Trouble with Polyester resin

We finished Thypod back in July last year, and had some great fun camping out in it. We didn't know when we built it, that polyester resin was porus  , and noticed some cracking in the resin shortly after having it campable.It seemed worse on the top at the front of the trailer.

, and noticed some cracking in the resin shortly after having it campable.It seemed worse on the top at the front of the trailer.

I gave the affected area a good coating of gel coat , thinking that would sort the problem out.

We covered the trailer over winter,but after it's first outing this year, I noticed more cracking, and some bubbling almost like blisters in the resin.

Further investigation showed a large area of the ply was damp under the resin, so I decided the best action would be to replace the ply , and cover the trailer with aluminium.

Here's the photos;

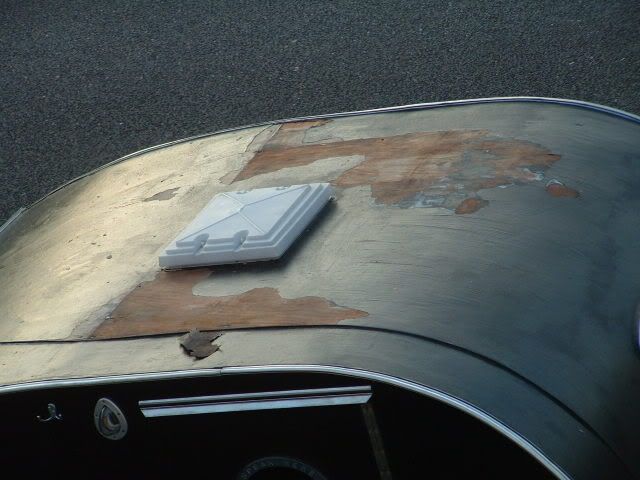

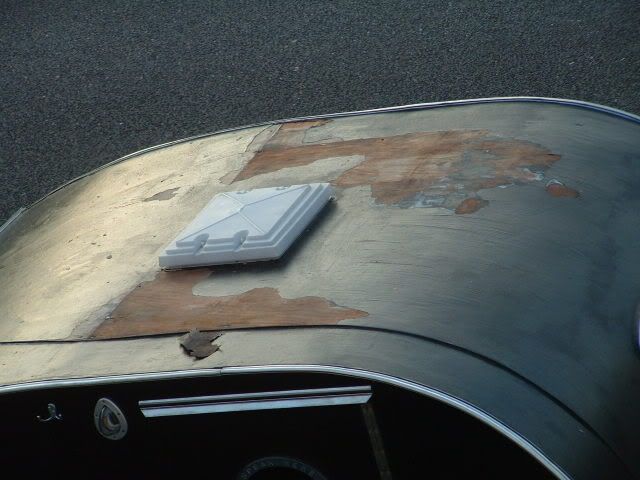

Cracking in the resin

The affected area;

On removing the ply, we found water on the insulation

We ended up removing the whole roof;

Here's Rosie gluing up for recovering

Heres thypod stripped , with its new roof, awaiting the ali skin.

I fixed a 3/4" batton along the bottom, and then a wider piece of timber under that to sit the ali on and make things a bit easier.With the batton removed I could dress the bottom edge of ali around the bottom edge of the trailer;

I bought a 35' long roll of 8' wide ali, there was a mix-up with the price, and I got it for £200. It's .032" or .8mm thick

It's not the easiest thing to work with;

Heres our 8' wide teardrop;

Perhaps we could have a built in porch;

The plasma cutter made light work of it ;

Removing the guide baton

We couldn't resist seeing what it's going to look like polished up;

Here's a view from the top, before we fitted the roof vent

Heres the rear hatch hinge refitted .I've still got a bit of finishing off by the number plate and the rear lights

The doors have new stainless steel hinges . The ali has been dressed around the doors , and into the returns;

It was dark by the time we finished for the day;

I'm planning on polishing the ali before fitting the trim and weather stripping.

I'm feeling confident the damp is going to stay out now

I think it should be done for our gathering later this month

I should have done it first time around, but we live and learn.

Dave

, and noticed some cracking in the resin shortly after having it campable.It seemed worse on the top at the front of the trailer.

, and noticed some cracking in the resin shortly after having it campable.It seemed worse on the top at the front of the trailer.

I gave the affected area a good coating of gel coat , thinking that would sort the problem out.

We covered the trailer over winter,but after it's first outing this year, I noticed more cracking, and some bubbling almost like blisters in the resin.

Further investigation showed a large area of the ply was damp under the resin, so I decided the best action would be to replace the ply , and cover the trailer with aluminium.

Here's the photos;

Cracking in the resin

The affected area;

On removing the ply, we found water on the insulation

We ended up removing the whole roof;

Here's Rosie gluing up for recovering

Heres thypod stripped , with its new roof, awaiting the ali skin.

I fixed a 3/4" batton along the bottom, and then a wider piece of timber under that to sit the ali on and make things a bit easier.With the batton removed I could dress the bottom edge of ali around the bottom edge of the trailer;

I bought a 35' long roll of 8' wide ali, there was a mix-up with the price, and I got it for £200. It's .032" or .8mm thick

It's not the easiest thing to work with;

Heres our 8' wide teardrop;

Perhaps we could have a built in porch;

The plasma cutter made light work of it ;

Removing the guide baton

We couldn't resist seeing what it's going to look like polished up;

Here's a view from the top, before we fitted the roof vent

Heres the rear hatch hinge refitted .I've still got a bit of finishing off by the number plate and the rear lights

The doors have new stainless steel hinges . The ali has been dressed around the doors , and into the returns;

It was dark by the time we finished for the day;

I'm planning on polishing the ali before fitting the trim and weather stripping.

I'm feeling confident the damp is going to stay out now

I think it should be done for our gathering later this month

I should have done it first time around, but we live and learn.

Dave