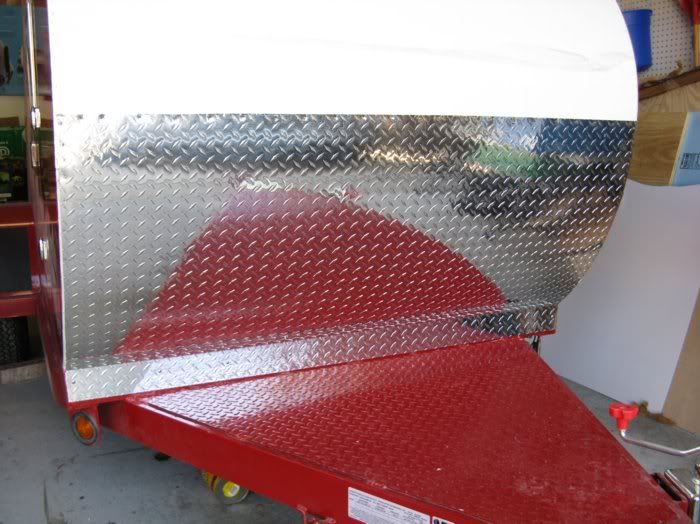

Diamond plate rock guard.

I like the look of a diamond plate rock guard, and it should go well with DP fenders and tongue box. Just a few questions.

1. How tall did you make it?

2. How did you attach it?

3. How did you trim it?

If it helps, I have a Benroy profile.

1. How tall did you make it?

2. How did you attach it?

3. How did you trim it?

If it helps, I have a Benroy profile.

Try to find a business that may have "drops" available. You're not going to need the whole sheet.

Try to find a business that may have "drops" available. You're not going to need the whole sheet.