Glenn,

Regarding the hatch trim, I used the wide lip RV roof edge molding from Grant Whipp of Lil Bear Teardrops. I also used this trim along my roof and along the the bottom of the sidewalls.

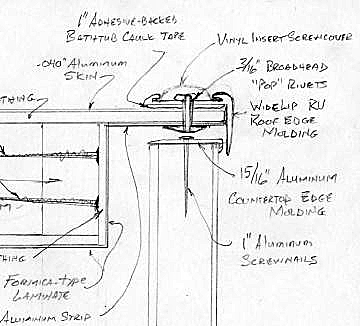

Here is a detail that Grant drew on how to install the trim.

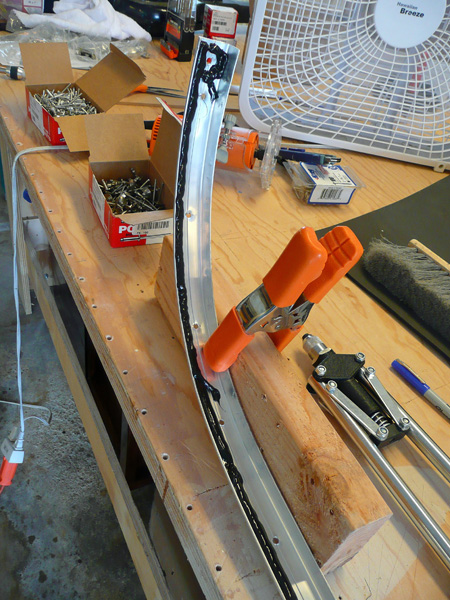

Depending upon the profile of your hatch, you will probably want to "pre-bend" the trim before installing it, especially if you use the wide lip profile. I formed the trim against a piece of scrap MDF cut to the profile of the hatch.

Once the trim is formed, hold or clamp it into place to drill holes for fasteners. I used wide head stainless steel rivets. Other use sex bolts and screws also known as barrel bolts and Chicago nuts. I added a strip of aluminum to the underside of the hatch. If you go this route, you'll need to pre-drill it too. (I glued the underside aluminum in place with 3M 4200 prior to drilling.)

There actually is a lip on both sides of the trim. (The bottom of the extrusion is not flat.) I hot-glued washers to some of the fastener holes are to keep the trim from "rolling" as I installed the rivets.

This is a picture of the hatch aluminum with holes drilled and washers glued in place just prior to installing the trim.

I then added sealant to the trim. You can see that the trim was pre-bent before installing.

These are pictures of the trim installed. The first is the underside with exposed rivet heads. The second is with the trim installed and hatch closed.

The only thing I might add is that I could not find wide head rivets in aluminum so I purchased stainless steel. When I tested the SS rivets on scrap, I found out that a standard rivet tool, at least for me, did not have enought leverage. I had to purchase a long-handle rivet tool.

I hope this helps.

Take care,

Tom