Page 1 of 3

So how big of an issue is water damage?

Posted:

Thu Dec 15, 2011 3:31 pmby Robbie

I guess what I'm really wondering is how possible or likely is water damage? Reason I ask is I have seen some debate in other threads about the effectiveness and worthwhileness of CPES, which is what I was planning on using on the exterior of my teardrop before the aluminum goes on. I'm starting to wonder if it is actually going to be necessary? Or if an alternative like a good few coats of primer/sealer would be enough. The outer edges of my plywood walls will be sealed with Poly Roofing sealant at the bottom and the Poly Construction adhesive between the luan skin and top edge. So the only place I could imagine as a high water contact area would be the door opening which will have aluminum trim and Poly Construction adhesive/sealant all the way around it. The entire bottom of the trailer has roofing tar over it and 1" insulation so I have no worries of water damage there. .032 aluminum will cover the entire exterior with a good sealant/butyl tape at any openings.

I guess I'm asking if there is a cheaper alternative to sealing the plywood skin and if such a sealer, like epoxy, resin, etc., is necessary for this build? The trailer will be tarped AND in a little tarp style garage through the winter so no moisture will be on it then. The only real water scenario I could imagine is driving in rainy wet conditions and some rain while camping. But never a long term soaking.

Any tips, advice, or whatever is always appreciated!

Robbie

Posted:

Thu Dec 15, 2011 3:46 pmby glenpinpat

mine is completely covered in aluminum. The only wood that is exposed around the doors. We painted the plywood with an exterior grade paint before covering with aluminum. In 2 years we have had no problkems with wood rot or wood expanding because of water. Our trailer is stored outdoors all year, so it gets wet. Like you i have asphalt stuff on the bottom and 1" insulation. Patrick

Posted:

Thu Dec 15, 2011 4:19 pmby Robbie

Thanks Patrick! So you only have the exterior paint under the aluminum? No kind of epoxy or anything else?

Posted:

Thu Dec 15, 2011 6:36 pmby CarlLaFong

I'm amazed at how overbuilt most of the TTTs that I see on this site. It is not, entirely, a bad thing, don't get me wrong. Frames built from 1/4 wall tube, crossmembers 8 inches on center, etc. I worked, many years ago at Santa Fe and Traveleze. The walls were made of cheap, 2X2 Doug fir, held together with staples. The interior walls were cheap paneling with more staples and a few globs of Liquid Nails here and there. The exteriors were aluminum siding and more staples. The openings were cut out with routers, everything was sealed up with putty tape and there you were. The least talented, backyard, builder, here, is probably putting together a better product than we were back in 71. We had no skills, to speak of. Mostly kids with their first job, illegals, druggies and ex cons. I applaud the use of all of these high tech products, jigs, techniques and super attention to detail. I will use many of them, if I ever get to my build. I would think that a well built, aluminum clad trailer is, at the very least, a 20 year product without any additional sealing or application of various goops. In my mind, so far, mine will be clad in alloy. It will, also, be pocket screwed, glued and gooped to within an inch of it's life.

Posted:

Thu Dec 15, 2011 7:21 pmby Shadow Catcher

I have often said when I first started looking at finding/building a teardrop I stared looking at what fails and in order it is wood and steel. Current trailers/RV's are for the most part no better built than the Santa Fe, and they fail.

Compass Rose has a Filon exterior and aluminum frame and what wood there is, is well protected.

you can not do too much to protect your tear, unless this is only the first one

Posted:

Thu Dec 15, 2011 7:29 pmby Robbie

This is all great info! Thanks guys. I am thinking right now of doing 2 or 3 coats of the kilz 2 primer/sealer on the entire exterior and ditching the CPES. I wanted this to be a budget build and its turning into anything but that. LOL. Of course this is our first trailer and I do plan on building another in the future but I'm thinking with the use it will get and the covered storage the primer should suffice. Maybe on the next one, which will be bigger and more elaborate, I will budget for the epoxy as we'll probably keep it for a lot longer than we will this one.

Posted:

Thu Dec 15, 2011 7:47 pmby len19070

I've restored many vintage trailers in my career.

And the one thing I have noticed is that several manufactures don't understand the concept of Gravity!

Placing a lower piece of siding/roofing OVER an upper one and depending on a Sealant of any kind to protect it over the years is just asking for disaster.

