Cabinet Question

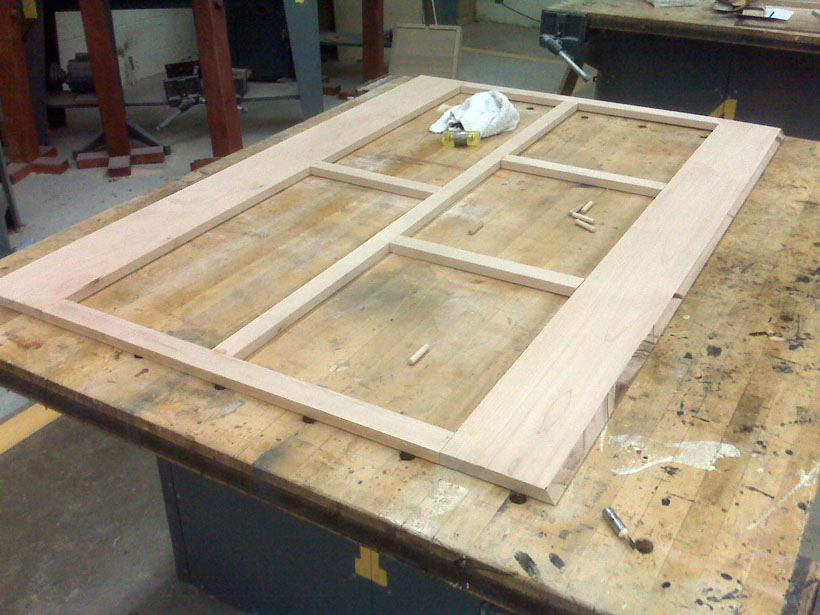

I've made a faceplate for the cabinets at the front of my tear but now need to decide how to attache the cabinet walls.

I'm considering routering a grove in the faceplate for the cabinet walls and the floor of the top cabinet. I'm using 1/4 oak plywood for the walls and floor.

Is this the best approach? What other options would work?

I'm considering routering a grove in the faceplate for the cabinet walls and the floor of the top cabinet. I'm using 1/4 oak plywood for the walls and floor.

Is this the best approach? What other options would work?