Page 1 of 2

Question about roof spars?

Posted:

Wed May 05, 2010 12:02 pmby mlsa

Well I'm getting excited. Friday I go pick my two windows up I bought off Ebay. They were here in Houston so I saved shipping charges. While I'm gone I'll go get some of the wood for the striping I'll do.

I do have a couple of questions for you gals/guys.

(1) For your roof spars do you use 1"x2" or 2"x 2" or something else?

(2) Has anybody ever used paneling instead of plywood for the roof?

I tried using the seach to find answers but with no luck. I know I saw somewhere once about the roof spars but can't find it now. I'm still a ways from putting up the roof but like to get all my info up front.

Thanks for any help you can give.

David

Posted:

Wed May 05, 2010 12:25 pmby planovet

I used 2x4s that were ripped down to fit the depth of the notch that I cut. After the ceiling was laid in, I measured and cut to fit. It turned out to be a tad larger than a 2x2.

I used a paneling-like product for the interior ceiling. But for the roof I used baltic birch ply.

Posted:

Wed May 05, 2010 1:00 pmby Endo

I use 1x2's for roof spars. Some areas get a double or triple 1x2 glued together (hatch hinge area).

Posted:

Wed May 05, 2010 1:19 pmby aggie79

I used single 1x2s (poplar) at 12" on center. Doubled 1x2s were used at the roof vent, galley bulkhead, and where the exterior plywood would be butt-jointed.

Posted:

Thu May 06, 2010 12:11 pmby chorizon

aggie79 wrote:I used single 1x2s (poplar) at 12" on center. Doubled 1x2s were used at the roof vent, galley bulkhead, and where the exterior plywood would be butt-jointed.

That's how I did mine...

Posted:

Fri May 07, 2010 6:32 amby Jst83

Went 2x4 ripped in half on the first, going 1x2 on the second as others have stated with thicker for the roof vent and hatch hinge. Wish I'd gone smaller on the first I would have saved a bunch of weight on mine as I went with 2x2 walls also. It's a rolling framed house

Posted:

Fri May 07, 2010 7:24 amby bobhenry

I cut southern yellow pine from #1 grade 2x12's into 2x2's

( 1 1/2" x 1 1/2" )

The SYP is about 50% stronger than the spruce pine fir grade.

They were spaced 12" on center.

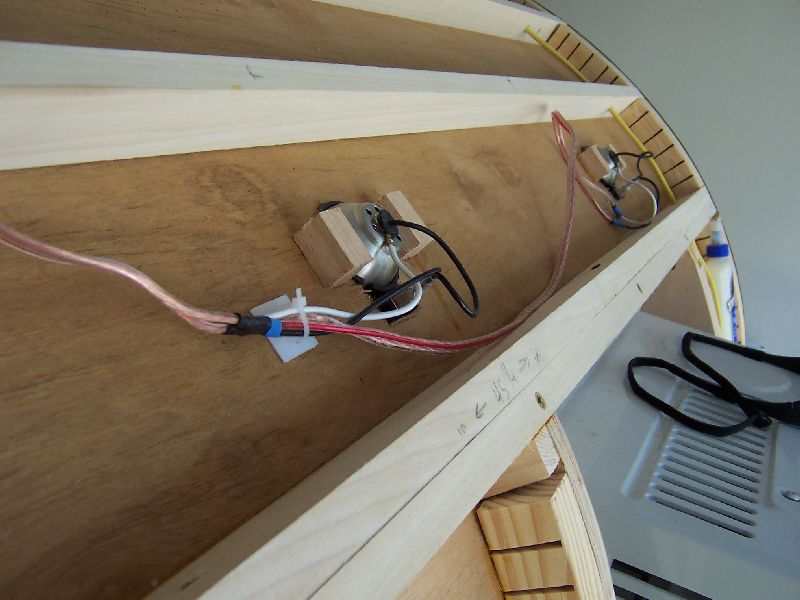

I rabbetted the ends to fit a notch in the sides as you can see in the pics.

Posted:

Sun May 09, 2010 9:20 amby dh

I'm doing similar to BH, couldn't find a single straight 1x2 so I'm making my own. I got a 2"x12"x12', and had them cut 2 pieces out of it 62" long (my interior width) so I just have to rip my spars. Also, you don't have to double up any spars, just rip a 2x2.

Posted:

Sun May 09, 2010 9:27 amby prohandyman

dh

Sometimes cutting a 2x into strips will release stored tension in the grain where the moisture was dried, and the now cut pieces will curve and warp as they come off the saw. Just my experience!

Posted:

Sun May 09, 2010 9:31 amby madjack

I used1x2 oak on the first one and ripped 1.5" strips offa sheet of 9ply 1/2" plywood and glued up doubles for the second resulting in 1x1.5" spars...doubled around the vent opening for additional screw area and used a 2x2 piece of white oak for the hinge spar...has worked quite well for me....................

madjack

Posted:

Sun May 09, 2010 11:07 amby regis101

I only have one build. 2 x 2 was used for the spars. I did consider the weight issues but think it was offset by the strength and surface joining area as compared to a 1 x 2.

Posted:

Sun May 09, 2010 11:20 amby parnold

I used 2 x 2. I figured it gave me twice the width to make sure my screws hit something.

Posted:

Sun May 09, 2010 7:14 pmby bobhenry

prohandyman wrote:dh

Sometimes cutting a 2x into strips will release stored tension in the grain where the moisture was dried, and the now cut pieces will curve and warp as they come off the saw. Just my experience!

If you cut 12 cut 3-4 extra because Dan is right grain relaese is rather unpredictable. I had one that thought it was a horseshoe in a previous life. It seem that if the end grain doesn't have a smile ( circular grain pattern) they were cut closer to the heart of the tree and are more stable.

Posted:

Mon May 10, 2010 10:46 amby LMarsh

I've done 3 builds and used 1x2's for all three. I used more spars than what looks like most people posted here have used. I glued the ends to the inside wall and then drilled and screwed from the outside. At the roof vent I framed it with 2x2's for extra strength and to have a wider board to work with when attaching the vent and such. I also used a double 1x2 popular at the galley hinge. Pretty much standard design from the Benroy plans available here.

I don't think I'd use paneling on the actual roof, but I suppose for a budget teardrop it would work fine. I always go for maximum waterproofing and also whatever materials will be the best if water does leak in. To me it seems after all the work you put into building a teardrop you might as well spend a little extra on quality materials that will last for the long term.

Too bad pretty much every consumer product you buy now a days is junk no matter what you spend on it. No one cares about quality, just low price. Can't say I'd want my teardrop to be made with the cheapest materials I could buy. Just my 2 cents.

Lucas

Posted:

Tue May 11, 2010 2:41 amby dh

My shop teacher had a saw blade with a hickory board "clamped" to it on the wall, along with the three belts that got burned up. It had marks from where they tried to pry it open and save the blade.