And yet I see it every day even on New units.

Fortunately the majority here understand it.

Just "think like water" and try to shed it as you do your build.

Sounds like "DUH" advise but it does have merit.

Happy Trails

Len

BTW, Window "Drip Caps" help a lot.

Posted:

Fri Dec 16, 2011 4:29 amby 48Rob

I would think that a well built, aluminum clad trailer is, at the very least, a 20 year product without any additional sealing or application of various goops.

when I first started looking at finding/building a teardrop I stared looking at what fails and in order it is wood and steel. Current trailers/RV's are for the most part no better built than the Santa Fe, and they fail.

Please don't take this wrong as I mean no disrespect, but your comment above is the way most people feel, and why so many trailers go bad.

a 20 year product without any additional sealing or application of various goops

While Aluminum siding will last a long, long time, the number one reason trailers leak is from lack of annual inspections/maintenance.

99% of all leaks start out very small, and get larger, and worse over time.

Usually by the time you notice damage inside, there is major damage in the wall/ceiling framing.

As you discovered Carl, you can slap something together with the cheapest materials and questionable construction methods and it will hold, but give water the slightest chance and the trailer, no matter the recycled back yard build, or a hundred thousand dollar factory built will crumble.

Rob

Posted:

Fri Dec 16, 2011 5:25 amby glenpinpat

That is correct I have only exterior paint under the aluminum. But I will agree that you must think like water and make sure no water gets in under the aluminum. We sprayed yours with a water hose under pressure just to imitate driving conditions before we finished the interior just so we could find any water leaks.

Posted:

Fri Dec 16, 2011 8:31 amby Oldragbaggers

I am epoxying mine to death, CPES and fiberglass cloth on the outside, then polyurethane marine paint. The road side of the floor has CPES, fiberglass cloth and then asphalt emulsion.

I know there are many who would say that is way overbuilding, and I am sure they are correct. But I know how insidious water can be. I've seen what can find it's way inside and the damage it can do. And bear in mind, sometimes the spot where you see the water damage show up can be a long way off from the actual entry point, so finding the source of the problem once it occurs is not always easy.

My thought is, better to ward off any problems as best you can in the beginning. A lot of times it is more expensive in the end to take something apart and fix it later (plus time wasted you could be playing.) Besides having it be dry and last longer, I think this will also cut down on maintenance.

Posted:

Fri Dec 16, 2011 11:57 amby aggie79

Robbie,

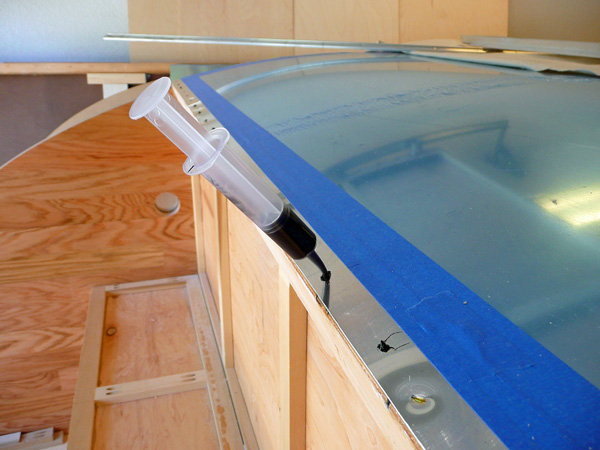

Although I epoxied prior to applying aluminum, in hindsight I think any protective coating on the plywood should be sufficient. In my opinion, the real challenge in using aluminum over wood is how to seal possible water infiltration at fasteners, seams, and around the trim.

I used a sealant around the perimeter of the aluminum sheets and at seams.

Then, I removed the temporary fasteners, "injected" sealant using syringes, and then installed the permanent fasteners.

