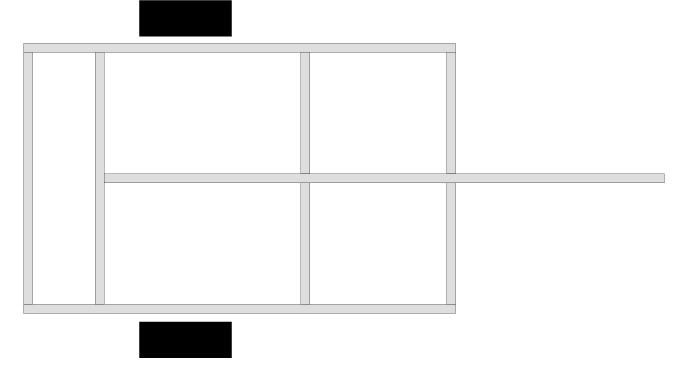

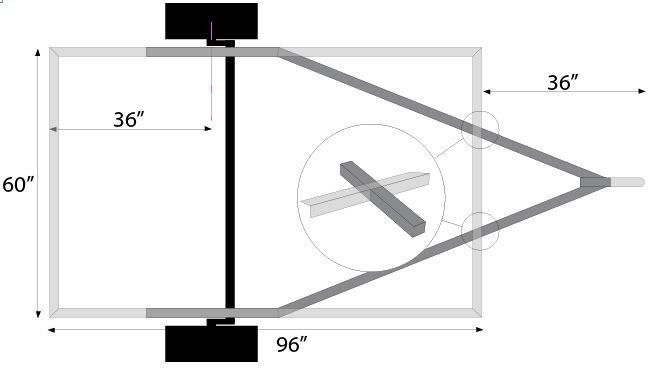

MisterGraphic wrote:Would it be wrong to "notch" the front angle

where it meets the tongue?

Either notching the angle or just cutting it either side of the tongue is OK - and cutting it means you can keep the top of all parts level with each other.

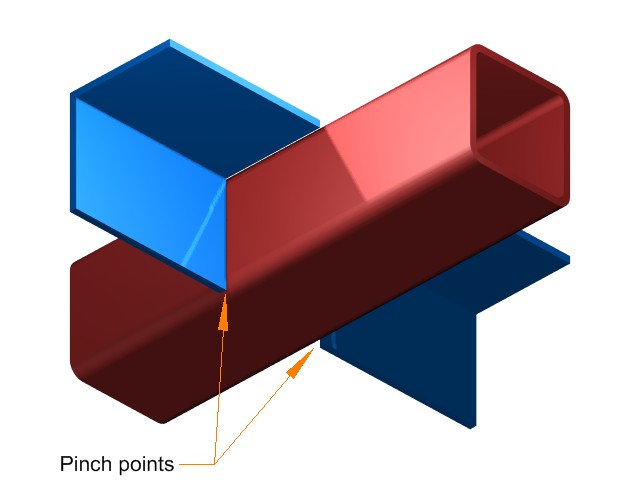

The one problem that this raises is a nasty 'pinch point' where the stiff toe of the angle hits the equally stiff bottom face of the tube.

To visualise this, think of the red tongue tube held rigidly and now you pull down on the ends of the two blue angles - you will see that the downward leg of the angle is trying to crush the tube and because it is pressing on the flat sides, they don't have much resistance until you get right to the bottom where the bottom face of the tube makes it very strong. So all the bending load is being concentrate into those two little spots shown by the arrows and one day they will start to crack.

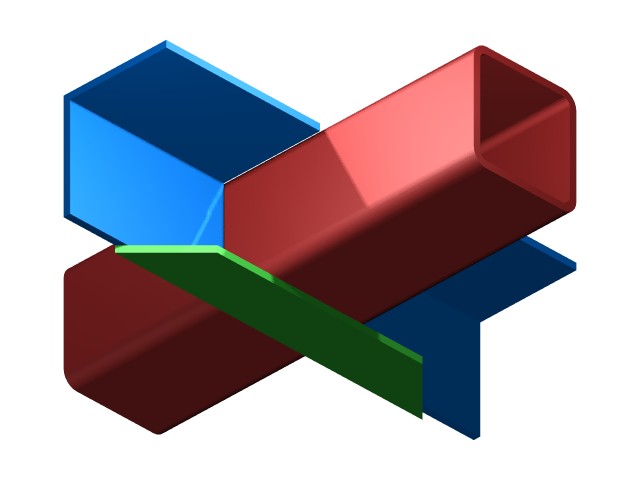

A simple solution is to weld a small bit of flat bar across the two toes as shown in green below.

Believe it or not, but this would be better if it is

not welded to the red tongue tube but just to the two blue angles. This is because a fillet weld running across the tongue tube at this point would put a stress in the tongue that would weaken it, and again a crack may one day start there.

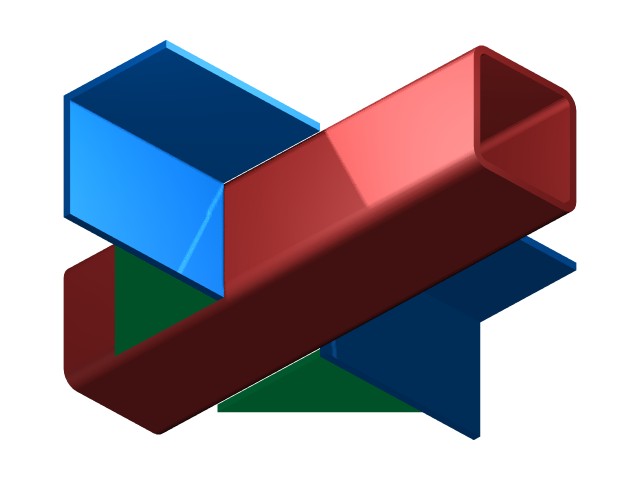

I missed wimperdink's comment about little triangles - these would be just as goiod and I assume he means something like this:

In this case, welds to the toingue tube are no problem as they are along its edge, not across its bottom face.

You know a man is on the level if his bubble is in the middle.

You know a man is on the level if his bubble is in the middle.

Mark (& Cindi)

Mark (& Cindi)