sealing and aligning the hatch

Hi All,

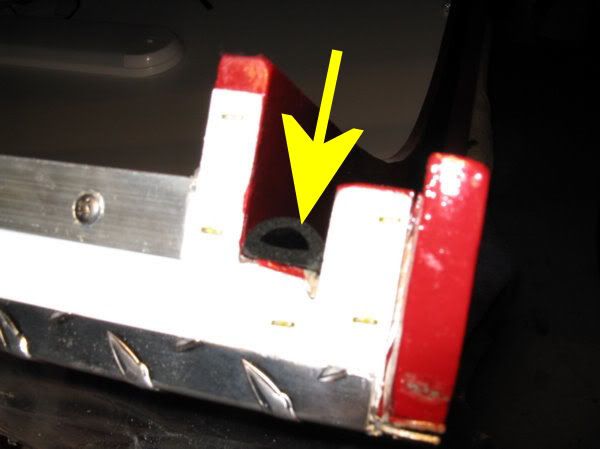

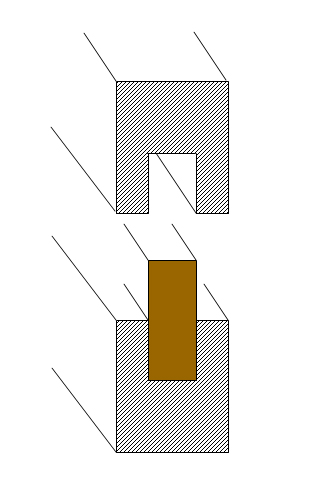

Been a long winter, but I survived. No progress on the tear until lately. A question: Are there drawbacks to using the following set up to seal the hatch and align it when closed?

It seems like it would be easy to construct, durable, and weatherproofish.

Not shown:

Round-overs on the top of the spline to ease closing.

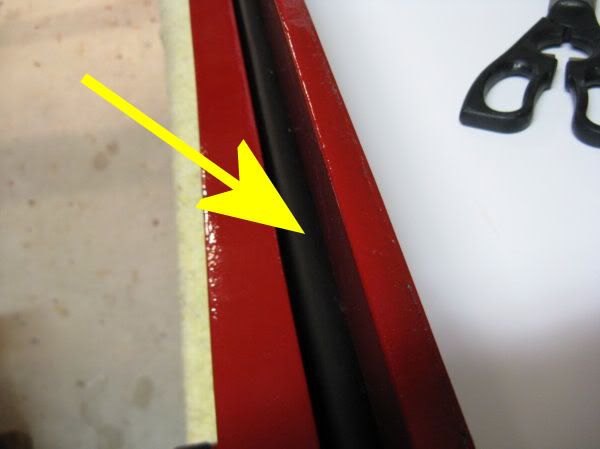

Rubber gasket inside the upper dado to make weather tight.

Thanks,

Brian

Been a long winter, but I survived. No progress on the tear until lately. A question: Are there drawbacks to using the following set up to seal the hatch and align it when closed?

It seems like it would be easy to construct, durable, and weatherproofish.

Not shown:

Round-overs on the top of the spline to ease closing.

Rubber gasket inside the upper dado to make weather tight.

Thanks,

Brian