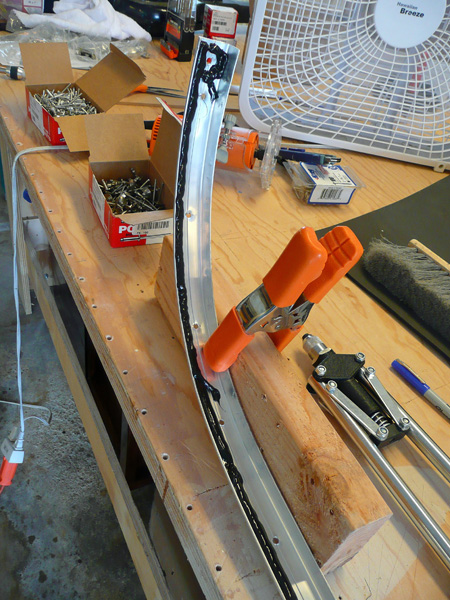

For trim, I fitted it and temporarily attached it to the profile. I then removed the trim and added a bead of sealant to the trim. The screw holes were filled with sealant and then the trim was permanently installed.

So far everything has remained watertight.

Take care,

Tom

Posted:

Fri Dec 16, 2011 12:51 pmby Robbie

Thanks for the pics Tom! What kind of sealant did you use there? I was planning on doing my aluminum install pretty much the same way you did yours will sealant at all the perimeter edges and then overlapping the aluminum where the sheets will meet on the top. I was also thinking of applying the sides first and then putting on the roof skin and bending the edges of the roof skin over the top edge of the sides about a 1/4". But seeing as I have the front and rear bends in my profile I'm debating whether that would be worth the trouble.

I'm starting to consider just getting a smaller CPES kit and doing the CPES around everywhere there is a seam/edge of the aluminum and then 2 coats of primer/sealer over the entire thing. That way all the possible leak locations will have the epoxy but I don't think the CPES in the field is really necessary.

Posted:

Fri Dec 16, 2011 1:18 pmby Oldragbaggers

Beautiful job sealing it up Tom. You should be good to go for a long long time.

Posted:

Fri Dec 16, 2011 2:07 pmby CarlLaFong

48Rob wrote:I would think that a well built, aluminum clad trailer is, at the very least, a 20 year product without any additional sealing or application of various goops.

when I first started looking at finding/building a teardrop I stared looking at what fails and in order it is wood and steel. Current trailers/RV's are for the most part no better built than the Santa Fe, and they fail.

Please don't take this wrong as I mean no disrespect, but your comment above is the way most people feel, and why so many trailers go bad.

a 20 year product without any additional sealing or application of various goops

While Aluminum siding will last a long, long time, the number one reason trailers leak is from lack of annual inspections/maintenance.

99% of all leaks start out very small, and get larger, and worse over time.

Usually by the time you notice damage inside, there is major damage in the wall/ceiling framing.

As you discovered Carl, you can slap something together with the cheapest materials and questionable construction methods and it will hold, but give water the slightest chance and the trailer, no matter the recycled back yard build, or a hundred thousand dollar factory built will crumble.

Rob

of course I took maintenance and, necessary, repair into account when I made my statements. The additional goops and sealants that I spoke of was refering to something that might be done during assembly, at the factory, rather than re sealing as a part of general maintenance. We have a 1989 Layton fifth wheel, built as I described, with sticks and staples. It has held up well, but I do have to check things out periodically. I have had some water intrusion that I have had to address, but for being 23 years old and spending every day of it's life sitting outdoors, it's in fair shape. Additionally, as I stated, When, if ever, I get to my build, I will not be slapping it together as we did at Santa Fe. The cabinet maker in me will not allow it

Posted:

Fri Dec 16, 2011 4:40 pmby aggie79

Robbie wrote:What kind of sealant did you use there? I was planning on doing my aluminum install pretty much the same way you did yours will sealant at all the perimeter edges and then overlapping the aluminum where the sheets will meet on the top. I was also thinking of applying the sides first and then putting on the roof skin and bending the edges of the roof skin over the top edge of the sides about a 1/4". But seeing as I have the front and rear bends in my profile I'm debating whether that would be worth the trouble.

Robbie,

I used 3M 4200 marine sealant. It's good stuff but anything with "marine" and/or "3M" in the title means it is expensive - about $12 per tube.

Although the 3M 4200 is "removable" I didn't use it around my windows. I used the standard butyl tape so I could remove them in the future if needed. After squished out and then set for a few weeks, I trimmed the tape and followed up the edges with OSI gutter sealant that I got at the BORG.

The reason for the long-winded explanation above is that knowing how good the OSI worked - at about $4 per tube and available locally - I would use that instead of the 3M 4200 in the future.

Take care,

Tom