Page 1 of 2

Best way to orient 4x8s ?

Posted:

Mon Mar 28, 2011 8:13 pmby TBuilder

So I want a 5+' tall benroy. The question is, whether it is better to join the plywood sheets, then stand them up side-by-side or one on top of the other?

Too bad I just can't buy a 5x8 piece of plywood. :thinking:

Posted:

Mon Mar 28, 2011 8:39 pmby eamarquardt

Why can't you buy 5' high plywood. 5X9 (and 5X10) should be available if you look around.

Cheers,

Gus

Posted:

Mon Mar 28, 2011 10:44 pmby Pizzaguy

You could just do what I did. Join 2 different species together to get to 5' (even thou mine is only 4' high)

Directions are in Steve Frederick's shop manual available here....

http://www.steve-frederick.com/shopman05.html

Posted:

Mon Mar 28, 2011 11:22 pmby atahoekid

I have the same issue. Sheets out of the ordinary 4x8 tend to be a bit pricey, so I am planning on stacking them and staggering the joints. The eight foot length will run the length of the TD. No particular reason other than I think that'll be easiest. If anyone has any structural reason to do otherwise, please let me know.

Posted:

Tue Mar 29, 2011 12:19 amby Dusty82

I called a local lumber yard to check into a sheet of 5X9 3/4 inch ACX to do a trailer floor. I just about fell on the floor when the guy on the phone told me it was $110 per sheet. A sheet of 4X8 is only $30 locally. I figured it would cost a bit more, but not over triple the price! No thanks - I'll look at the joints with pride...

EDIT: And I agree - stack them one atop the other.

Posted:

Tue Mar 29, 2011 3:33 amby Lgboro

A biscuit joiner (aka plate joiner) works really well joining two pieces of wood, although a good plate joiner is fairly expensive initially ($150 or so for a name brand). They are easy to use and make a strong and almost invisible joint is properly done.

Posted:

Tue Mar 29, 2011 5:37 amby TBuilder

Thanks for all the replies. I'll shop around for a 5x9 some more, and if I can't find anything affordable, I'll just stack 2 on top of one another.

Posted:

Tue Mar 29, 2011 6:37 amby bobhenry

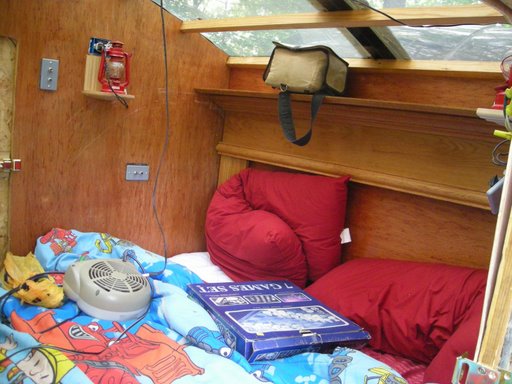

I guess I am the odd man out. My sides were oriented vertically. I planned for one seam to fall at the galley wall and the second to break at the edge of the door. This allows the galley wall and the internal reinforcing at the doors edge to "connect" the sheets.

To stiffen the 3 panels I added a continuious 1x4 at the floor. This carries the weight of the wall and stiffens the ,now giant, panel.

This 3/4 inch void afforded me a place to run the electrical and a cavity for insulation.

Note the nest of wire at top right of the pic

Posted:

Tue Mar 29, 2011 7:32 amby CARS

There is a wonderful sticky on this subject near the top of the Construction Tips and Techniques page:

http://tnttt.com/viewtopic.php?t=34381

I bought my ply, bought a router, and bought 4 1/2"x10' pipes yesterday. I will add my regular 4' pipe to them to get the clamps long enough to make 10' panels. (hopefully this weekend!)

Posted:

Tue Mar 29, 2011 7:57 amby TBuilder

CARS,

Yeah, I read that thread earlier, got some good ideas from there. I've been lurking for a while, and I try to search before asking questions. These campers have been around for decades, with a very strong "custom" slant towards them, so chances are whatever I come across has already been discussed/solved before.

Posted:

Tue Mar 29, 2011 8:59 amby CARS

TBuilder wrote:CARS,

Yeah, I read that thread earlier, got some good ideas from there. I've been lurking for a while, and I try to search before asking questions. These campers have been around for decades, with a very strong "custom" slant towards them, so chances are whatever I come across has already been discussed/solved before.

Sorry about that. I got off topic along with the other posting about routing a spline to join the sheets. My mind wanders once in a while.

I am building a 4' x 10', so I am just going to add 2' to the short side. This birch ply I picked up was advertised as 7 ply, but ends up being 11 really thin plys... Hope that's a good thing...

Posted:

Tue Mar 29, 2011 11:43 amby planovet

Posted:

Tue Mar 29, 2011 11:57 amby planovet

CARS wrote:This birch ply I picked up was advertised as 7 ply, but ends up being 11 really thin plys... Hope that's a good thing...

More plys is a very good thing.

Posted:

Tue Mar 29, 2011 12:30 pmby Miriam C.

I did 5'x5' Baltic Birch for the sides. I used 3/8" so a spline and biscuits were not realistic. I did a butt joint with a 1/4" ply to back the seam 6" on either side. Glued and screwed

It shouldn't come apart for a very long time.

Oh and using gorilla glue is a bad idea. Foams everywhere.

It shouldn't come apart for a very long time.

It shouldn't come apart for a very long time.  Oh and using gorilla glue is a bad idea. Foams everywhere.

Oh and using gorilla glue is a bad idea. Foams everywhere.