about using cardboard honeycomb in the walls in lieu of bracing.

There will still need to be traditional bracing for the windows/door, right?

Where could I get some of that cardboard honeycomb stuff?

I'm thinking that the addition of the honeycomb will act just like a hollow-core door.

Ideas, suggestions?

You can see the proposed bracing in the pictures (it's the highlighted areas). Later on in the thread, I start to wonder about using cardboard honeycomb in the walls in lieu of bracing.

There will still need to be traditional bracing for the windows/door, right?

Where could I get some of that cardboard honeycomb stuff?

I'm thinking that the addition of the honeycomb will act just like a hollow-core door.

Ideas, suggestions?