Page 1 of 1

framing alternatives???

Posted:

Wed Oct 26, 2011 8:30 pmby working on it

[I'm no carpenter. Biscuits,Dovetails,Spars,Rabbets etcetera are all foreign to my experience. I am a bolt in screw down weld on kind of guy. I need to use systems I am familiar with. Hence my questions:] Since I'm building (basically) a 4'x8' mini-hopper, with no curves or radii, and the trailer itself is rigidly welded rectangular tubing, I wonder if alternatives to spars and standard bracing would be viable ? I am considering using Simpson Strong-Ties and PL adhesive as my primary bracing/joining system. I have used them (SST)for several projects before,including free-standing and load-bearing structures, and they are still standing square as built, and I am sure of their durability.. There are several SST pieces that can be used for joining straight and angled wood components, and the PL adhesive "cements" it all together. The floor is 4'x8'x1/2" Birch ply (with 1/4" luan overlay for extra strength/moisture protection), the walls 1/2" ply/exterior covering TBD , and the roof (2 pieces, both sloped but flat) of the same material. The only places that would need a box frame would be at front ,center,and rear to support the roof. or Could 1"x2"x8' pieces be used as nailers between the aforementioned box-framed areas, with a X brace at each end? Simplicity and strength by either method? Or must I try to build the conventional way? Comments please !!!

Posted:

Thu Oct 27, 2011 10:41 amby CarlLaFong

The learning curve for a Kreg Jig is about 20 minutes

Posted:

Thu Oct 27, 2011 11:30 amby bobhenry

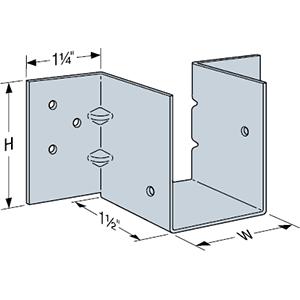

If you still want side to side spars here are a couple choices offered by simpson........

A face mount

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

an an underslung top bearing mount

Posted:

Thu Oct 27, 2011 12:23 pmby CarlLaFong

I've used a lot of Simpson products in construction. I'm not sure they are available in sizes appropriate for the 1/2 and 3/4 inch materials that are commonly used in trailer construction. There are very few specialized joints or skills needed to build a trailer. None of the wall to floor or wall to spar joints are anything special, in most of the builds that I have studied. Again, I would buy a Kreg or similar jig. Pocket hole joints are very strong, accurate, light weight and simple. Simpson connectors are heavy, awkward and it's difficult to maintain the sort of accuracy you want for a trailer. If you're going to add cabinets to your build, then you are going to have to develop some woodworking skills anyway. There are lots of good tutorials on You Tube. Somerfeld tools also has a great line of DVDs on cabinet building. A trailer body is little more than a big cabinet

Posted:

Thu Oct 27, 2011 12:33 pmby Lgboro

I bought a Kreg but have used biscuits and dowel pins exclusively, The only mechanical fasteners I will have will connect the box to the trailer and to secure windows, doors, vents and molding. The torsion box that is formed by build is so strong I can't imagine a weak point with any properly built tear not matter which fastener is used.