8 wrote:It's all leverage. 85 pounds could easily exert 300 pounds of pressure when the hatch stick straight out.

I interpret your wording to say that the force exerted at the attachment point of your hatch strut is 40 pounds. If that is the case, either you have a really light hatch or the attachment point is far away from the hinge. But then you would need a strut with a lot of travel.

I thought I read somewhere you can get the force applied by the mounting point by attaching a stick there pointing down and let the weight press against a bathroom scale located about where the other end should attach. Most likely, the value will change based on how far open the hatch is and the more it is horizontal, the more force needed to hold it open.

8, welcome to the forum! I hope you find lots of useful information and people on here like I have!

I did exactly what you talked about in your post. I took a piece of scrap and placed it under the hatch approximately where I wanted to mount the spring. It ends up being about 20" out from the hinge. The other end on a bathroom scale read about 40lbs.

I don't think that a hatch could ever exert more linear force that it actually weighs. I will agree that a 85 lb hatch could probably exert 300 ft-lbs of torque (twisting force) acting directly on a pivot point.

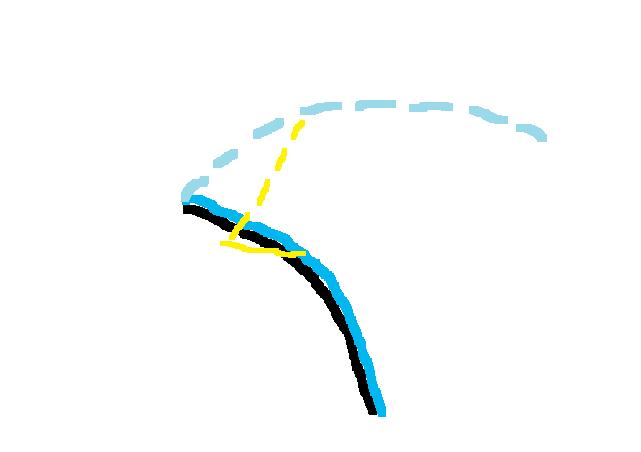

I think I know my problem. I've been calculating linear force as if the spring were stationary and simply lifting the weight upward. In fact, the spring will be mounted so as to face down/out first.

It will press outward on the harch attachment point and require significantly more force to raise the hatch by applying force in this direction. Duh!

Please forgive the crudeness of the drawing, it's the best I can manage on my laptop with Paint.

This would explain why folks like Rob and Planovet got good results with the larger capacity springs. Thanks for talking me through it everyone! I think I'll give the 125lb springs a try and see how that works.

Brad