Page 1 of 2

Routing wires under the trailer.

Posted:

Tue Nov 24, 2009 11:13 amby Looneytoons

This is such a basic question I'm almost embarrased to ask it. However, my trailer frame is a little different than most of the ones I've seen here.

In addition to the trailer light wires, I will also have the 12 volt wire from the battery on the tongue.

My trailer frame is welded from 2 1/4" tubing, so there is no channel into which I can insert the wires or conduit.

Shoud I:

1) Just staple the wires to the bottom of the 3/4" solid plywood floor; routing the wires under the tubular cross members?

2) Screw 1/2" PVC conduit sections to the bottom of the floor between the cross members; routing the wires under the cross members without conduit?

3) Add 2 1/4" spacers to the bottom of the floor and route the conduit the full length from the tongue to the rear of the frame.

4) Do you have a better suggestion that I haven't thought of?

I do intend to add insulation under the floor.

As always, thanks for your help!

Posted:

Tue Nov 24, 2009 11:19 amby planovet

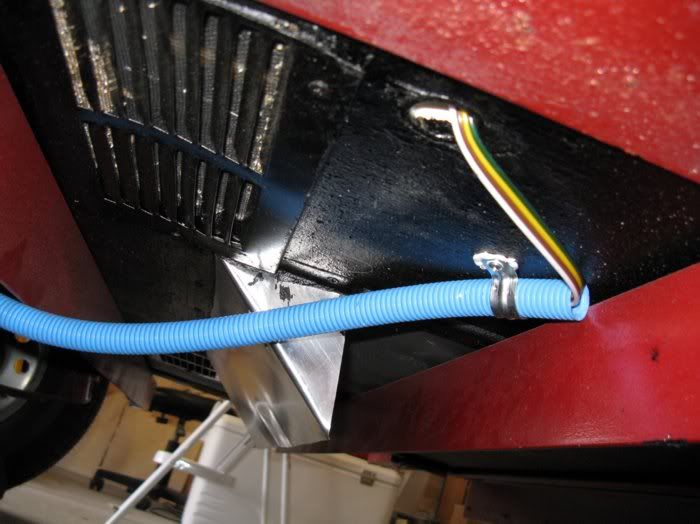

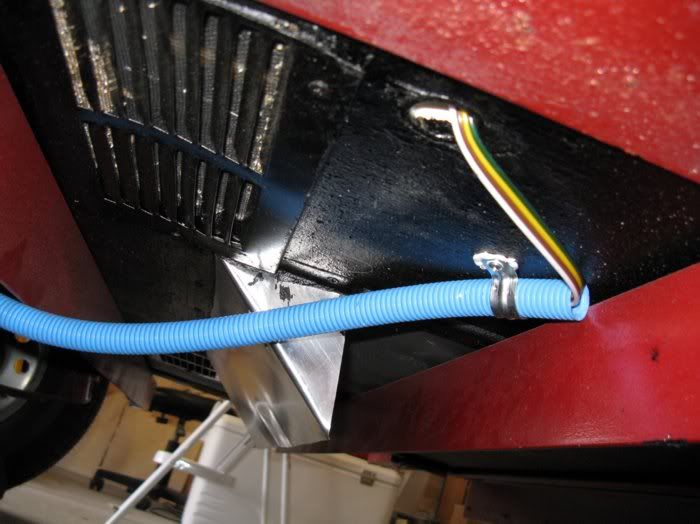

I used blue flexible conduit that I got from Lowes. It worked great for my application. The pictures show just one but I eventually ran 2 lines, one for 12V and one for 120V.

Conduit link

Posted:

Tue Nov 24, 2009 11:23 amby ajricher

The flexy stuff is nice but always looked untidy to me. I've used the grey PVC "rigid" conduit in trailers to good result - with the boxes and all it's easy and cheap to do what amounts to a waterproof wiring job, feeding out the back of the box through the floor as needed.

