I have a 5'7" out to out wide teardrop on a modified HF frame and I will give you my spin for what it is worth.

You are asking 3/4 "

(Think of that 1 1/2" x 1 1/2 " "2x2" cut 1/2 way thru for a lap joint)

of white pine to support the entire weight of the sides and roof and anything fastened to them in a 1 foot cantilever situation.

Your effort to save weight is commendable but this just ain't the place to do it.

On a harbor freight trailer the fenders and wheels stand 2 1/2" or more proud of the frame. There are 2 ways to handle this, bump ups or a deeper (and higher) floor. Even a 7/16 floor will require 16" on center support ( yes you can get by with less because you are dispersing the load over a mattress ) MAYBE ?

Mine had bump ups that measured 2 1/4 inches. Even with a serta pillow top mattress I only slept in it one trip with the bump ups under the mattress. They telegraphed thru and were uncomfortable so after the fact I added more weight by adding blue foam to level with the bumpup and a 7/16 sub floor over top. This proved to be a great way to insulate the floor and I do no regret doing it but if I had it to do again......

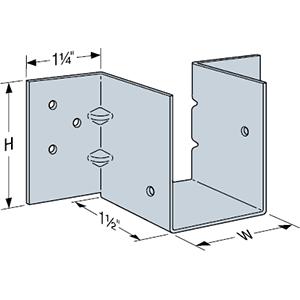

I would rip 2x4's to 3" and stand them on edge 2' apart. The 1/8 could still go on the bottom except at the wheel wells. Install insulation in all cavities for an insulated floor and top with 1/2" plywood minimum glued and screwed 4" on center. The addition of a rim board at each side will afford a place to fasten the exterior sides to. There are several styles of steel joint reinforements that will help strengthen the connection of your floor joist to the perimeter ribbon.

This is the foundation to your house it recieves the shock of each and every pot hole and lump in the road I would not choose to make this the place to save weight. Build this as a torsion box and black goop the bottom and then install it with 6 to 8 carriage bolts directly thru the 2x3 and into the frame. and double nut the connections for safety.

We are in the snow belt and need an insulated floor to extend our camping season. The folks in Florida and sunny california do not see our need but this works. Take a moment and start at the rear of my album and page forward 3 or 4 pages and see how a bent and damaged $75.00 HF frame can be used for a tear.

From a guy that has been there and done that for what it is worth !