Alan

Posted:

Tue Nov 24, 2009 11:29 amby madjack

...if using the PVC conduit, you can use a hair dryer(on high) or heat gun to warm and soften it so you can strap it to the floor and bend it around the crossmembers...becareful about getting it "too" hot...it will melt or sag making it hard to get your wire thru it.............

madjack

Where's the wires?

Posted:

Tue Nov 24, 2009 11:29 amby eamarquardt

On my dump trailer (see album) I used watertight flex conduit. The wiring will outlast me by several genarations.

On my tear, I used 2X3 tubing and plan to run the wires inside the tubing. I'll used electrical fittings to protect the wires as they enter and exit the tubing. You can drill a 1 inch or so hole in the sidewall without significantly affecting the strenght of the tubing but I wouldn't drill into the top or bottom as that would weaken it (but probably not enough to matter.

Hope this helps.

Cheers,

Gus

Posted:

Tue Nov 24, 2009 3:11 pmby jplock

I used plastic tie wrap mounts and tiewraps along the frame, then when finished the wire bundle was sprayed with automotive undercoat spray. When completed it blended in with the black asphalt roofing tar that had been applied earlier to seal the bottom wood. My trailer is about 3 years old and the wiring has worked good.

jplock

Posted:

Tue Nov 24, 2009 3:11 pmby Arne

I used plastic plumber strap cut in short pieces so there were two holes in each piece. I spaced them every 12" and screwed them to the bottom of the floor with the wire between the screws.... where the wire passed through the x members or any metal part of the frame, I put caulk in the hole. After the caulk hardened, the wires could not move and rub against the metal frame.

When I used zip ties to hold the wire to the frame, I did the same thing with caulk... everything is solid, no wire movement.

My minor opinion is that the bottom of the frame is probably the least likely area to have a wiring problem if done right....

Posted:

Tue Nov 24, 2009 4:11 pmby Corwin C

IMHO - Any wire routing will be fine as long as it is protected from road debris, sharp areas on the frame (watch for those "pinch points") and secure. The less movement in the wiring, the better. Also, make sure all connections are sealed up tightly to prevent water getting in and starting corrosion.

Personally, I try to run mine inside the frame when possible.

Corwin

Posted:

Tue Nov 24, 2009 4:39 pmby Geron

A grey "flexble" conduit is available at HD. With the connectors/boxes you have a water tight system with the wires protected. Any terminal end was filled with Caulk. That's what I used.

Posted:

Tue Nov 24, 2009 4:39 pmby asianflava

I screwed these strain reliefs directly to the frame and zip tied the wire to it. I left the wire exposed in case I needed to add or troubleshoot a wire. A good automotive wire should be weather and UV resistant.

Posted:

Tue Nov 24, 2009 7:42 pmby jplock

Here are some pictures of my frame wiring after 3 years and approxamately 20,000 miles

I hope this helps! It has worked good for me.

jplock

PS below link is more wiring pictures

http://www.mikenchell.com/forums/album_personal.php?user_id=2148&sort_method=pic_time&sort_order=DESC&start=120

Posted:

Tue Nov 24, 2009 10:00 pmby bfitz

A related question: What do people do to get propane back to the galley? It seems a bit dangerous to leave a hose exposed underneath, and I'm very very leary to run it inside.

Posted:

Tue Nov 24, 2009 10:55 pmby Dale M.

bfitz wrote:A related question: What do people do to get propane back to the galley? It seems a bit dangerous to leave a hose exposed underneath, and I'm very very leary to run it inside.

You can run it in rigid piping (maybe 1/4 inch steel) or maybe soft drawn copper tubing..... And yes, you should NOT run it inside..........

Dale

Posted:

Tue Nov 24, 2009 11:02 pmby satch

Another note, to those useing "zip" ties to hols up your wires, check them regularly, after time they can get brittle and break.

Posted:

Wed Nov 25, 2009 9:39 amby Arne

All connections should be checked periodically... zip ties are prone to uv destruction... under a trailer, out of the sun, they should last years. or I should say, mine have.